Many details, unusual curves and great heights

With the completion of the new logistics center with headquarters of Van Mossel in Waalwijk, DAS Bouwsystemen has another great reference. Commissioned by Bouwbedrijf van de Ven, the Drunen finishing specialist realized all metal stud pre-walls, wooden ceilings, system ceilings and fixed ceilings in the workshop, offices and porter's lodge. "A high level of finishing was required," says Project Manager Robert Assink. "Craftsmanship was necessary to get all the details right and to achieve the desired curves. But also to guarantee assembly at high heights and within foreseeable time."

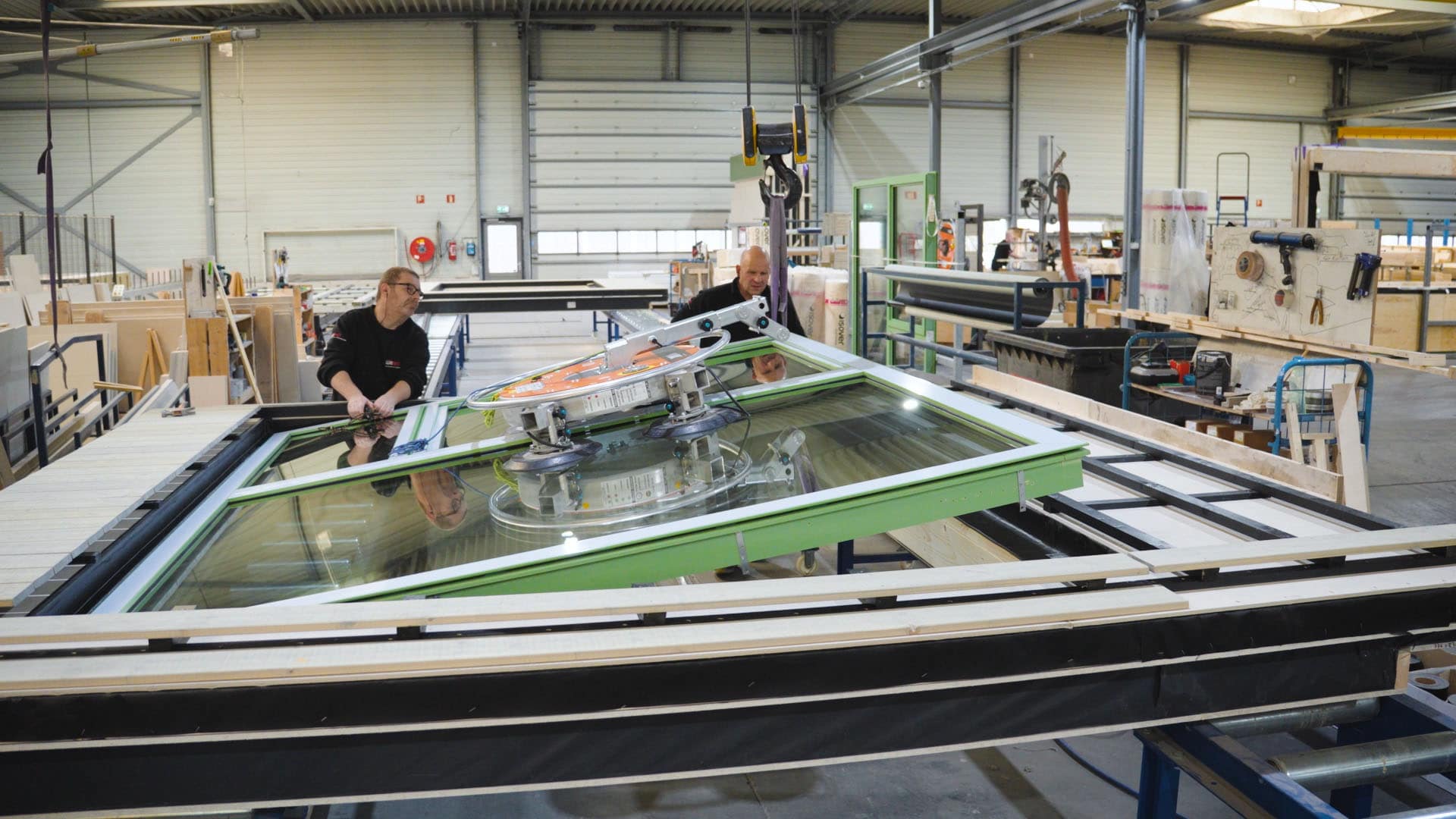

"The walls in the workshop are up to 10 meters high," Assink says. "Moreover, our mechanics had to work between the steel trusses. To make this possible, we divided the framework into sections. Then, from an aerial platform, we filled in the stile field and processed the drywall." Also special are the round walls, round balustrades and round coves in the new building, he says. "Based on the dimensions from the drawing program, we had wooden shingles milled, which served as a base for the wall finish. And the steel staircase was also fitted with battens all around, to which thin plasterboards were attached in the right curve. On the underside of the stairs, we had a stucco mesh reinforcement mesh with a fine mesh applied, after which the stairs received a high-quality stucco finish."

In the auditoriums, DAS Bouwsystemen applied acoustic baffles to ensure pleasant room acoustics. "We also created pressure baffles above the band grids, under which demountable walls were placed. This preserves Van Mossel's flexibility and freedom of layout, but prevents sound transmission from one room to another."

A multitude of detailing comes together in the new building, Assink emphasizes. "For all the elements to fit together perfectly, a good design and careful coordination were essential. We invested a lot of time in the work preparation. Moreover, regular consultations with relevant parties were scheduled. We made several test pieces and our supervisors Arjan Hessels and Pieter van der Hoogt constantly kept a finger on the pulse. This allowed us to realize the project well, quickly and in a very pleasant cooperation. When you walk through the building now, you can see that the end result is stunning."