Building at lightning speed

Ready-made modules from our own production site

Daiwa House Modular Europe built an apartment complex for mixed housing in Tilburg at lightning speed called 't Kompas op Zuid. The homes are intended for emergency seekers and people who have successfully completed a care program and can live independently again.

"The clients asked us to build 96 temporary two-room apartments modularly. In 10 to 15 years, the units can be removed or moved again," says work planner Rowin van Schaik of Daiwa House Modular Europe. "The building is five stories high and includes a meeting area with a communal kitchen. There is also a covered bicycle storage area attached to the building."

Last August, the company started producing the modules at its own production site in Montfoort. Each apartment consists of two units of 6×3 m and has a total surface area of 32 m2. Van Schaik: "The sewer pipes are supplied by the installer and we pour them under the floors. We have the bathrooms prefabricated. These are a room in itself with walls, floors, ceilings, toilet and shower. We place them in the unit at the factory before the roof goes on. The kitchens are delivered to our assembly hall and we also install them ourselves."

Extremely short construction time

This method of construction allows the project to be realized in an extremely short time. The modules were produced in nine weeks and the first were installed in October. The building will be completed in early 2024, after being fitted with wooden cladding. Daiwa House Modular Europe takes care of the complete process: from production to installation and completion. On site, the most important part of the work is making the roof wind and watertight. Then the down pipes are connected and the corridors are finished with floor, ceiling and wall finishes. But the company thinks along from the design phase. "We then look along at the front end to see what is possible with a design using our construction method. We make the working drawings, which are also needed for the permit application. In addition to the apartments, the corridors, stairwells and elevators also consist of modules."

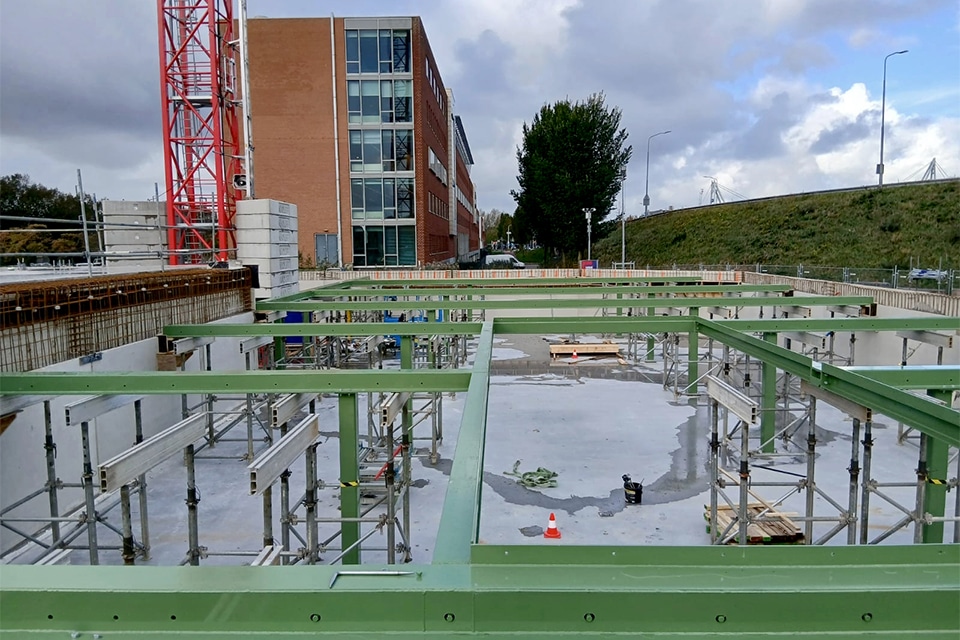

Steel frames as the main supporting structure

The floors of the modules are made of concrete, the walls of wood frame elements. Each module has a steel frame that collectively functions as the main load-bearing structure. Although modular construction is the core business of Daiwa House Modular Europe, it is still special to see a complete building in four weeks, Van Schaik believes. "If you haven't been to the construction site for a week, there is already another whole building layer. In this case it was especially fast: we already started placing while production was still running. We placed sixteen modules per day here, but depending on the construction site and logistics, we could place as many as 24 per day."

The modules were brought to the construction site in pairs on a truck with a trailer. There, the construction company used a special lifting frame to hoist the units into the building. This is done fully automatically, which improves speed and safety. Modular construction is sustainable in itself because the modules can be reused for other purposes. There will also be 240 solar panels on the building, which will be individually connected to the homes depending on their energy needs.

- Client Tiwos Housing Foundation

- Contractor Daiwa House Modular Europe