Less concrete, less steel, maximum flexibility

Environmentally friendly and lightweight floor scores high marks in utility construction projects

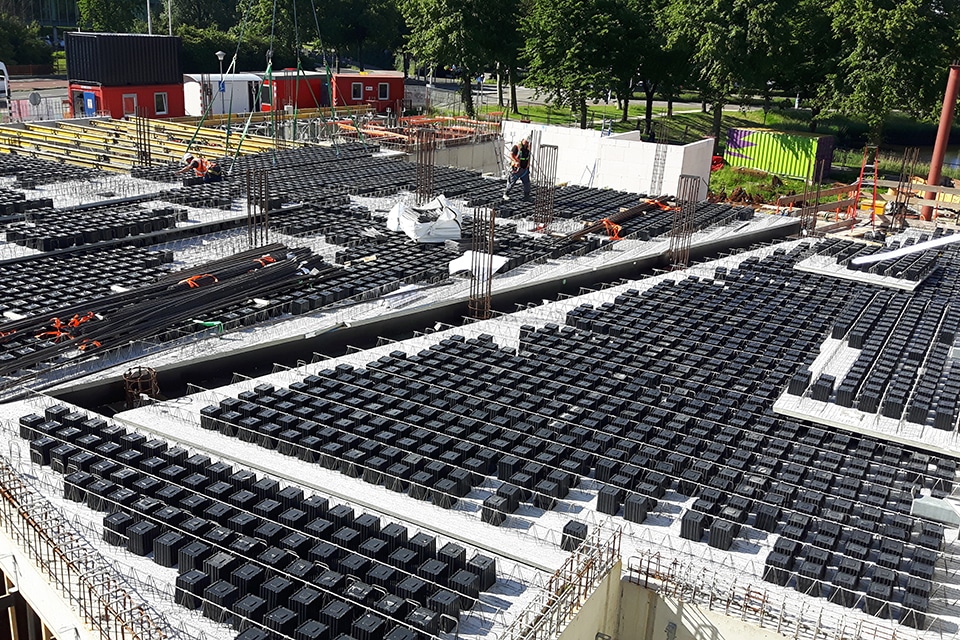

With Airdeck, De Hoop Pekso has been offering an innovative and lightweight floor for more than 12 years, which offers numerous advantages, especially in utility construction projects. Thanks to the use of special Airboxes, up to 15-20% can be saved on concrete. As a result, support structures and foundations can be made significantly lighter and larger spans of up to 12 m are possible. Because less concrete, less steel and fewer transport movements are required, the environment is less impacted. And because the Airdeck floor is designed as a flat floor, no beams or supporting walls are required. This ensures maximum layout freedom. The free layout makes the Airdeck floor extremely suitable for new construction projects in, for example, the healthcare sector.

The Airdeck floor has been doing well in utility construction projects for years. For example as an intermediate floor in parking garages and commercial buildings or as a storey floor in healthcare buildings, explains René Verstraete, Head of Sales Internal Service at De Hoop Pekso. "At the base of the floor is a precast concrete underlay of 6 to 7 cm, containing structural plate reinforcement and structural beams in a grid of 300×300 mm. Innovative Airboxes are inserted into this fully automatically. Special robots facilitate the process in our factory, positioning and integrating the Airboxes with unprecedented precision. Then the Airdeck floors enter the hardening chamber and not much later they are ready for transport."

Efficiency in concrete, rebar and time

The concrete-saving Airboxes are made of recycled plastic and available in five height sizes, depending on the desired span and required load. "Installation of the floor is easy because the elements can be lifted on the lattice girders," says Verstraete. "Then two people can place the elements on the temporary underpinning. On site, the coupling reinforcement and top reinforcement are placed. The reinforcement mesh can then be installed directly on the Airboxes and the pouring of the floor is done in the traditional way. This way of working saves both concrete, rebar and time." Thanks to their flat top and strong construction, the Airboxes can be safely walked on during construction.

Suitable for large spans

Jan Versteegen, construction consultant and partner at Pieters Bouwtechniek, emphasizes the suitability of lightweight storey floors for larger spans. "As the span increases, normally the floor thickness and weight also increase. Airdeck floors reduce this disadvantage by integrating Airboxes. These innovative elements create a thicker floor that maintains its strength and rigidity while reducing overall weight. The hollow design of the floor reduces the overall load, requiring less reinforcement compared to a solid floor of the same thickness." Based on the specified variable floor load in the Schedule of Requirements, Pieters Bouwtechniek invariably calculates the appropriate floor thickness and reinforcement. "The condition is that the specified load is equal to or higher than the minimum loads specified in the Eurocode that apply to a function. Despite using less material for the Airdeck floor, you can achieve the same strength and stiffness with a lighter floor."

Increased standards and detailing

The 2017 collapse of a lightweight floor at Eindhoven Airport cast a shadow over the reputation of lightweight floors. Both Versteegen and Verstraete refute this perception. Versteegen: "We have designed many such floors. Even as a result of the investigations after the accident in Eindhoven, we have not yet had to modify or reinforce a single floor. However, we did adjust our production process, based on the tightened detailing and calculation rules." Verstraete: "In recent years, the Airdeck floors have also continued to evolve. For example, we pour special cage reinforcement into the edges of the slabs, so that all structural requirements are met at once. We have also always been using traditional gravel concrete, which fully meets the increased structural safety standards. We find that this is very well received by the market and are increasingly being approached by reputable construction firms to assist in the preliminary process."

Detailed precision

Lightweight floors remain prominent in the industry, Versteegen states. "We include these floors in the various floor variants we consider for projects. For example, in utility construction projects with a column structure where flexibility in layout is required, this floor type is very suitable." Verstraete emphasizes that Airdeck floors have already been implemented over vast areas in the Netherlands. "A recent highlight project was Notting Hill in Hoofddorp, where over 1,300 m² of Airdeck floors were applied." Currently, De Hoop Pekso's involvement includes the new construction of expertise center and service building De Schakel in Nootdorp.

Heeft u vragen over dit artikel, project of product?

Neem dan rechtstreeks contact op met The Hope Pekso.

Contact opnemen

Contact opnemen