100% modular and circular construction with pluggable installations

Responding to changes in housing

Construction is modernizing considerably. The enormous housing shortage, the shortage of skilled technicians, the limited space on our construction sites and the ambitious climate objectives demand new ways of thinking and working, with the emphasis on sustainability and efficiency. Prefab and modular construction plays into this optimally. By building residential and utility buildings together in the factory under the best climate and labor conditions, construction speed and quality are increased. Moreover, circular and remountable construction is possible. Thanks to Isolectra's GST18®, RST20® and Streda installation systems, installation techniques can also be included from now on. From electricity to data, from wall to floor and from HSB to CLT or concrete construction.

"Prefab construction and installation requires knowledge, innovativeness and cooperation," knows Jordi Blanker, Market Manager Residential at Isolectra. "But also for sophisticated logistics and products that follow the contractor's prefab manufacturing and construction process. We respond to this with a range of standard products that can be optimized at project and process level."

Development toward housing

Isolectra is the founder of prefabricated installation in the Netherlands. "We started as a trading company and gradually specialized in non-residential construction, aiming to create the most efficient construction and installation process possible in offices, hotels, kitchens, the retail market and even academic hospitals and operating rooms," says Blanker. "With all the developments in the market, we are now also well known in prefabricated and industrial housing construction, where there are specific challenges regarding sustainability, detachable construction, waste management, planning and circularity."

Leading in knowledge and technical applications

"Prefab is not just prefab," Blanker emphasizes. "Every demand, every process and every construction method is different." So how can you still standardize and remain flexible in that? "We know the market and understand the interests and needs of our clients. Moreover, we have all the technical knowledge to develop products and systems. We are familiar with the standards, laws and regulations and tailor our products exactly to the customer's desired construction method, building materials and processes. Regardless of whether these products are processed on-site at the construction site or off-site at the factory. We have the knowledge and the power to quickly come up with new prototypes and ideas and can implement a very specific supply process, whereby installations are prepared and/or labeled in advance. All with the goal of making a flawless installation as quickly and efficiently as possible."

Concrete, wood frame construction or CLT

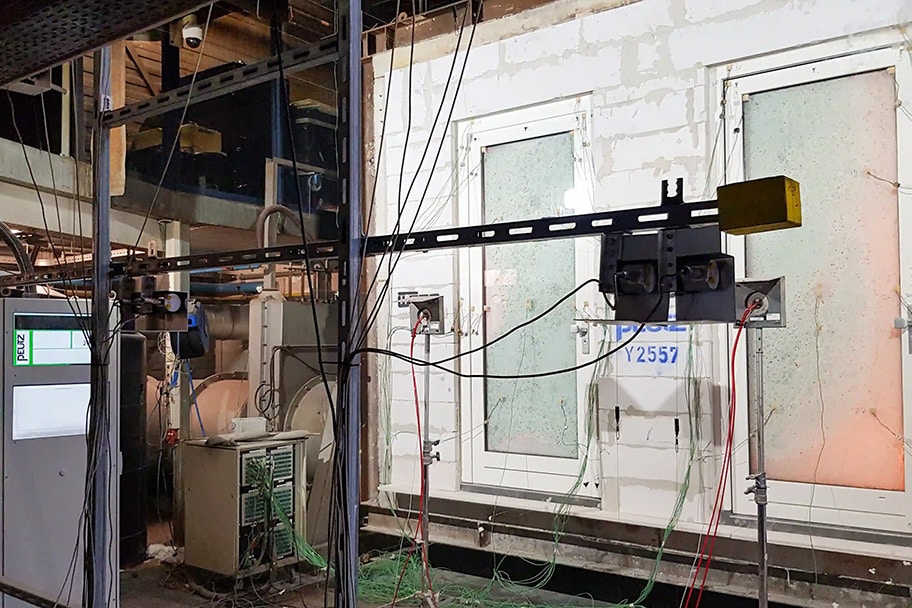

Depending on the construction method (concrete, wood frame or CLT), installers have a choice of the Wieland GST18® and RST20® systems from Isolectra. "Where GST18® ideally suited for dry environments, the RST20® cables and connectors specifically designed for wet construction," Blanker said. "The cables and connectors in this system are so robust and reliable that they are the only ones in the market certified to be cast directly, without conduits, into precast concrete walls and concrete floors. Because the Wieland GST18® and RST20® systems are designed and certified completely maintenance-free, they may also be used in non-accessible places."

Flexible residential installation with smart outlets

A nice prefab development according to Blanker is also Streda: a flexible and modern IoT-based home installation with smart outlets that can do much more than just transmit power. "A universal cable, standardized flush-mounted boxes and a portfolio of snap-in modules with diverse functions (socket, smoke detector, doorbell, lighting switch and Wi-Fi transmitter) combine to form an integrated and flexible home network that allows any kind of device to be connected at any location. From heat pumps to mechanical ventilation and solar panels, with live readouts of consumption per socket. A universal cable here ensures the transmission of power and high-speed data signals." Thanks to this "hybrid infrastructure," substantial reductions in materials are possible, thus connecting Isolectra to an important R (Reduce) strategy on the circularity ladder.

Integral concrete floor with data and electricity

An innovative solution with Streda, for example, was developed in collaboration with market leader in concrete floors VBI. "Instead of the traditional installation spider, we jointly devised an unconventional solution where the Streda residential installation is incorporated directly into the integral concrete floor," Blanker said. "This allows contractors and installers to benefit from data and electrical directly into the precast floor. But also from an integrated and flexible home network with extremely short lines."

Sustainable and circular

"What makes our systems unique is that we can install detachable and without construction site waste," concludes Blanker. "Any changes can be made easily, which extends the life of the systems considerably. Moreover, at the end of the building life or in the event of major changes, the pluggable technologies can be dismantled and - after an extensive testing and certification process - reused elsewhere, resulting in a circular building installation."