Innovative dormer construction enables fast and safe renovation

15 residential blocks in 5 months, executed by one team

Comfortable, energy-efficient and future-proof living. That was the ambition of the Dalveen project in The Hague, which involved major maintenance, making 75 single-family homes in the De Venen neighborhood more sustainable and gas-free. Commissioned by ERA Contour, IJsselmonde Buitengevelisolatie provided the fifteen residential blocks with 5,000 m² of external facade insulation with mineral facade strips and decorative plaster, as well as 9,000 m² of Blitz steel facade scaffolding. “Most special in this project, however, was the dormer construction,” says director Bas Boere of IJsselmonde Buitengevelisolatie. “In cooperation with IJsselmonde Steigerbouw and Layher, we developed an innovative and mobile Layher Zeilregeldak XL dormer construction, which made it possible to safely carry out the roof work at a rate of one house per day. Regardless of the weather.”

The idea for the dormer construction came about in the spring of 2024, while making a test house. “This is a regular part of ERA Contour's project approach, with the aim of testing work and planning and optimizing them where possible,” says project manager Peter Vork. “But also to be able to offer a model home to all residents so that they can get a good understanding of the maintenance and home improvements.” The completion of the home was scheduled to take four weeks, but due to heavy rainfall, the work on the roof extended by several weeks. The roof work included, for example, the removal of the chimneys with flue pipes and the fireproofing of the house separating joints. “This required cutting open the bitumen roofs at these locations,” he says. “The roofs were then fitted with new insulating roof panels, which were glued in with care.”

Staying ahead of stagnation

Actual construction was scheduled for the first half of 2025. “A period in which rain and frost are no exception,” said ERA Contour's contractor Roland Zandstra. “In order to stay ahead of stagnation as a result of this, together with IJsselmonde Buitengevelisolatie, IJsselmonde Steigerbouw and Layher, we searched for an effective and economically efficient solution that would allow us to continue working even in bad weather conditions and stay ahead of rain and frost delays.” The joint brainstorming led to an innovative approach, covering the roof with a mobile Layher Zeilregeldak XL dormer construction, says Boere: “Thanks to this roofing structure, we were able to guarantee a throughput of one home per day, regardless of weather conditions.” This kept the construction train on steam, allowed IJsselmonde Buitengevelisolatie to start the application of the exterior wall insulation, mineral wall strips and decorative plaster on time, and the project was delivered exactly on schedule on July 23.

