Tauges specialist renovates to become even more sustainable business

New construction and expansion meet growing demand

Evers Specials is the largest bean sprout specialist in Europe. You know, those sprouts often used in oriental meals. Evers has a large-scale production process in which food safety is guaranteed. Doing business with respect for nature, environment and society are of great importance. We see this reflected in the renovation of the existing building in Nijmegen.

There will be a new building for a new packaging line, two additional loading docks and an expansion of refrigeration capacity. All this is to meet customer demand even better. Additional growth has also been taken into account here. "Downstairs it is about 420 m2 and upstairs about 920 m2, because the floor is partly built over the existing structure." Speaking is Joey Gademan, project manager at Aannemersbedrijf Hoes B.V. Horssen. It is the first time the contracting company has worked for Evers Specials, but it already has experience in the food industry.

Drawing versus reality

The building that was already there is now more than twenty years old. The employees of Aannemersbedrijf Hoes B.V. Horssen soon discovered that reality did not match the drawings of the building. Gademan: "Last year, before the construction period, we opened up the roof to measure everything again. We measured exactly where we needed to connect and then closed the roof again. The building is also not perpendicular, so we had to take that into account. This did make the project exciting for us, but fortunately we didn't encounter any other crazy things."

Smart installation

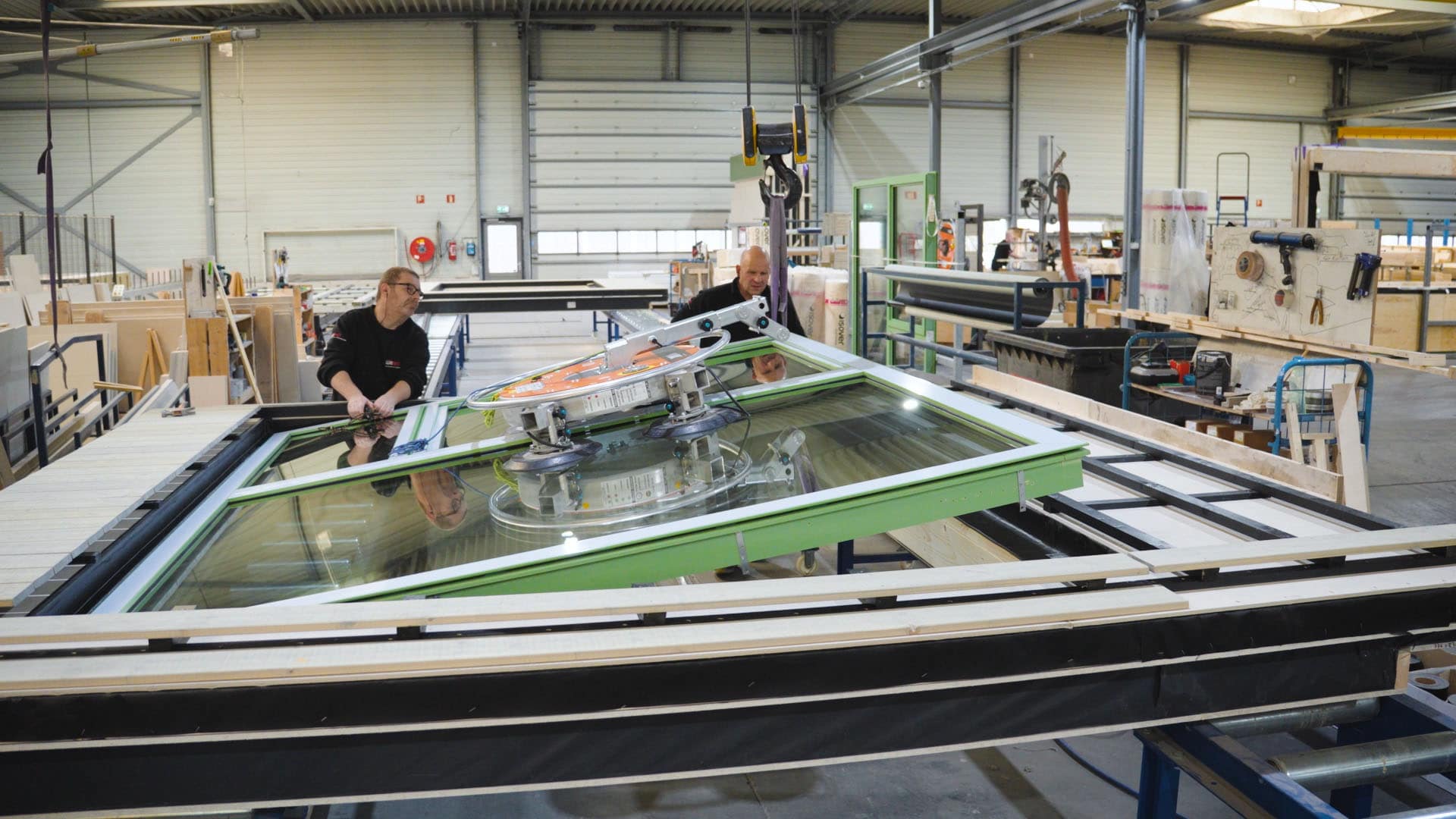

The new building will be fitted entirely with sandwich panels with a thickness of 160 mm. After all, a high insulation value is very important for the cooling of bean sprouts. In addition, a walkable installation ceiling was chosen in the building with a span of 27 meters. Gademan: "It is two meters high, and all the necessary installations were made on top of it as far as possible. Sustainability is very important. Solar panels will be installed on the roof and the energy within the building will be cleverly exchanged so that it is not lost. The new cooling that will be installed will be based on a natural refrigerant."

Multiple phases

Work is done in a construction team with bi-weekly meetings. The project is going well, according to Gademan. "A lot of choices have to be made and that is sometimes difficult for the client. We are happy to explain that. At the front, the loading pit still needs to be executed. There are temporary offices there now. Those will move in the future when the first phase is finished."

- Client Evers Specials B.V.

- Architect Boeijenjong Architects BNA

- Project Management Van Kessel & Janssen Bouwconsultancy B.V.

- Main contractor Construction company Hoes B.V. Horssen

- E-installer Nikkelen Elektrotechniek B.V.

- W installer Gebr. Janssen Beugen

- Cold plant Van Kempen Koudetechniek B.V.

- Construction period January 2021 - July 2022 BVO

- Building expansion 1.340 m2