Stairs that inspire, innovate and take spaces to the next level ... for 25 years

Specialist performs everything in-house

Cornelis van Vlastuin and Dick Cluistra founded EeStairs 25 years ago. This specialist designs exceptional staircases that inspire, innovate and elevate spaces to a higher level, working with leading architects, interior designers and developers. Its creations are at the heart of many a project around the world and stand out for their iconic shapes, high-end materials and technical quality. EeStairs has more than a hundred employees. Martijn Cluistra has since taken over the role from his father Dick.

A staircase in the making

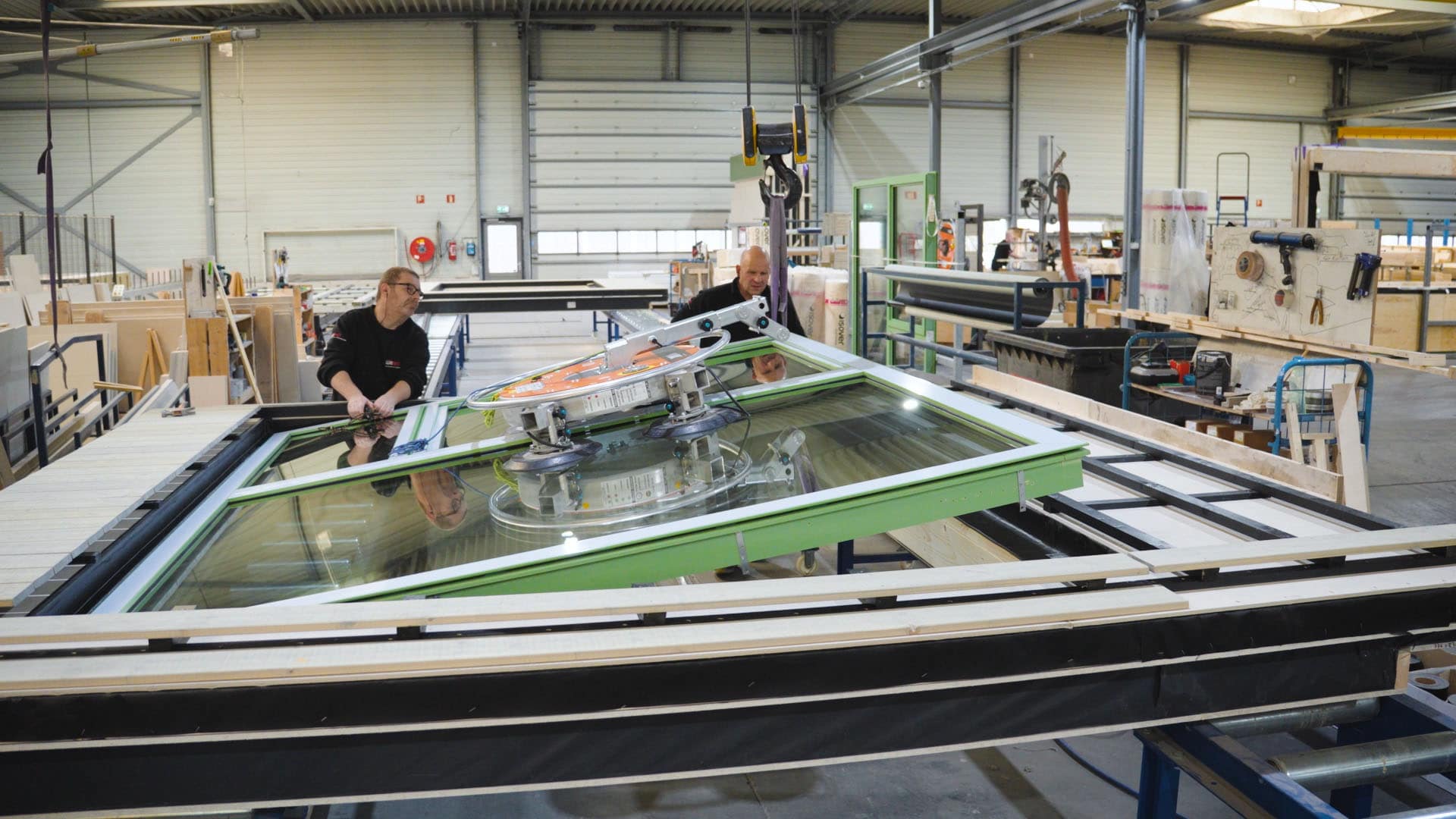

'Creating beauty between levels' - that may be taken quite literally at EeStairs. Innovators work at the company, using high-quality and modern equipment to design, engineer, manufacture, supply and install iconic stairs with outstanding architectural and craftsmanship quality. The team develops its own patented products, including the 1m2™ space-saving staircase, the NextGen™ office stair system, the Clips™ Quickfit Design Railings, the Cells™ laser-cut handrails, the GroovEe™ prefabricated glass balustrade, the TransParancy™ structural glass balustrade and the EeSoffit™ seamless soffits. For these products, customers can use the configurator to request quotes or place orders very efficiently and transparently. They enter dimensions and specifications and immediately see the price and delivery date, as well as receive a BIM model, eliminating the need to draw. The production process is also very efficient. Among other things, through the use of a welding robot.

"We also develop fully detailed staircase designs based on an architect's sketch or drawing," states founder and creative director Cornelis van Vlastuin. "Most of the stairs have a structure made of steel, which is fully shaped in our own production. For the finish of the treads, risers and the surface of balustrades or soffits, wood, wood veneer or even bamboo is used, which is also processed in-house. Steel is powder coated, wood is stained or specific surface textures are applied. We also install lighting systems and concealed sprinkler systems. Thanks to the man/woman joints, the stairs remain strong and after installation, only these seams are visible."

Even before the stairs are built, project managers determine how they will be transported. "They take into account the size of the stairs and how they go into a building, as well as the largest possible size for transport and the way to the construction site. On site, our installation teams reconstruct the stairs as they were originally made in production and finish them with wood, glass or another material. Attachment to the floor slab is done in collaboration with the contractors."

Attention to sustainability

EeStairs has more than 100 employees worldwide, three operational centers in Barneveld (Netherlands), Brantford (Ontario-Canada) and Eastborn (UK) and sales offices in Belgium, France and the US. "In everything we do, we pay great attention to sustainability," said Van Vlastuin. "Our headquarters and production facility in Barneveld was the first ever to receive a BREEAM Outstanding certificate. We installed six hundred solar panels, use wood waste as fuel for heating, and our employees can take advantage of a bicycle plan. We choose FSC-certified wood and recycled materials are used for our NextGen™ and GroovEe™. By choosing local suppliers, we significantly reduce transportation. 'Ee' stands for 'Exponent of Excellence,' which means that we strive for ever higher levels and want to be the best at what we do. We host architects and contractors to educate them and work with schools to train students. We want to encourage them to do something with engineering and hope to find skilled personnel more easily. This is important for our continued growth in the future."

Heeft u vragen over dit artikel, project of product?

Neem dan rechtstreeks contact op met EeStairs.

Contact opnemen

Contact opnemen