No unworkable days

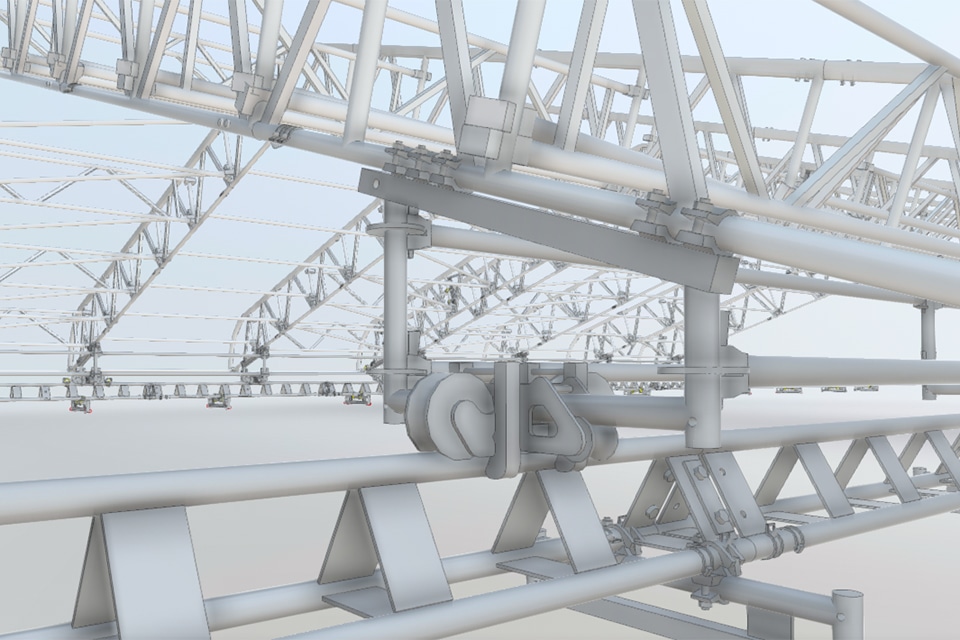

Layher's 9,000 m2 steel Layher Blitz facade scaffold served as the basis for applying the exterior facade insulation, mineral wall strips and decorative plaster. “By placing the movable Layher Zeilregeldak XL roofing structure on top of this, ERA Contour and its roofing partner benefited from an optimum in safety as well as efficiency,” said general manager Kevin Boere of IJsselmonde Buitengevelisolatie. “Unworkable days were no longer an issue.” The dormer construction was conceived, calculated and fully developed in collaboration with Layher. “Here, a very deliberate choice was made for a mobile construction over one house and with an overhang, so that everyone could work safely and dry and also to ensure financial feasibility.” The dormer construction rolled along one house each day, he says. “Once a block was completed, the entire structure was grabbed and lifted to the next building block using our own heavy-duty crane.”

“Layher was actively involved in advising and engineering the dormer construction,” emphasizes account manager Mike Tukker. “And we were also on standby with our knowledge during execution. We collaborated with IJsselmonde Buitengevelisolatie on the construction of the structure, so that it was perfectly suited for the roof and the work that was being carried out here. Moreover, we inventoried the working height and its impact on the maximum wind load, so that functionality and safety harmonized.”

Light construction

“At the base of the Layher Zeilregeldak XL roof cover construction is a kind of roller coaster rail, which is placed on top of the steel Layher Blitz facade scaffold,” explains project manager Glenn Hollemans of IJsselmonde Steigerbouw. “The construction itself consists of modular aluminum truss elements with keder profiles, in which the roof tarpaulin can be mounted very easily.” Combined with a mobile system, the lightweight construction can also be moved very easily, adds project manager Mark Speksnijder of IJsselmonde Buitengevelisolatie. “The mobile dormer construction is suitable for both ground-level and stacked houses up to four storeys high, with a flat (straight) facade and a flat or gently sloping roof.” Tukker: “Depending on the design and load, a maximum span of 32.5 meters is possible in a standard construction. With specific modifications, even larger spans are possible.” ❯

In project Dalveen in The Hague, two coupled roofing elements 7.5 meters wide were used to cover a complete house 15 meters wide. “By means of an overlap console, the connection between the two driving roofs was also watertight.”

Safety first

“The Layher Zeilregeldak XL dormer construction used is suitable for a maximum wind load of 10 Beaufort and a maximum snow load of 60 kg/m2,” says Tukker. “In project Dalveen, however, a maximum wind load of 8 Beaufort was calculated. IJsselmonde Buitengevelisolatie used a maximum wind load of 7 Beaufort for safety reasons, as well as a maximum snow load of 25 kg/m2.” The wind force was continuously monitored. Hollemans: “If the wind force was too high, we could easily slide the roof tarpaulins out of the structure, within an hour to two hours and with only two men. When the weather was stable, the tarpaulins could also be easily replaced, after which work could be resumed a short time later.”

Benefits in a nutshell

According to Tukker, a major advantage of the dormer construction is that the continuity of planning is guaranteed. “Contractors no longer have to take lost days into account, which allows for more competitive quotations. Moreover, scarce available personnel can be used super-efficiently.” Rain, snow and frost are no longer issues, eliminating a lot of stress, Zandstra and Vork add. “Towards summer, we have also noticed that even on very hot days it is pleasant to work under the roof structure. Engineers are no longer standing in the full sun, which makes work safer and more pleasant. Moreover, the bitumen roof is better protected, while the use of light tubes in the roof construction guarantees optimum visibility.” Not surprisingly, the possibilities of this innovative construction for various follow-up projects are now being discussed.

Heeft u vragen over dit artikel, project of product?

Neem dan rechtstreeks contact op met IJsselmonde.

Contact opnemen

Contact opnemen