Quick quoting, simple production

Wooden facade elements design, calculation and preparation in one BIM model

Faster, flawless and affordable construction with prefab wooden facade elements? VIANEN from Montfoort proves that it can be done! The leading manufacturer conquers the market with an online product generator, which from now on can also be used for calculations. The basis of the new method is the client's own BIM model, which prevents communication noise and ensures that dimensions, materials, techniques, properties and quantities always correspond perfectly. As a result, quality and efficiency come together nicely.

VIANEN has been the address for wooden window frames and facade elements for many years. "Since our establishment in 1961, we have had only one goal in mind, and that is to make well thought-out products," says director Oene Wassenaar. "We are constantly looking for ways to make our products and processes smarter, more beautiful and better. In the past two years, for example, we have been fully committed to the development of parametric models to speed up our internal processes. A first step taken in this regard is the parameterization of the time-intensive calculation process."

Faster pricing

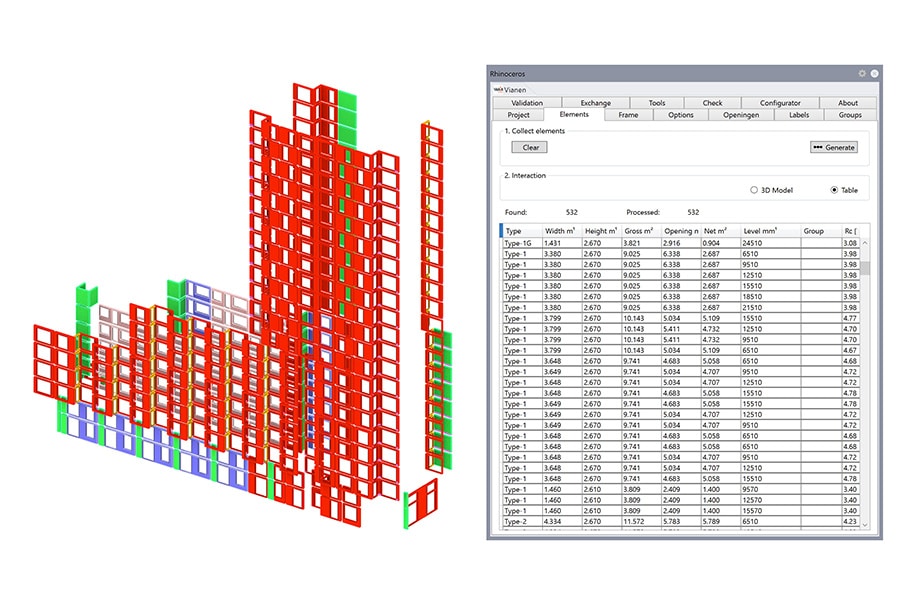

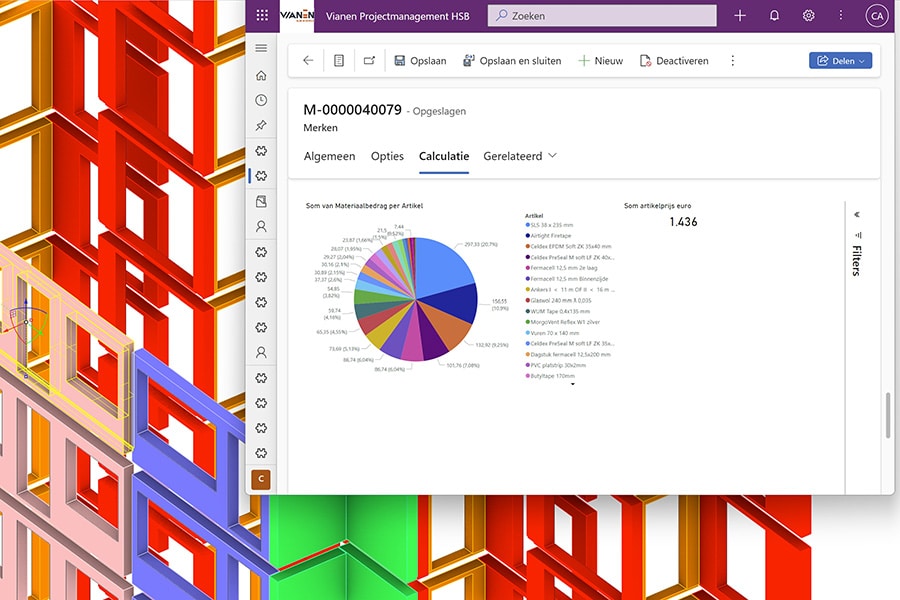

"We've been analyzing our customers' BIM models for a while now and see that their quality is getting better and better," Wassenaar emphasizes. "This is why we decided to use the BIM models from now on also for the quotation process of our prefab wooden façade elements. Quite a revolution, which saves our clients a lot of time. We can now digitally read and calculate our clients' BIM models in such a way that we can quickly extract a price from them. Simply by enriching the data from the model with our parametric product generator and digitally transferring it to our Microsoft Dynamics platform. This also allows us to simplify work preparation and production at a later stage through smart digital process integration."

Compare easily

Thanks to the new way of working, VIANEN sees even faster whether clients' BIM designs are suitable for its prefab method of working. Is a project technically and economically feasible? Do the elements fit into the production line? And can the desired quality be achieved? "In the past, the dimensions of facade elements and window frames were always pulled manually from a drawing," Wassenaar knows. "Then all the data was manually put into an estimation system, based on which the project price was worked out in a PDF quotation. The client had to manually compare the data from this quotation with his own model. A time-consuming and error-prone process, which is a thing of the past with our online product generator. Because we digitally convert the supplied BIM model into a transparent quotation and also return it digitally, including our additions, the client can easily overlay both models. This eliminates an enormous number of time-consuming and error-prone strokes from the preparation phase and makes the feasibility immediately clear. Moreover, we can return valuable data. When the BIM designs are converted into manufacturable VIANEN elements, we can easily add and visualize automatically generated insulation values (Rc values). The same applies to material data, which says something about the environmental performance (MPG) of a building. This simplifies the calculation of the MPG score."

