Circular stripping lays sustainable foundation for Tinbergen Building

SMART RENOVATION ON CAMPUS

Before the renovation could begin, the Tinbergen Building first had to be thoroughly stripped. That task fell to Adex Groep, which specializes in demolition and asbestos removal. “It's a large and impressive project, but we're well on schedule,” says project manager Jan Loosman.

“We started with the elevator shafts,” says Loosman. “Part of the shaft was contaminated with asbestos. We sealed it off so that the rest of the shaft could be declared asbestos-free. This allowed us to put the elevators into use, which made internal logistics faster and easier. We were also able to increase efficiency in other areas. After validating the asbestos-containing interior walls, they could be removed in a single operation. That method proved to be both faster and safer.”

“After the asbestos removal and dismantling of fixtures on the upper floors, we started emptying the shell,” he says. “Ceilings, interior walls, and installations were removed step by step. At the same time, preparations began for the glass structure on top of the building.”

Circular thinking

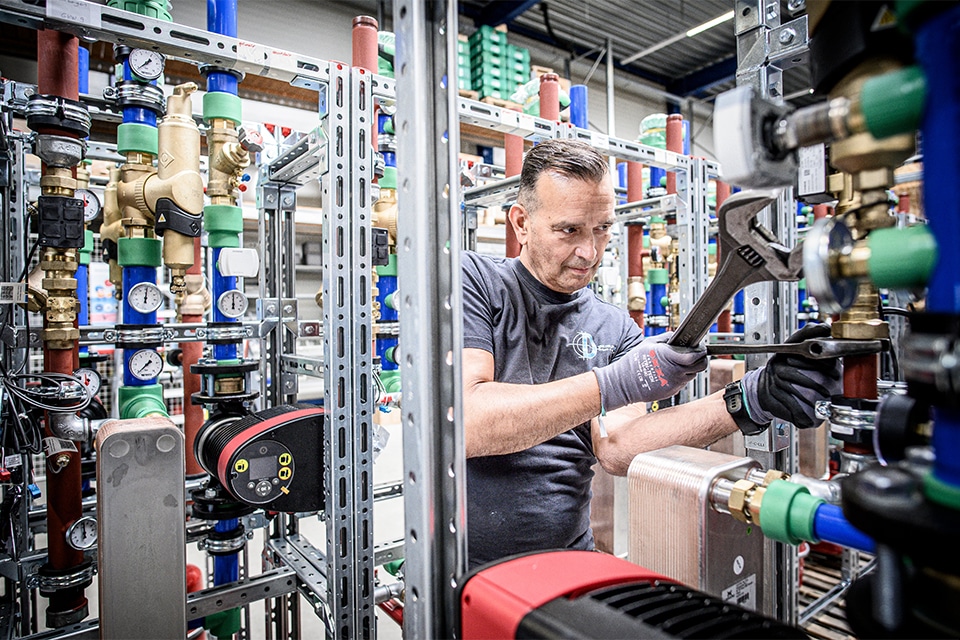

Sustainability is an integral part of the Adex Group's approach. “We drew up a circular report in advance,” explains Loosman. “In it, we always look at what we can reuse: air ducts, cable ducts, wood, and technical components. Much of this is given a second life in the Tinbergen Building, while the rest is used in our own sawmill, for example. We throw away as little as possible.”

Together in the heart of campus

Working in the middle of a university requires careful planning. “The campus will of course remain in use, so we have to be smart about logistics and noise,” says Loosman. “Most of our work takes place indoors, which works well. We haven't received any noise complaints yet. In a short period of time, we have accomplished a tremendous amount of work together with the builders. This is our first project with Heerkens van Bavel Bouw, and it is going smoothly. We already consider it a great achievement by the entire team.”