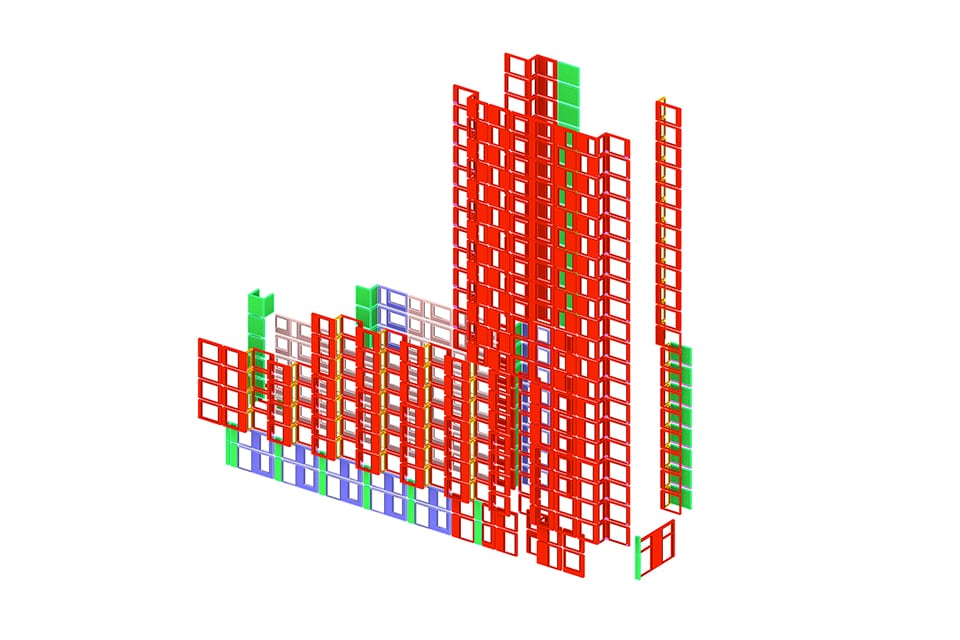

Wooden facade elements design, calculation and preparation in one BIM model

All links connected

VIANEN from Montfoort is ready for the next phase! The leading producer of wooden and wood-aluminum window frames and facade elements has been fully committed to digitization over the past two years. A nice step in this context is the development of parametric models, with which both the internal processes and the overall construction process can be improved and accelerated. "We are currently busy with the market introduction, with the aim of getting developers, architects and (developing) contractors on board with our new working method," says Oene Wassenaar, director of VIANEN. The basis of this new working method is the customer's own BIM model, which prevents communication noise and ensures that dimensions, materials, techniques, properties and quantities correspond perfectly. "As a result, quality and efficiency come together nicely."