Handy information card

To ensure that clients deliver constructionally and model-technically correct BIM models, VIANEN has developed a so-called information card. This describes what the BIM model must meet. Different degrees of model quality have also been applied to promote a fast calculation method. VIANEN's parametric software automatically recognizes the facade elements, after which the important properties are immediately generated and calculated. From element type classifications to width and height dimensions, net and gross surface areas and spar dimensions. Based on this, the HSB frame and insulation are automatically generated. "The calculator can easily indicate which options may be added to the element," says Chris Aerts of AplusV solutions in Ede, who developed the software application together with VIANEN. As an example, he mentions different types of plating and box fillings. "Once these characteristics are assigned, the model automatically generates all the parts. From the parametric model the material quantities in the desired unit then roll out, as well as other data important for the calculation."

Link with online calculation system

From the parametric model, an export is made of all quantities, after which all material prices and hours are determined. "This is done in an online calculation system that contains all items and hour formulas," Aerts said. "The data from the parametric model are linked to this, to then calculate all elements very accurately." The great advantage of the online environment is that the calculation department within VIANEN can learn from data from the past, says Wassenaar. "Because detailed information per element of all projects is stored, we can visualize cross-sections of important characteristics and relationships. For example, on resource consumption, prices, common options and cost developments. This provides solid support for reports and forecasts."

In control

Once the key figures for the quotation are ready, a quotation can be printed out from the online system. VIANEN also supplies an IFC model of the calculation. "This concerns an export from the parametric model, on the basis of which the client sees exactly which elements have been calculated, including the assigned element options. In short: thanks to our digital working method, large projects with numerous elements can be quoted quickly and we remain fully in control."

Heeft u vragen over dit artikel, project of product?

Neem dan rechtstreeks contact op met Vianen window frames.

Contact opnemen

Contact opnemen