New technology enables direct installation of plastic window frames in HSB elements

A new step in prefabrication

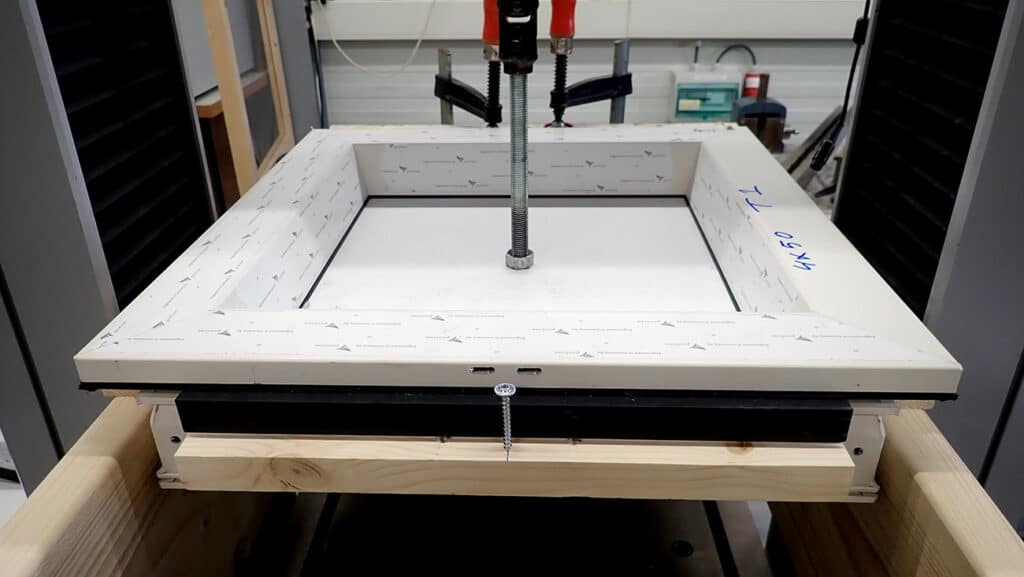

In high-rise projects, there are specific requirements regarding wind and water tightness. Among other things, window frames must be able to withstand extreme weather conditions without problems in order to prevent leaks, drafts and wood rot over time. "Vianen has been responding to this for several years with a prefabricated and facade-sealing HSB facade element, which gives wind and moisture no chance," says director Oene Wassenaar. "Currently, the aluminum and plastic window frames are still screwed into the elements from the inside by our facade builders, after which the glazing is applied. A labor-intensive and time-consuming process of sorting, selecting and fitting, which our new and certified eco-guarantee framework provides an effective solution to."

"The ecogarant framework was developed in cooperation with plastic window frame manufacturer Europrovyl, part of the VHZ Group, and involves a further development of our proven solution for wooden window frames," Wassenaar said. "At the basis of the system is a wooden cavity lath, which is integrated into the window frame by the plastic window manufacturer. Because the protected cavity lath construction already has an airtight tape, proper air sealing is immediately ensured."

Benefits for all stakeholders

What is unique about the eco-guarantee framework is that all stakeholders experience benefits, he says. "This puts the responsibility for glazing back on the plastic window frame manufacturer, where it belongs. After all, the way the glazing is mounted determines the strength and rigidity of the frame. Vianen remains responsible for the assembly in the HSB element and the air and water sealing; processes that we have completely under control. Because the ecogarantee framework significantly reduces the (logistical) operations in the production line, the risk of damage and/or errors also decreases while end users benefit from an excellent end product unchanged."

Also for the aluminum frame industry

The first projects using the ecogarant framework will soon be implemented. Wassenaar expects a lot from the technique, which is now also KOMO-certified. "A next step is to make the ecogarant framework available to the aluminum window frame industry as well, so that truly all market participants can benefit from its unique advantages."