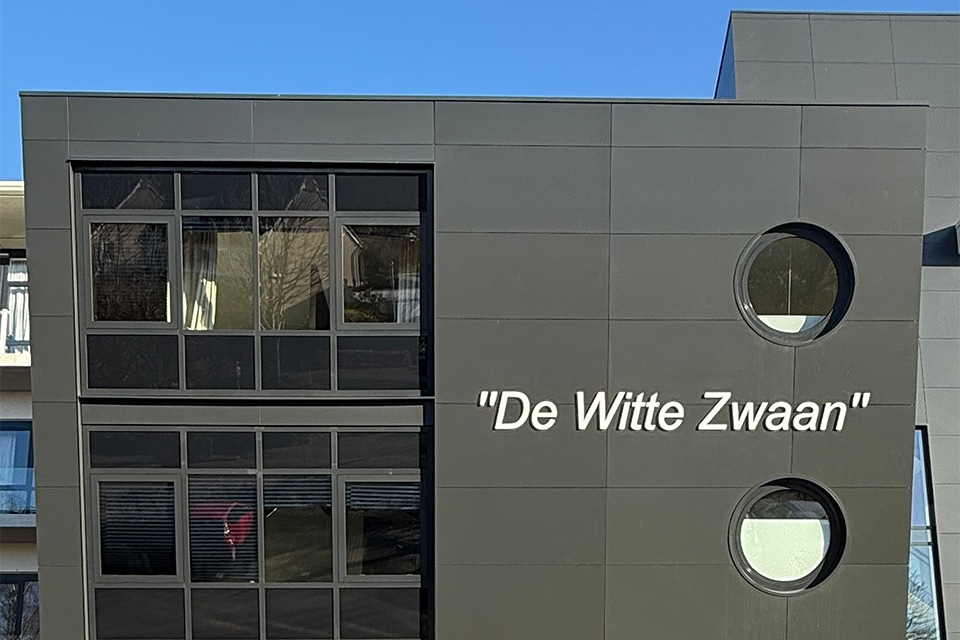

Classy window frames for village icon The White Swan

From office to characterful living

With approximately seventy professionals and its own factory, coating facility and showroom, Lieftink Geveltechniek has everything needed to make projects a success. “We think along in the design phase, look for smart solutions and always find the balance between aesthetics, technology and budget,” says sales manager Jarno van der Graft. “Both in new construction and renovation projects, of which De Witte Zwaan in Lisse is an excellent example. Thanks in part to our high-quality window frames, this former office building is now perfectly suitable for residential use.”

Lieftink Geveltechniek was involved in this project by regular partner Interplan Bouwsupport. “Based on the architectural design, we prepared a quotation for the facade frames on the entrance side,” says Van der Graft. “After approval, we immediately started on the drawing work, on the basis of which, together with Interplan Bouwsupport, we coordinated, among other things, the dimensions, constructional connections and structural frames. Moreover, the drawing work formed the basis for our production.”

Aluminum truss and round tumbler windows

In total, Lieftink Geveltechniek produced and delivered approximately 400 m2 of aluminum window frames for the facade. “A special assignment because this facade tilts slightly forward,” said Van der Graft. “Revolving parts are not desirable in that case because they do not stay open properly.” A nice alternative was found in so-called tumbled windows, some of which are even circular, explains Engineer Bjorn Luik. “In addition, all window frames were powder-coated with pre-anodization, giving them optimal protection against the salty sea climate. RAL 7021 (black gray) was chosen as the color finish.”

Flexibility as a key to success

The basis of all window frames is Schüco's Low Carbon AWS 65 profile system, which excels in thermal and acoustic insulation as well as providing a flat appearance. “A godsend in renovation projects where the installation space sometimes differs from the drawing,” says van Der Graft. “As is typical for renovation projects, flexibility was also a must in Lisse. Both in the factory and on the construction site, where together with Interplan Bouwsupport we determined the starting points for the dimensions. This enabled us to guarantee smooth execution and fast assembly time.”

Service down to the details

As an additional assignment, Lieftink Geveltechniek also serviced the existing Schüco window frames at the rear of De Witte Zwaan. This included replacing rubbers and hardware, ensuring optimal operation for the long term, Van der Graft concludes. “Early this fall, we completed the final work.”