900,000 pounds of steel as basis for new ING headquarters

In Linden, many disciplines come together

Construction of Linden began in April. ING's new and climate-adaptive headquarters on Bijlmerdreef in Amsterdam will have a hybrid main bearing structure, for which Vic Obdam Staalbouw is engineering, producing and assembling approximately 900,000 kilograms of steel. In addition, the North Holland steel construction company is supplying the steel plates for the Comflor steel plate-concrete floors and is realizing the steel stairs and fencing in the headquarters, with the ‘social staircase’ receiving special attention.

Careful engineering

Vic Obdam Staalbouw was invited at an early stage by developing builder Dura Vermeer Bouw Midden West to submit an offer for the new building. “Following our price, our complete scope of supply was also decisive,” says Rick de Keijser, project manager at Vic Obdam Staalbouw. “In total, we produce and assemble 900 tons of steel for the main load-bearing structure, with the many steel-concrete connections requiring careful engineering and coordination with the relevant construction partners. In order to properly accommodate tolerances and adjustment possibilities of other disciplines, for example, adjustment space is included in the detailing. Moreover, we have supplied pouring facilities for the concrete, so that we can connect our steel correctly everywhere.”

Good and workable solution

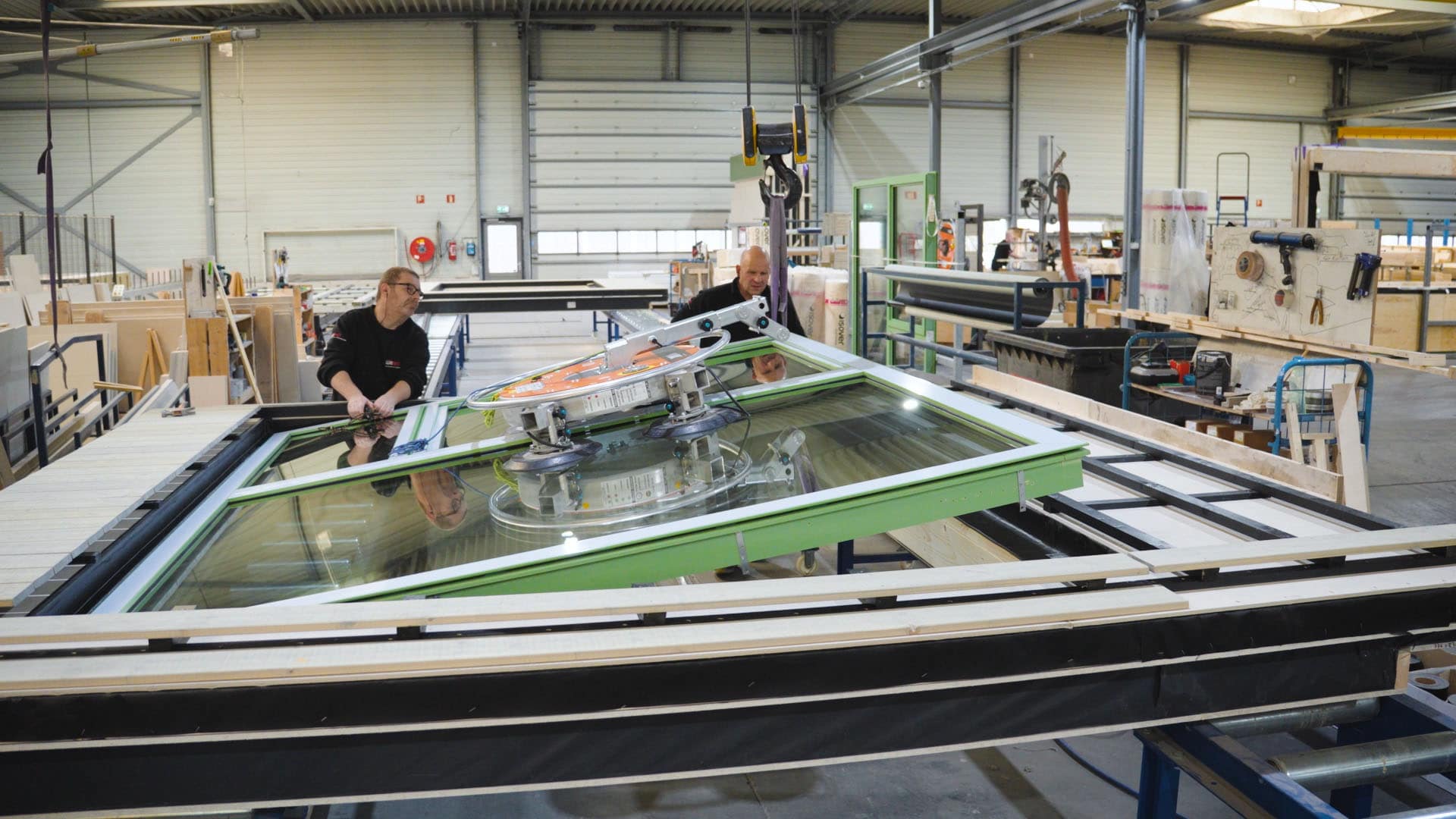

