Pluggable installation has the future

Pluggable in homes and existing construction

The German family-owned company WAGO is known to most people for the welding terminal, which can be found in many households. The company makes millions of these every day. However, WAGO is much bigger than that. The WAGO Group produces electrical connections, automation technology and interface electronics for households, industry, marine and lighting. At the beginning of this year, a new division was created: Building Technologies.

WAGO has been in the business of pluggable installation for 25 years, primarily within utility construction. This technology is now increasingly being used in residential construction. It was therefore a logical step for the company to merge its Building Automation and Pluggable Installation departments. The two fit nicely together within the new Building Technologies department, says Marcel Visser of WAGO. "Pluggable installation has made great strides in recent years because of the demand for sustainability and because of personnel shortages. You can quickly build sustainably and circularly with fewer failure costs. Installation is already taken into account in the design phase, making the method 70 to 80% faster than conventional installation. Especially at a time when we are short of hands and need to build faster, this is a godsend."

Prefab homes including installation

Until now, it was mainly hotels and student residences that were installed pluggable, because they are equal spaces that need to be ready quickly. In residential construction, conceptual construction and prefabricated production is now also on the rise, Visser continues. "Houses come completely ready from the factory with the electronics already in them. This is great for the developer and investor, but also for the installer. Who delivers a fully-fledged, certified installation in a short time."

WAGO not only produces and delivers the products, but also thinks along with clients, if possible already at the drawing level. According to Visser, it is important that the entire chain goes along with this innovative way of working. "We give the installer tips and elaborate drawings, but also enter into discussions with building owners and the structural contractor. It is imperative that the entire chain works well together."

100% maintenance-free

With pluggable installation, you get a modular system; the materials can also be reused at a later time. In the meantime, you don't have to worry about it. WAGO is the only supplier of pluggable installation that has a 100% maintenance-free certificate, certified by an independent party according to The British Standards. Visser: "The installations can then be mounted in places where you can't reach them later. That gives a nice feeling for the client and the installer."

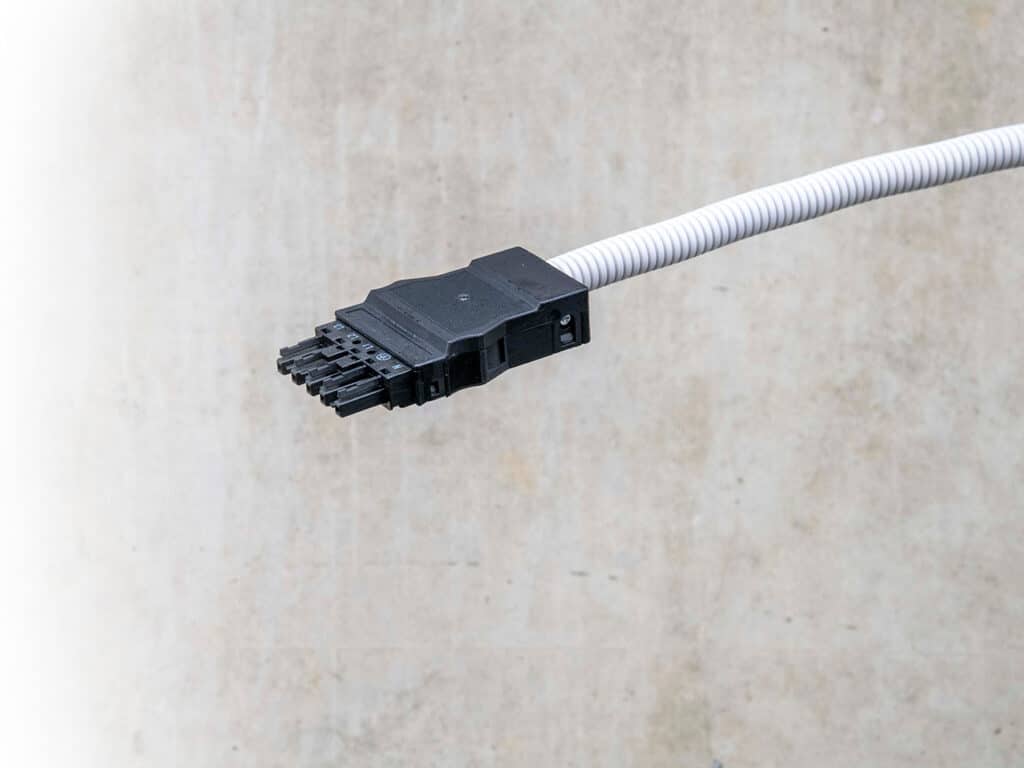

New tube adapter

Sometimes a building is modified or expanded. In order to combine conventional installations with pluggable installation, WAGO recently introduced a new tube adapter to the market. This hybrid solution allows you to reuse some of the materials. "The bridge from conventional to pluggable is thus easier to make. The first works with this tube adapter are now underway: a transformation project with 260 homes where the transition is being made from traditional installation tubes to pluggable," Visser said. Especially in non-residential construction, this product will be used, such as in hospitals and schools. There is often a repetitive nature to the work.