Fire Station RTHA, Rotterdam | 24/7 in the starting blocks

Building with ascending and descending aircraft a stone's throw away

At Rotterdam The Hague Airport (RTHA), safety is paramount. An important part of this is the fire station, which is being built halfway down the runway. In case of emergencies, the three fire engines and support vehicles can turn out within 30 seconds.

The design of RTHA's fire station differs from the regular fire station in several ways. For starters, its location is anything but average. The construction site is halfway between the runways, ensuring that contractor De Vries Verburg Bouw's work falls under RTHA's rules and requirements. Because the fire station will soon have to be continuously occupied, there will also be additional facilities for the firefighters.

The location of the new fire station is anything but average.

Additional permits

Building at the airport requires many extra measures. "Our employees have direct access to the construction site," explains Bernhard van Houwelingen, project manager of De Vries en Verburg Bouw. "However, as soon as they need to be out there for a while, a work permit is required and they have to pass pass passport control and regular checkpoints. Additional permits are also required for placing equipment, such as pile drivers and cranes."

Preventing any ambiguity

The placement of the said equipment did not stop at permits. The location of the tower cranes also had to fit within the approach routes. From this followed the condition that the cranes can be lowered within half an hour in case of calamities. To eliminate any ambiguity for air traffic controllers and pilots, the cranes are equipped with a lamp and a red/white checkered flag.

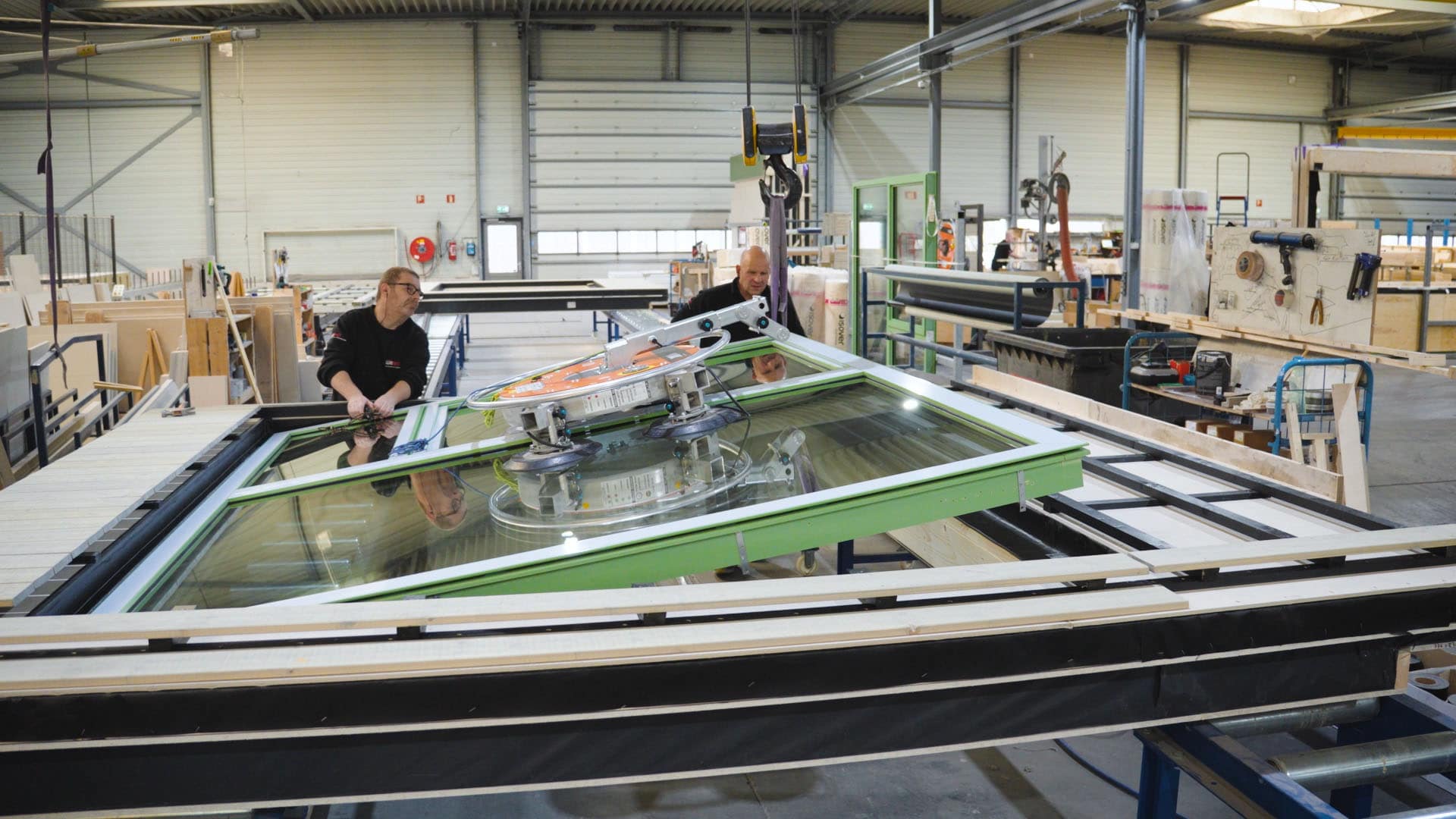

The facades will be heavily sound-insulated and fitted with special glass.

Support facilities

The operation of the fire station is driven by alarms from the control tower, the Airport Authority or the fire department control room via P2000. In order to respond to these immediately, the station is staffed 24/7. The firefighters pull into this and are in a continuous state of readiness. For recreation, sleeping quarters and a canteen are provided on the second floor; on the first floor, a gymnasium, fitness room, classroom and outdoor sports cage.

Crashtenders

"It took a lot of consultation to coordinate the alarms so that people in the barracks know how to respond to which alarm," Van Houwelingen says. "The collaborative processes must also be incorporated into the installations. Appealing examples of these special installations are the 'crash tenders,' or 'firefighting giants.' These engines are so powerful that they bring heavy fire engines to the scene of an incident within the shortest possible time. The firefighting giants are equipped with foam sprayers. To reduce air pollution when the crash tenders drive away, a special fume extractor is fitted."

High construction requirements

Otherwise, all building requirements are of the highest class. For environmental reasons, the roof will be equipped with sedum vegetation and solar panels. A greenhouse facade acts as a heating and cooling element. The facades will be heavily sound-insulated and fitted with special glass. "You would expect the special conditions to impact the construction process," notes Van Houwelingen. "The opposite is true. There are excellent consultations and the construction process runs smoothly. In addition, it is attractive to build in a place that would otherwise remain closed to you. The planes take off and land here a stone's throw away."