Faster pricing

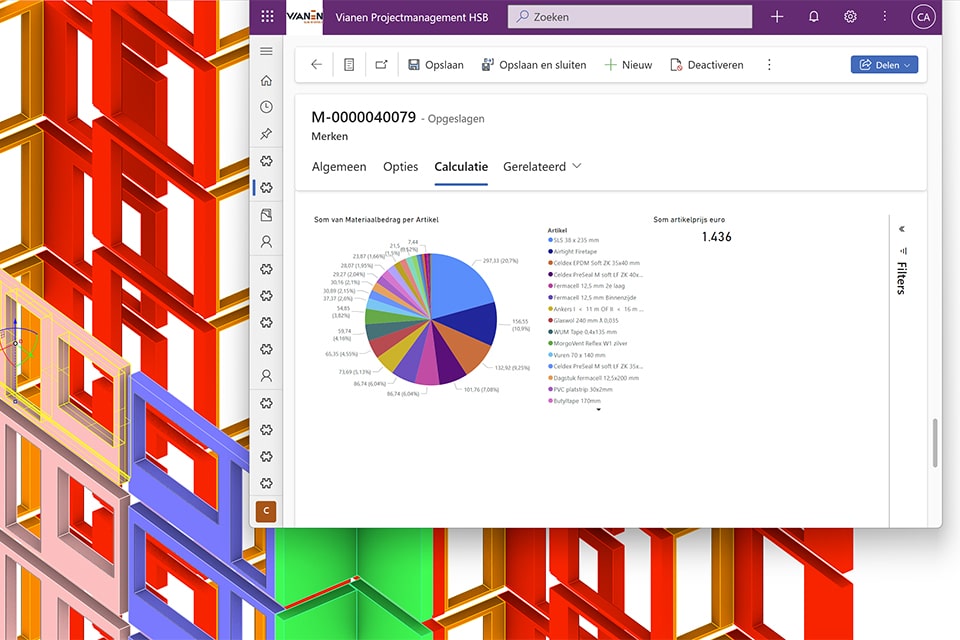

"We've been analyzing our customers' BIM models for a while now and see that their quality is getting better and better," says Wassenaar. "That's why we decided to use the BIM models from now on also for the quotation process of our prefab wooden façade elements. Quite a revolution, which saves our clients a lot of time. We can now digitally read and calculate our customers' BIM models in such a way that we can quickly extract a price from them. Simply by enriching the data from the model with our parametric product generator and digitally transferring it to our Microsoft Dynamics platform. This also allows us to simplify work preparation and production, through smart digital process integration."

Compare easily

Thanks to the new way of working, VIANEN sees even faster whether customers' BIM designs are suitable for its prefab and modular working methods. Is a project technically and economically feasible? Do the elements fit into the production line? And can the desired quality be achieved? "Because we digitally convert the supplied BIM model into a transparent quotation and also give it back digitally, customers can easily overlay the models," Wassenaar said. "This eliminates a huge number of time-consuming and error-prone strokes from the preparation phase. In addition, we can return valuable data. When the BIM designs are converted into manufacturable VIANEN elements, we can easily add and visualize automatically generated insulation values (Rc values). The same applies to material data, which says something about the environmental performance (MPG) of a building. This also simplifies the calculation of the MPG score."

Faster processes, lower cost

In recent months, Wassenaar has visited several customers to interpret the new way of working. "Our calculation software was developed in cooperation with Chris Aerts of software company AplusV Solutions. That's why Chris also joined us," he says. "In conversation with the customer's BIM modeler, nice new opportunities arose, which we are happy to pursue. Where we normally receive large packages of project information that have to be fathomed in a few days or weeks, the direct cooperation with the BIM modeler, for example, ensures direct exchange of the correct information. This speeds up processes and can reduce our cost price."

Essential building blocks for improvement and acceleration

Three building blocks are essential to accelerate construction processes, according to Wassenaar. First, he mentions digitization at the front end, so that the right modular building blocks are correctly incorporated into the BIM model and made accessible to the client. "This makes the feasibility of a project immediately clear," he emphasizes. "Does a design fit into our modular working method? And does the design meet the requirements of the Building Code and our certifications, for example with regard to high-rise projects?" Next, the assemblers on the construction site must be well informed about when and how the products will be delivered, he says. "But also about how the modules can be made wind and watertight as quickly as possible. This is also the next step in our working method. By supervising the complete chain including assembly and by connecting all the links, we can improve and speed up both production and execution."

All care out of your hands

Developers, architects and (developing) contractors alike appreciate this new way of thinking and working, notes Wassenaar. "Not surprisingly, because the facade combines excellent wind and water sealing with sophisticated sun, heat and cold regulation. Moreover, the facade defines the character of a building. By taking all these concerns off our hands, customers are relieved of a considerable burden. Especially in combination with our focus on sustainability and circularity. Where possible, we work with materials that are separable, renewable and reusable and have now started an LCA process to provide insight into our performance in this area. Both for our HSB façade elements and for our KLIMAATKOZIJN, which combines the good properties of wood and aluminum."

Heeft u vragen over dit artikel, project of product?

Neem dan rechtstreeks contact op met Vianen window frames.

Contact opnemen

Contact opnemen