One address, countless facade finishes

Leebo Intelligent Building Systems specializes in prefabricated facades and lightweight structures that enable better, faster and lighter construction. From design to realization. "With our insulated LeeboFrame® façade elements, LeeboFrame-Schock inside sandwich steel frame, LeeBond® aluminum composite panels, LeeBrick® brick stacking system and other intelligent building systems, we offer a total solution for a wide variety of façade types," says director KeesJan Nieuwenhuis. "With LeeStrip® we are also responding to the new building era, in which sustainability, detachability and circularity dominate."

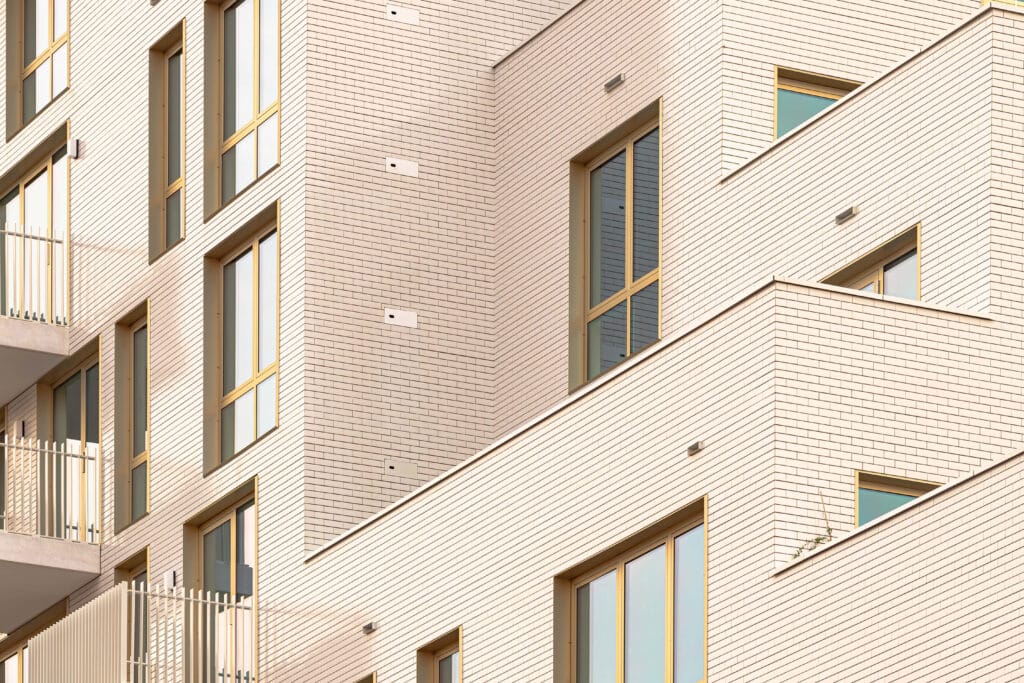

Porcelain Court in Delft

A great reference for this is Porseleinen Hof in Delft, where just under 60 km of LeeStrip® makes the "porcelain facades" fully demountable. "The shell of the residential tower and low-rise building is provided with concrete and HSB elements, on which we applied the aesthetic facade finish on behalf of ERA Contour," says Nieuwenhuis. "As many as 250,000 ceramic stone strips were installed in our LeeStrip® steel strips. The stone strips are glazed in matte white (2,370 m) and glossy white (2,366 m). In combination with the sophisticated surface distribution and under the influence of the sun, a special hue is created at any time of day, while additional tiles in blue offer an ode to Delft. A minimum joint of 4 mm was maintained between the stone strips, which provides an interesting shadow line and accommodates any tolerances in the building. The day edges, eaves and edges around the balconies and nesting boxes are finished with LeeBond aluminum composite."

Office building in De Lier

From Delft we move on to De Lier, where a new office building with an impressive facade was recently completed. "The office building is adjacent to an industrial hall clad in sandwich panels," says Nieuwenhuis. "Commissioned by De Vries en Verburg, we made the right connections to this. Both technically and aesthetically. The panels recur in a track around the office and are interspersed with wood and LeeBond® aluminum composite panels, which are mounted on a rear construction of LeeboFrame® cavity walls. In collaboration with Nedcam, special rounded corners were also created. The result is a chic facade that perfectly matches the desire for a healthy building with attention to light, nature and design."

Following the facade finish, Leebo also supplied LeeBond® aluminum composite panels for the ceiling of the canopy structure, which extends from the office across the industrial hall. The company also made wooden racks to go with the facades adjacent to the courtyard and in the same look as the office.

The House of Commons in Enschede

In Enschede, Leebo is now putting the finishing touches to Het Lagerhuis; a new and energy-producing residential building that generates more energy than it consumes. The design, use of materials and installations are focused on comfort, convenience and sustainability. For example, the building has been designed with circular materials and solar panels have been integrated into the facades. "Commissioned by Dura Vermeer, we manufacture and assemble 166 LeeboFrame® cavity walls, which are finished with a special combination of LeeBond® aluminum composite panels, solar panels and bamboo," says Nieuwenhuis. "This brings together appearance, sustainability and energy efficiency in a special way."

Dutch Masters in Amstelveen

Leebo has also started production of the prefabricated facade elements for project Hollandse Meesters in Amstelveen; a sustainable residential building with rental and owner-occupied apartments whose first facade elements will be assembled from May 2025. "Hollandse Meesters comprises approximately 14,000 m2 of facade area," says Nieuwenhuis. "For the finishing and commissioned by BAM Wonen, we are mounting a beautiful ceramic tile in eight colors on a rear construction of LeeboFrame® cavity leaves, in combination with our LeeBond® aluminum composite panels. All cavity trays will be produced this year, so that our production stays on steam and we can assemble our elements next year in a continuous construction flow."