Innovation in bending: complex shapes brought to life

Brouwers Algemene Buigwerken (BAB) of Herentals is a leading Belgian company specializing in the bending of various metal profiles. With more than 30 years of experience in the industry, BAB provides customized solutions for construction, industry and interior applications. Owner Edsko Brouwer talks about his area of expertise.

BAB combines traditional craftsmanship with state-of-the-art computer-controlled technologies. With this, BAB's experts bend a wide range of profiles and materials such as stainless steel, aluminum and painted metals to the highest quality standards. BAB is active in a variety of projects, including cladding, balustrades, billboards and even aircraft components. The company is known for its flexibility, fast delivery times and cost efficiency. Its advanced Swiss-made bending machines make it possible to realize complex shapes such as S-curves, pointed arches and oval profiles with extreme precision.

Appropriate solutions for every demand

Says Brouwer, "We have worked on such well-known buildings as the Courthouse in Hasselt, the PMG building in Antwerp and the Port House of Antwerp, among others. For the church in Steenwijksmoer, we bent several window profiles." Brouwer has been in the business for more than 25 years and uses his expertise to provide a perfectly fitting solution for every project. After all, bent profiles are used in all sorts of sectors. From the automotive industry to aviation and shipbuilding, metalworking, stand construction and store fitting and even for interior applications. BAB's specialty? "Those are the more complex projects. And we are good at bending very thin materials. You see that more and more these days. Whatever the customer or architect wants: we can almost always bend it."

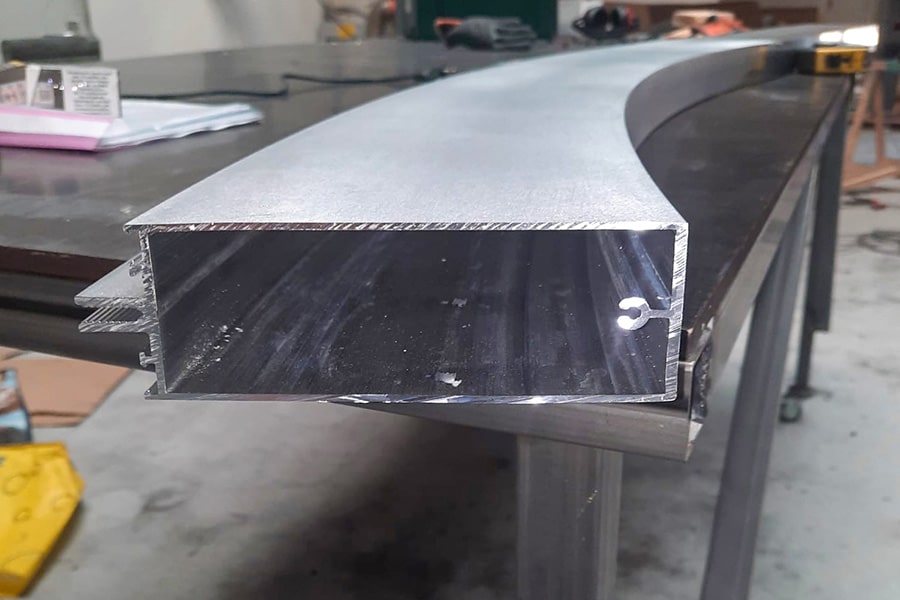

Curtain walls: a trade in itself

BAB's flagship products are the curtain wall profiles. These applications require extreme precision. "Curtain walls are challenging and special," Brouwer explains. "The wider the curtain wall, the more challenging it becomes. This requires a unique process that we have developed in-house. Our special technique ensures that the profile deforms as little as possible." This knowledge and know-how is transferred into other projects and profiles, such as glass clamp profiles and balustrade profiles.

Getting better and better

Brewer is always innovating and developing. "We want to get better and better. That's why we experiment with new processes and machines. You really have to have the technical know-how for that, because then you're one step ahead. Our trump card is that we always know how to bend something well. We just have that insight." The company updated its machinery two years ago with the latest machines and a pc400 control system, in order to deliver perfect rolled sections to customers. "Six months ago we also invested in a PBT35 wide with servo motors. This machine is more powerful, allowing us to roll larger profiles. This allows us to serve our customers even better."