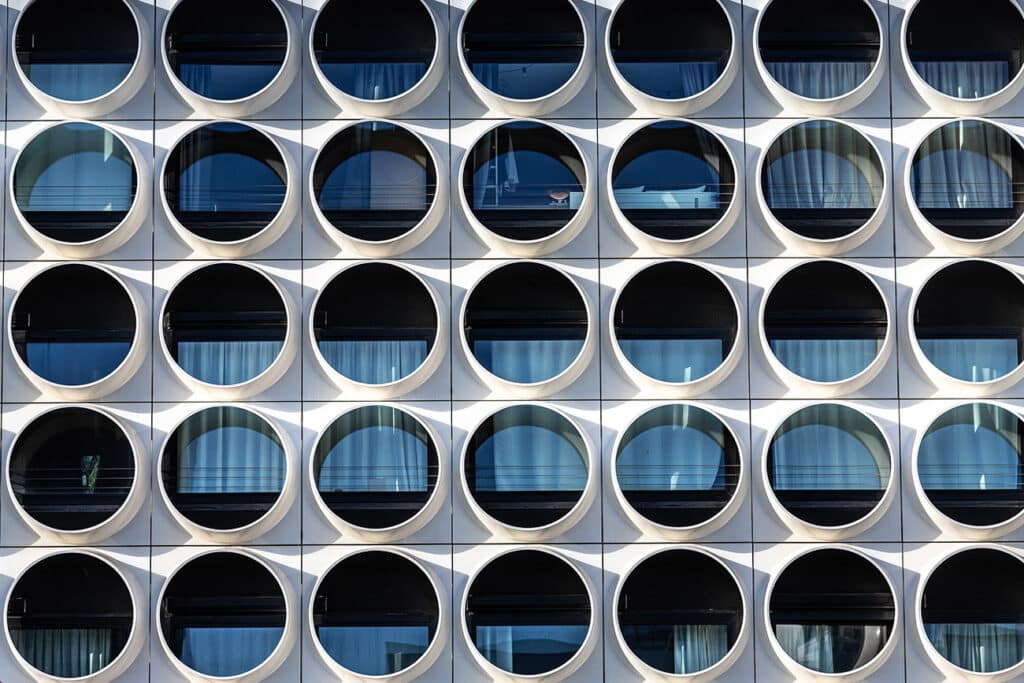

The facade quickly and securely wind and watertight with prefab glazed aluminum frames

That the construction industry faces major challenges is widely known. There is a huge amount of catching up to do because of the housing shortage, while there are also personnel shortages, expensive materials, long delivery times and the nitrogen and PFAS measures that construction is suffering from. "By working with precast in the construction process, we can meet many of these challenges," said Peter Visser, Production and Execution Coordinator at Intal.

Rudy Schipper, managing director of Intal, adds: "We have always been set up for prefab and modular construction and are making plenty of investments aimed at being able to deliver our products as completely as possible to relieve contractors and shorten the construction process."

Glazed frame with integrated mounting system

Schipper explains that Intal began providing glazed aluminum window frames back in 2003. "With our IntalFIX system, we have supplied many temporary housing and unit construction projects with our glazed window frames. So we already have quite a bit of experience in this. However, in the project market we noticed that it was desirable to also integrate a fast and reliable way of assembly into our system. From there, IntalCLIX was born." IntalCLIX is Intal's glazed frame principle. It consists of a prefab glazed aluminum frame equipped with an assembly spring system that can be installed simply, quickly and precisely.

Unburden contractors, shorten construction process

Visser: "By producing the aluminum facade elements as completely as possible in the factory, the contractor can build faster on site. We glaze the aluminum frames in the factory, adjust the hinges and add the mounting spring system. With IntalCLIX, a contractor is less dependent on an on-site assembly crew because you have already used that expertise in the factory." The ready-made facade elements can be hung directly into the facade on site (or incorporated into the modular facade elements at the contractor's factory). It enables contractors to significantly reduce construction time, and scaffoldless construction can take place. "So a big savings in time and costs," according to Visser.

Simply, quickly and securely wind and watertight

Thanks to the mounting spring system as part of IntalCLIX, both prefabricated and modular facades and façades on construction sites can be assembled simply, quickly and securely wind and watertight. "The system sits all around in the opening of the facade, so the frame can be easily clicked into it and secured. Truly click and ready! This allows us to achieve that speed. Because the façade is immediately wind and watertight, the finishing work can begin faster, which in turn benefits the lead time of the overall construction process," Visser continues.

High quality and durable

But there are other advantages: "By delivering the façade elements as completely as possible in a conditioned factory environment, you are not affected by weather conditions, which allows you to guarantee the quality of the products. In addition, the risk of breaking glass in a factory environment is much lower than on a construction site. As a result, failure costs will also decrease. IntalCLIX is also a sustainable and circular solution," Visser concludes. "When IntalCLIX is applied, fewer transport movements are required (both horizontal and vertical), which is beneficial in reducing CO2 emissions. Moreover, our aluminum window frames are made of circular aluminum and have a lifespan of at least 50 years. They are completely demountable: the window frames can be removed from the facade completely damage-free, allowing them to be recycled over and over again."