310,000 pounds of aluminum for Rottemer Tunnel

From acoustic wall panels to anti-glare louvers

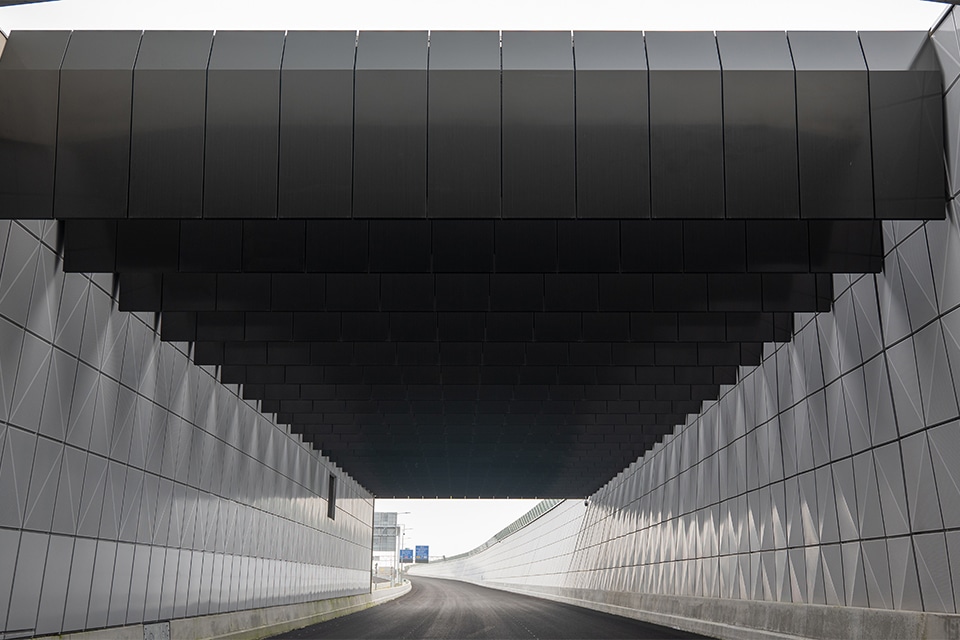

In October, the extended A16 Rotterdam opened; an 11-kilometer-long national highway between the A16/A20 at Terbregseplein and the A13 at Rotterdam The Hague Airport. In order to properly fit the new and energy-neutral route into the landscape, the Rottemerentunnel was constructed on the north side of Rotterdam. This tunnel has a length of 2,235 meters and runs under the Lage Bergse Bos and the river Rotte. The entrances are designed to be as transparent as possible, with glass sound barriers respecting the open character of the landscape. Aldowa acoustic pre-walls at the tunnel entrances also provide pleasant acoustics. But also for recognizability. In fact, the abstract pattern of the tunnel entrance walls recurs in all the structures of the A16 Rotterdam.

Project A16 Rotterdam was realized by De Groene Boog, a consortium of BESIX, Dura Vermeer, Van Oord, TBI (Mobilis, Croonwolter&dros), Rebel and John Laing. Following the acoustic pre-walls at the tunnel entrances, Aldowa designed, manufactured and assembled the ceiling slats of the new Rottemer Tunnel on behalf of this consortium. In addition, it realized the cladding for the fire-resistant cladding, which extends several dozen meters into the tunnel. “In total, our order includes no less than 310,000 kilograms of aluminum!” said project manager Martien Trouborst. “Biggest challenge in this project was to properly align aesthetics, fire resistance and acoustics,” he says. “But also to get from aesthetic design to final design and execution design in a short period of time. We held several scrum sessions with De Groene Boog and Quist Wintermans Architekten to get this right.”

Impression of a wybert

“At the base of the acoustic pre-walls at the tunnel entrances is a cold-bent magnelis steel frame,” Trouborst explains. “About 13,000 m² of acoustic insulation material was applied to this, achieving a road traffic noise reduction of up to 12 dB. The walls are finished with perforated aluminum panels in an abstract pattern that is not too busy but clearly recognizable. Rectangular panels were chosen in a diamond pattern and with a specific kink in the panels for depth, creating the impression of a wybert. A light gray color finish provides a neutral and calm atmosphere in this regard.”

Gradual transition

This atmosphere is continued in the cladding in the tunnel, while a dark gray-brown shade was chosen for the ceiling slats. “The 96 ceiling slats are located on the last approximately eighty meters of the tunnel and have a diamond shape in cross section,” Trouborst explains. “A nice detail here is that the top of the slats is always the same, but the bottom gets shorter and shorter. The anti-glare slats follow the rising line of the road, ensuring a gradual transition between the dark tunnel and the sunlight outside.”

Prefabricated produced

All the ramp walls were prefabricated and assembled at Aldowa's plant in Rotterdam, Trouborst explains. “Some 10,000 wall panels were required for both tunnel tours together, in which some 15,000 perforations were made per panel. The panels were assembled in elements 2.5 meters wide and 2.5 to 8.5 meters high, transported just-in-time to the construction site and then set with cranes. This allowed us tremendous speed in the assembly phase.”

Several months after completion, Trouborst looks back on the project with great satisfaction, combining technical complexity with a very beautiful end result!