Digital solutions as part of an eco-circular approach

Tracking the life of a window: from design to reuse

Backed by the expertise of the Hydro Group, the SAPA brand is preparing a new generation of aluminum window frames and curtain walls. Digital solutions are crucial to understand these products in detail as well as to reuse them as part of an eco-circular approach. That is why Hydro has developed the My SAPA platform, which allows designers and carpenters to track the lifetime of a window, from design to reuse.

Digital technology and decarbonization

"Reducing the environmental impact of aluminum joinery and, more generally, reducing carbon emissions is clearly in our DNA," says Marc van den Nieuwenhof, account manager at SAPA Netherlands. This vision is reflected in the products, which are made from Hydro CIRCAL as standard; a 100% recycled aluminum containing 80 to 100% post-consumer aluminum. But also in future generations of products, which aim for 75% recycled material and 95% recyclability, while being easy to disassemble and reassemble thanks to the reduction of adhesives and silicones. "In this context, we cannot afford to overlook digitization. For us it is more than a tool, it is an accelerator of decarbonization and absolutely essential!"

My SAPA: a unique digital space

With the above ambition in mind, Hydro has developed My SAPA, a digital platform that is very intuitive to use and can be accessed for free with a personalized account. It allows designers and carpenters to track their joinery throughout its life, from design to reuse. "The goal is to maximize the value of the product at the end of its life," Van den Nieuwenhof emphasizes. "The more precise and complete data we can assign to a product during its lifetime, the greater the potential for reuse (or: recyclability if reuse is not possible). Digital technology makes it possible to upload as much information about the product as possible and retrieve it very easily, via a QR code assigned to each product."

The My Sapa platform brings together a number of tools intended for all parties involved in the project. From designer to user, joiner, et cetera, so everyone can find the key services and information they need:

- TechTIP is an engineering know-how platform that brings together all the documents an architectural or engineering firm needs when designing a building: plans, details, sections, certificates, approvals, upgrades, etc.

- SAPA3D is a 3D software package that designers can use to customize their object, with appropriate profiles and glazing, in IFC format, in REVIT or ARCHICAD, from the simplest to the most complex project.

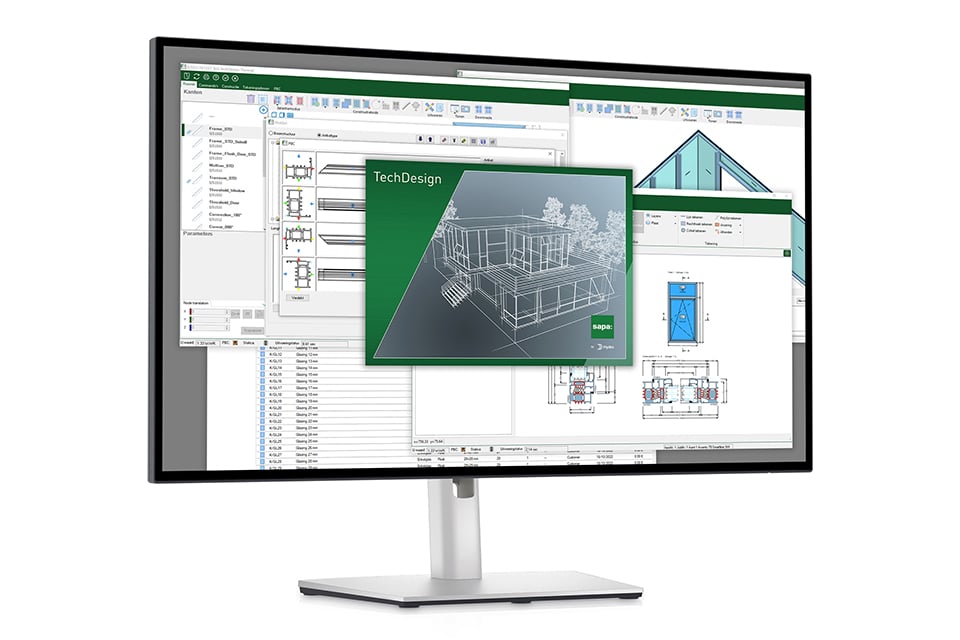

- TechDESIGN is a special tool for carpenters that allows them to estimate the cost of joinery, order the machines, issue machining orders, and so on.

Three value-added functions

My SAPA tools offer a number of benefits, the three most important of which are:

- Custom BIM objects created in SAPA3D can be exported to the architect's mock-up, with the latest dimensions and finishes of the frame. From profile to glass thickness, color, joints, et cetera, making the final rendering as realistic as possible.

- Produce an Environmental Product Declaration (EPD) of the relevant joinery that perfectly matches the choices made in terms of components, thickness, etc. Personalized, dynamic EPDs offer an advantage in terms of performance and, above all, transparency for carbon and environmental impact studies, which are increasingly required in projects.

- Once the frame is made, a QR code can be issued that provides a flash link to all of the frame's precise, detailed data. From technical data sheets to part numbers, quantities and end-of-life values for aluminum and glazing. In addition, the code can be used to track the window. Is it on order, in production, in transit or already installed? And what maintenance work and adjustments have been made?