Three partners from Brabant, one vision. Technology in balance with heritage

The Tinbergen Building on the Woudestein campus of Erasmus University Rotterdam is a striking example of brutalist functionalism from the period 1963-1970 and was designed by Cornelis Elffers. After more than fifty years of intensive use, this municipal monument is undergoing a thorough transformation into a future-proof educational and office building. Within the construction team, Van Delft Groep plays a key role in the field of mechanical engineering installations.

The project is being carried out by three companies from Brabant: Berghege Heerkens Bouwgroep (construction), Hoppenbrouwers Techniek (electrical engineering), and Van Delft Groep (mechanical engineering). “It's remarkable that three regional companies are working together to renovate such a complex monumental building,” says Marcel de Graaf, project team leader at Van Delft Groep. “The collaboration is going very well, partly thanks to joint lean planning in which the phasing and milestones are clearly defined.”

New technology for an old building

The original installations date back to 1968 and no longer met today's requirements. “The building was heated by a traditional collective district heating system and radiators. In the future, heat and cold will mainly be generated by heat pumps powered by a thermal energy storage system and distributed by a climate ceiling,” explains De Graaf. “The Tinbergen building will be equipped with several heat pumps that will provide heating and cooling for the entire complex. The surrounding university buildings, which were previously connected to the same system, will also be reconnected to it.”

During the renovation, the existing installation had to be shut down. Van Delft Group therefore set up a temporary technical room in a container configuration in its own workshop. This currently provides the surrounding buildings and server rooms with heating and cooling until the new installation is operational.

Technical precision

The technical room will be located on the HT (basement/ground floor) and eighteenth floors, where an extra layer will be added to the building. “That requires a lot of coordination,” says project manager Jan-Willem van Bokhoven. “We are dealing with an existing structure in which approximately 3,500 recesses will be drilled. Everything has been modeled in BIM, so we know exactly where pipes, ceilings, and recesses come together.” Climate ceilings are used inside the building; all pipes are neatly concealed in the existing shafts. “No visible installations, but a high-quality finish that matches the monumental appearance.”

Prefab as an accelerator

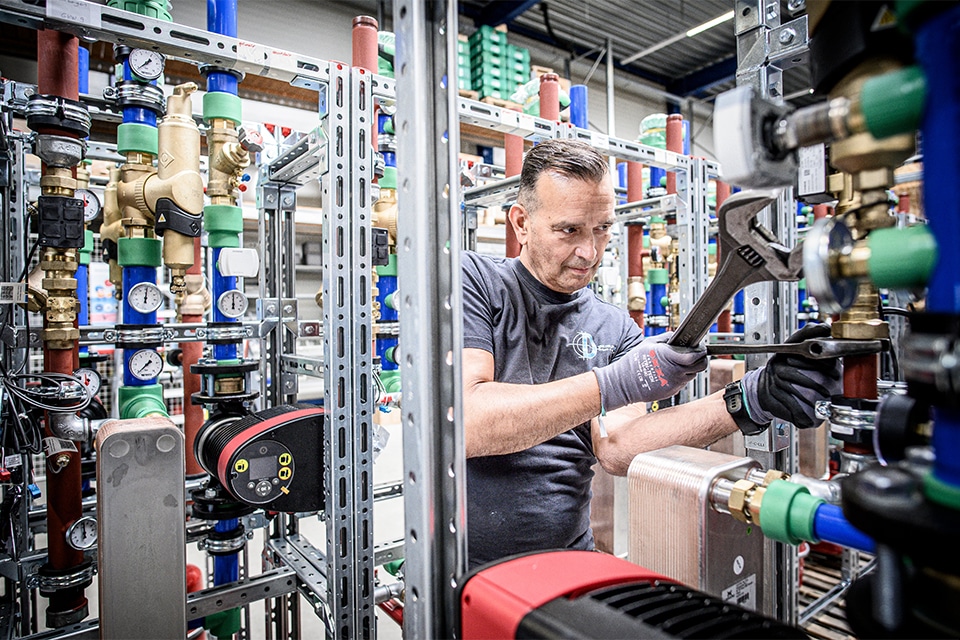

An important factor in the success of the project is the decision to use prefabricated installations. At its workshop in Nieuwkuijk, Van Delft Groep produces complete distribution sets and pipe modules that can be installed on site in a single operation. “The building has nineteen floors, sixteen of which are virtually identical. That makes prefabrication ideal,” says De Graaf. “We reduce the number of technicians on site, limit transport movements, and increase quality. Everything that leaves here has been tested and is ready for immediate installation.”

The distribution sets are supplied as prefabricated skids: steel frames in which all the technology has already been assembled. “Each floor will have its own distribution station,” adds De Graaf. “In total, we will install forty distribution stations in vertical pipe shafts, each controlling its own heating and cooling circuit. Because we assemble and test the skids here in the workshop, we can quickly install and connect them on site. That saves time, space, and risks.”

A major project

The size and complexity of the Tinbergen Building make it a landmark project for Van Delft Groep. “The scale, technology, and collaboration with other parties come together perfectly here,” concludes De Graaf. “We are bringing a building from 1968 up to the standards of 2026—with respect for the past and an eye to the future.”

Heeft u vragen over dit artikel, project of product?

Neem dan rechtstreeks contact op met Van Delft Group.

Contact opnemen

Contact opnemen