Blow-in wool offers thermal, acoustic and fire protection benefits

Insulation to blow in

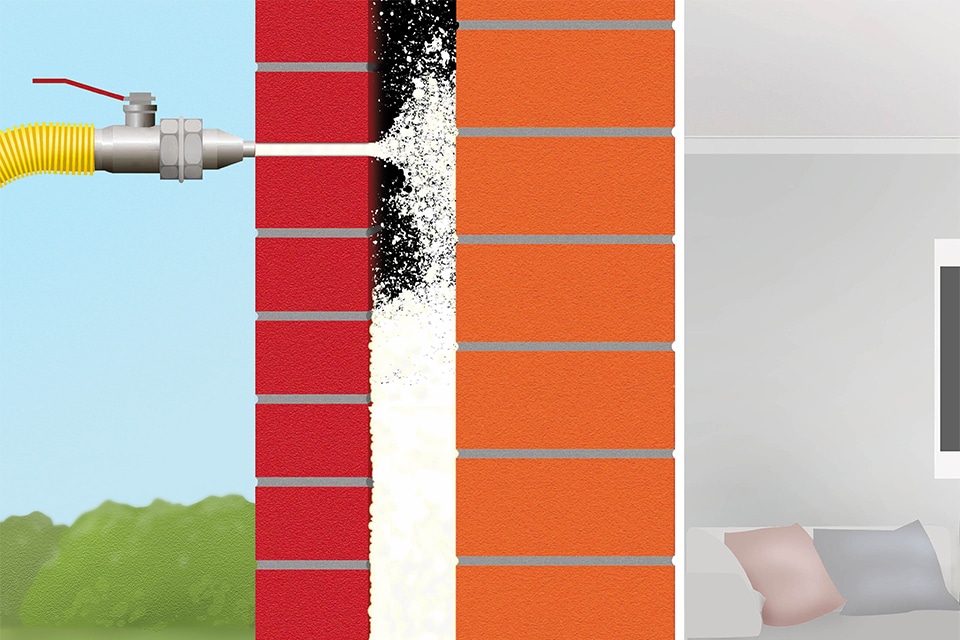

The blow-in method is gaining ground in post-insulation. Two parties involved tell how they work with URSA's blow-in glass wool: "This material has good thermal, acoustic and fire-resistant properties."

There is a great deal of sustainability to be achieved if all cavity walls that are currently empty were to be insulated. For many people, it is obvious that the blow-in method offers great advantages in post-insulation. With blow-in, there is no need to cut insulation boards to size: blow-in materials fill the space in all corners. An additional advantage when post-insulating a roof is that no vertical transport is required, as the blow-in machine can remain downstairs, with only the hoses being brought up. "We like to use URSA's blow-in wool for this," says Freek Martens, owner-director of Comfort Insulation. His company has been in the insulation business for more than five years. "We do this with an ambitious and young team. We recognize how important our work is: with insulation we make the Netherlands a bit more sustainable and provide comfortable living spaces."

Insulation Expertise

Herald van Zijl, account manager at The Insulation Shop, adds: "URSA blown-in glass wool is very suitable for the thermal insulation of cavity walls of buildings that were built in the 1960s, 1970s and 1980s and, as was common at the time, had little or no insulation." URSA, active in more than 20 countries, is a European leader in mineral glass wool and extruded polystyrene (XPS) insulation materials. Since 2022, it has been part of Etex, a global pioneer in lightweight construction.

Thinking along

Martens shows how working with the blow-in wool works in practice. His company took care of the insulation of the meeting center of the Buddhist organization SGI Netherlands, the "Ikeda Center for Friendship and Peace" in Amsterdam-Osdorp. The building in question on Osdorper Ban had been built in the 1960s as a Roman Catholic church. Martens explains, "Our client's primary wish was to improve the thermal insulation. In addition, there was an express wish to improve the acoustic values as well, with a view to using it as a prayer room. It was important to pay attention to fire resistance as well." Van Zijl adds: "These are precisely the properties that URSA's blow-in wool scores so well on: its product offers thermal, acoustic and fire resistance insulation. When we are working on a project, URSA is always willing to think along with us, to provide us with a solution that allows us to help the customer quickly."

In practice

Martens: "The Buddhist center in Amsterdam-Osdorp has a facade of over a thousand square meters, which we provided with post-insulation with blow-in wool. Before we can insulate such a facade, we first inspect it. We use an endoscope to examine the cavity wall from the inside. To do this, we drill bore holes scattered around the wall according to a certified drilling pattern. Once we have viewed the interior space of the cavity wall with the endoscope, we can start insulating. To do this, we adjust the blow-in machine and blow the blow-in wool into the wall through the drill holes." Martens shows and hears the result: "Inside is now much more comfortable, both in terms of acoustics and temperature. We have thermally, acoustically and fire-safely insulated this meeting center, thanks to URSA's blow-in glass wool."

Heeft u vragen over dit artikel, project of product?

Neem dan rechtstreeks contact op met URSA Benelux.

Contact opnemen

Contact opnemen