Following the concrete, De Keijser also mentions the interfaces with the installers and façade construction partners. “A huge number of disciplines come together in this project,” he says. As an example, he mentions the steel columns supporting part of the curtain wall, whose bronze coating must not be damaged during assembly work. “Together with the main structural engineer and Dura Vermeer Bouw Midden West, our engineer and constructor have engineered a good and workable solution for this. Here we not only use the main contractor's tower crane, but also our own Hoeflon C30 electric mini-crane.”

Various treatments

The steel structural members are given various treatments, such as a fire-resistant coating that swells to an insulating foam layer when exposed to heat, says De Keijser. “Steel structural parts such as the facade steel and stairs are also hot-dip galvanized and powder coated for additional corrosion protection and the desired color.”

‘Social staircase’

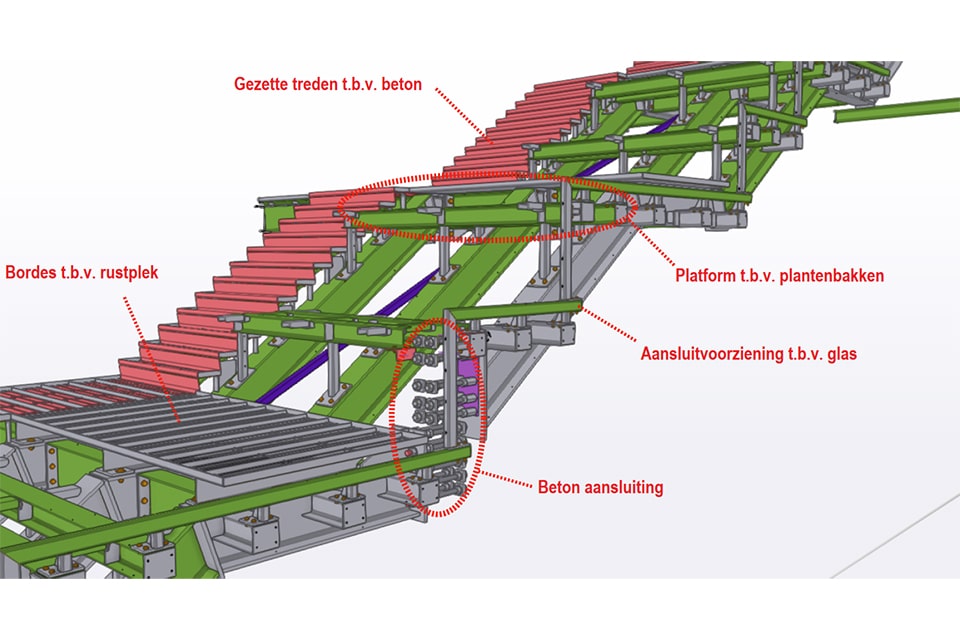

The project will feature standard stairs and railings as well as specials, concludes De Keijser, citing the ‘social staircase’ as an example. This imposing steel staircase, five meters wide and almost twenty meters long, spans two floors. “For this, Vic Obdam Staalbouw not only produced a main supporting structure of HE profiles, but also provides the containers in which the concrete steps are poured. In addition, we provide the facilities for the planters, seating platforms and glass balustrades.”

Heeft u vragen over dit artikel, project of product?

Neem dan rechtstreeks contact op met Vic Obdam Steel Construction B.V..

Contact opnemen

Contact opnemen