Efficient rainwater drainage for VDH in Ridderkerk

Especially with large roofs, the rainwater drainage must of course be properly regulated to prevent flooding and damage to the roof structure. For the new and state-of-the-art distribution center of VDH Forwarding & Warehousing in Ridderkerk, this important task was awarded to Aquadraat, which realized several rainwater filling systems including emergency drainage systems.

Commissioned by Aannemingsbedrijf Fraanje B.V., Aquadraat took care of the design and 3D elaboration, production and assembly of the complete rainwater drainage system. It was also responsible for quality control, Frank van Dommelen explains. "The distribution center of VDH Forwarding & Warehousing is a unique project, because of the shape and sloping sides of the rear facade. As a result, we were not able to go directly with the rainwater drains to the front facade, in order to drain the rainwater efficiently. Instead, over two hundred meters of underground piping was used. In the preliminary phase, we had regular contact with Aannemingsbedrijf Fraanje B.V. to determine the right approach for this, on the basis of which the rest of the system was also worked out."

Rainwater full-fill system

Rainwater full-fill systems were chosen in this project. "Both for the standard rainwater drains and for the emergency drainage systems, which can assist in case of heavy rainfall or in case of possible blockages in the basic system," Van Dommelen said. "Full-fill systems work with a negative pressure, which has a suction effect on the rainwater on the roof. Because no air flows through the pipes, this water can be sucked off the roof with great force through gravity and vacuum action." A major advantage of full-fill systems is that smaller diameters can be worked with, he says. "Especially in this project, this is a godsend because of the limited installation space above the cold rooms."

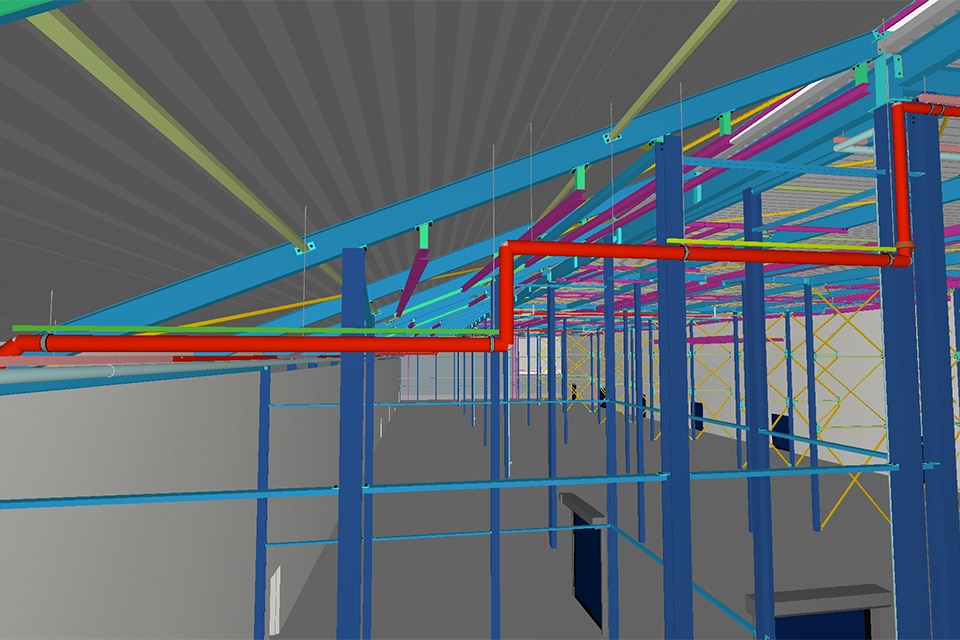

Cantilever mounting

Aquadraat designed specific roof hoppers for the rainwater and emergency drainage systems. "Under the roof, a net of HDPE pipes hangs on a rail system we developed in-house, which allowed us to mount cantilevered," said Van Dommelen. "This means we did not necessarily have to mount to the roof panels. Because our pipeline route has many interfaces with the other installations, we had to coordinate our work very closely. Especially in combination with the limited installation spaces. The 3D design helped with this." To monitor the tight schedule, Aquadraat's superintendent coordinated all work almost daily with the on-site superintendent, resulting in a smooth execution.

At the end of April, Aquadraat completed the final work. "Once the distribution center is heading toward completion, we will come back one more time for the completion round and to put the final touches on the 'i'."

Thermal and acoustic insulation

The rainwater on the roof of the VDH distribution center goes directly through transport pipes in the hall and under the floor to the ground pipes, which go out both to the left and right of the building, Van Dommelen says. "Here the ground worker takes over the transport, with all rainwater being conveyed to a wadi or the municipal sewer." All rainwater drains are additionally insulated by Aquadraat to prevent condensation. "In the area of the offices, we also installed acoustic insulation."

Quality control

"To demonstrate the quality of the systems, all the rainwater systems were filled with a formation gas immediately after assembly, after which we checked all the couplings for any leaks," he concludes. "The resulting reports are added to the As Built file upon completion and handed over to the client. Thanks to this method, our leakage rate is almost zero AND we fully comply with the desired quality control."