Building at lightning speed, with resident interest as starting point

The 333 homes in this extensive project are also improving both technically and aesthetically. To cause as little inconvenience as possible to the residents, Nijhuis Bouw B.V. is carrying out the work required for this at a rapid pace.

De Donken is a housing complex of housing corporation Mooiland and consists of the Viltmakersdonk, Tingietersdonk and Klingmakersdonk. Mooiland made the first plans for the preservation and improvement of these three residential buildings in 2019. Nijhuis was involved in this from the beginning. "As a chain partner, we carry out a number of projects with Mooiland each year," says Nijhuis project manager Richard Ligtenberg. "Over four hundred homes are planned for this year."

'Survey revealed draft and cold as biggest areas for improvement'

Lower energy costs, higher comfort

For De Donken in Apeldoorn, Nijhuis is responsible for the design and implementation. Nijhuis is also taking care of the complete resident supervision. "Increasing sustainability was an important precondition from the outset," says Ligtenberg. "The homes will be more energy efficient and go from energy label D to A. The interests of the residents are paramount here. Their energy costs must go down and their living comfort must go up. From the survey we conducted among the residents in the preliminary phase, drafts and cold came out as the biggest points for improvement." Aesthetically, the facades, roofs and stairwells are given a new, contemporary look. GAAV Architects worked out the entire design of De Donken in an integral 3D model.

35 kilometers of cladding

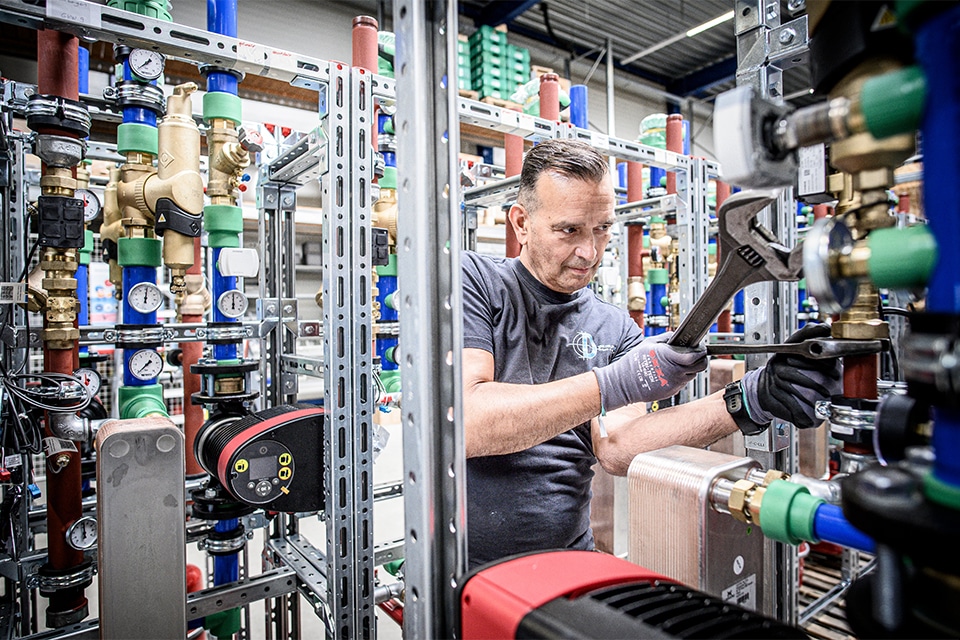

Construction began just after the 2020 construction period and will be carried out in two construction streams. Ligtenberg: "We started with the exterior stream. This consists mainly of installing the roof, cavity wall and floor insulation, fitting PV panels and installing fireproof front doors. In addition, some 35 kilometers of new cladding will go on the buildings." Eleven weeks after the start of the exterior flow, the second construction flow started. "These are the interior works," says Ligtenberg. "In the buildings, we renew the boiler room, we insulate the transmission lines and we replace the water line. In the homes, we are installing ventilation heat pumps. The exception is the upper floors, where we install solar water heaters. In addition, we perform painting and, upon request, we replace the kitchens, bathrooms and toilets."

'We include residents in the construction process as much as possible'

Reducing nuisances

When carrying out the work, the residents are taken into account as much as possible. With smart solutions, such as ready-made tile panels for the kitchens and sanitary areas, Nijhuis works quickly and efficiently. Moreover, noise pollution from chopping and breaking work is prevented. At the same time, the contractor is firmly committed to good resident guidance and communication. "We include the residents in the construction process as much as possible," says Ligtenberg. "We have to, to keep the train of work moving continuously. We are building at lightning speed in order to inconvenience the residents as briefly as possible. The challenge here is that the work is highly interdependent." To limit the number of transport movements in the neighborhood, Nijhuis set up a central construction site near De Donken. Here all materials are brought and prepared for processing on the construction site. Once a day, a truck with the necessary materials and products drives towards the homes.

Good cooperation

With ten homes per week and twelve days of lead time in the home, the pace of construction is good. The exterior flow is half completed and about sixty homes have been delivered. Ligtenberg: "The cooperation with Mooiland, as we are used to, is going extremely well. With the other parties we are getting better and better at working together. This is bearing fruit, both in terms of progress and resident satisfaction."

'3D model adds value in several areas'

Since October 2019, GAAV architectural engineers has been involved in the renovation of De Donken in Apeldoorn. The architectural firm, a regular partner of Nijhuis Bouw, modeled the entire project in Revit 3D and provided aesthetic guidance. GAAV also had an advisory role on flora and fauna. "The 3D information model added value in several areas," says GAAV's office manager Chris van der Maten. "The contractor used the model for the permit application and work preparation support, among other things. Our work also contributed to creating support among the residents." GAAV made color and material suggestions for the new situation at an early stage, which the residents were able to view in a test home. Using an interactive site, they were also able to make color choices. Van der Maten: "What I am especially proud of is that on this project we are doing our part on multiple levels to create fine, future-proof homes with respect for the environment."

Quick installation, minimal inconvenience

The major maintenance of De Donken in Apeldoorn includes the renewal of the sanitary rooms. The walls and floors of these will be covered with Keratop Tec-Board panels. The lightweight large format tiles with crack-bending capacity are being installed by Asschert tiling & total finishing. "We apply the Keratop Tec-Board elements in the bathrooms and toilet rooms," says Asschert project manager Wouter Spit. "In some homes, we also include the kitchens." The panels are cut to size on site and delivered to the homes in ready-made packages. This offers advantages for both the residents and the assembly crew. Spit: "The panels are easy and dry to assemble. And because they are cut to size outside the homes, we don't have to saw or cut in the homes. That saves a lot of dust and noise. Moreover, we are not bothering the residents as long. We need about 2.5 days per home. With traditional tiling, this is easily four to five days!" The pace of construction at De Donken is high. In order to keep up this pace with all parties, there was a lot of planning and mutual coordination in the preliminary stages. "That has paid off," concludes Spit. "Together, we are delivering ten homes a week."