Pavilion as prototype. The future of building

DP6 architecture studio is responsible for the design of the State Pavilion at Floriade: The Natural Pavilion. According to Dick de Gunst, architectural director at DP6, this is a great example of what the future of building looks like. "We need to become more aware of our own potential," he said.

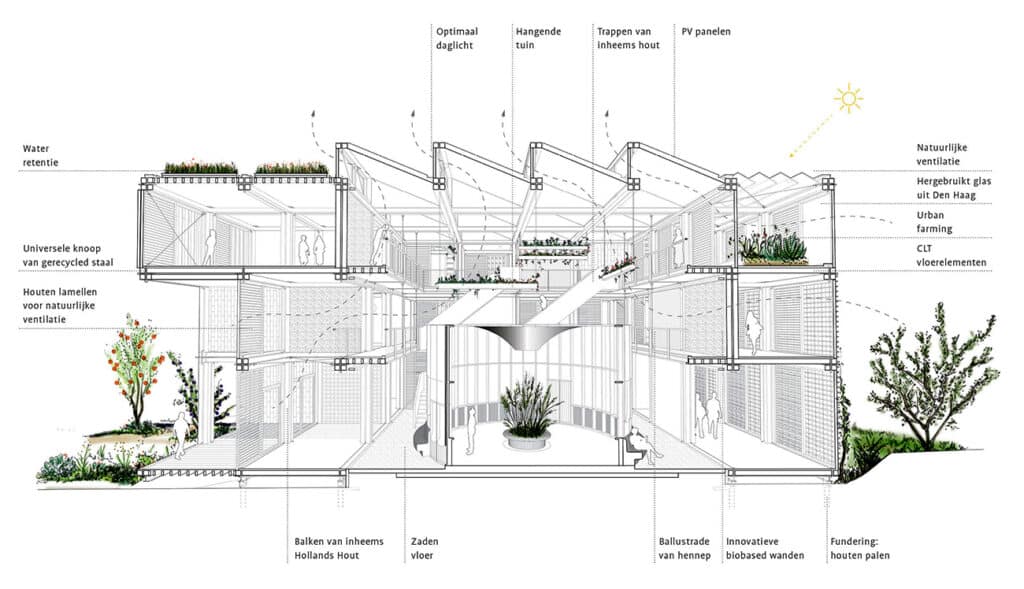

Noordereng Group is the client of DP6 and owner of the pavilion. This combination was already developing a wooden modular hotel in Ede when the Floriade issued a tender to design the State Pavilion. "The level of ambition was high. It had to be a completely biobased and circular building that, above all, could be built quickly," says De Gunst. "That was a challenge, but we were able to use it to our advantage right away. The pavilion has an exemplary function and we very much wanted to show how you can efficiently build with building materials available in the Netherlands. The fact that we could do it so quickly contributed to the pitch. The whole process from design to completion took nine months. So it can be done, because it's there." On April 14, the pavilion opened its doors. The building measures 25 by 25 meters and is ten meters high. It houses an exhibition showcasing many biobased applications of Dutch, sustainable building materials.

Impactful

The cooperation with Noordereng went very well, De Gunst said. "We have known each other for more than twenty years and know what we can gain from each other. Especially at such a construction speed, you have to be decisive as a team. We researched and invented a lot during the process. It's a different way of building after all."

Since both parties were already engaged in the process around modular construction, a lot of thinking and research had already been done. When the tender came for the pavilion, it was decided to make a "light" version of the hotel engineering. Circularity was an important requirement. The shell was made of Douglas fir from the forests of Ermelo. "Many people do not know that Staatsbosbeheer has a good wood production with sustainable, selective logging and that this wood is available for the Dutch market. From this wood, modules of 3.5 by 3.5 meters were made, which form the main supporting structure of the building. These modules are joined together with smart steel nodes and thus also easy to disassemble."

Once the shell was in place, it was time for the installation. Again, the builders used mostly biobased materials. Where that was not possible, circular materials were used. A good example is the reused glass that came from an office building in The Hague. The window frames were adapted accordingly. The starting point was thus the availability of the material, where in traditional construction the material is adapted to the design.

Vision

Sustainability is again reflected in the fact that the building uses very little energy. De Gunst says, "We made sure we had good temperature regulation and ventilation. The sun is generously allowed in for natural light and heat, but is also naturally kept out and ventilated away if it's too much. Windows open automatically when it gets too hot. That's also our vision for building: material is often added now to influence the climate, but you actually use a lot of energy with that."

The end result is a pavilion that feels natural. "There are air currents running through it. That may be healthier than airtight construction. We hope the pavilion will be embraced as a prototype and the principles behind it will be a wake-up call: if we want to build fast, let's do it in an efficient way with available materials. The Netherlands is used to being a trading company, while other countries have been using their own raw materials for much longer. We need to become more aware of our own potential."

- Client Noordereng Group

- Design DP6 architecture studio

- Contractors Post Bouw Urk, Lomans Totaalinstallateur, De Kuiper and Reimert Aderlaar, Ferross, HEKO and HB Oss

Project info

Bamboo decking and cladding

The Natural Pavilion features bamboo decking and cladding. "Bamboo is hard-wearing and ecologically sustainable. That makes it very suitable as a building material."

MOSO International BV develops and produces bamboo products for indoor and outdoor use. The product range includes flooring, outdoor products, boards and beams. "The bamboo stems are processed in China into, for example, decking boards, and we supply our products to sixty countries worldwide," says Paul Vriend, manager Benelux at MOSO.

For The Natural Pavilion, MOSO supplied 75 m² of terrace boards, including fasteners and four hundred lengths of substructure. This is distributed over two terraces in the building. In addition, the company supplied cladding to Zwarthout, which coated the facade panels with coal. These panels were also used on this project. "Bamboo as a building material has many advantages," says Vriend. "It is hard and therefore wear-resistant, falls into fire class B and is an environmentally sustainable and CO2-neutral material. It has a long lifespan; we give a 25-year warranty on our products. Botanically, bamboo is grass and not wood. Also, there is plenty of it available; the fast-growing plant is an endless resource, as it can be harvested without clearcutting. We use the Moso giant bamboo species from China."

MOSO has previously worked with The Natural Pavilion's architect, DP6. "Together, we have already completed several beautiful projects," he said.