Verbruggen Food Group moves to new DC: 60,000 sq. m. of construction in just thirteen months

The DC will have 55 loading docks, three office units and a 4,977-square-foot mezzanine. The total grocery supplier will occupy half of the DC itself; the remaining space will be leased. In the new DC, Verbruggen Food Group can continue to grow for the time being.

"Thirteen months for 60,000 m² of construction is a short time," says Roy Achterhoek, project manager of VDR Bouwgroep. "That's why we had to move fast. The architect made the design and VDR Bouwgroep made it executable. Fortunately, all partners have extensive experience in building DCs. Thanks to their cooperative attitude, we were able to get down to brass tacks quickly in the preparation phase. During execution, we ended up steering mainly on planning."

Additional transfer panels

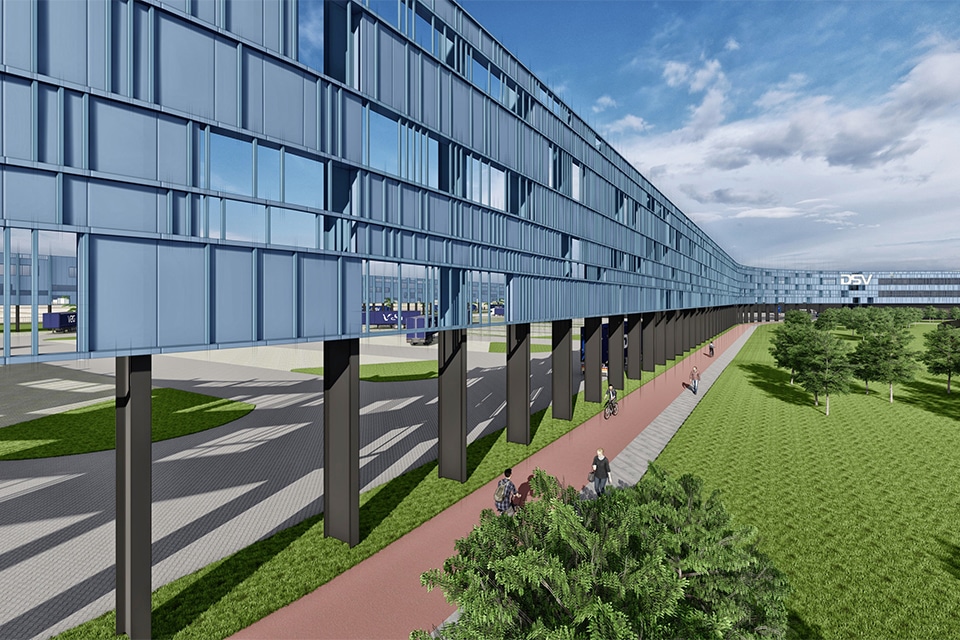

The appearance of the distribution center exceeds that of an average DC. The architect managed to create its own appearance by using sandwich panels with additional transfer panels in a variety of shapes. This has created a lively whole that seems to change constantly under the influence of sunlight.

Super flat floor

The height of over twelve meters requires a super-flat floor. After all, any unevenness in the floor can throw a reach truck at twelve meters out of balance considerably. VDR Bouwgroep outsourced this specialized work to VB Van Berlo. Achterhoek: "In shifts of 2,200 m², they poured a floor of 60,000 m² that meets the highest standard."

Environmental certification BREEAM 'Very Good'

The client is going up for a BREEAM 'Very Good' certification. For VDR Bouwgroep, this manifests itself in a series of environmentally friendly measures. For example, the heating is regulated with air and heat pumps, the roof is made suitable for solar panels, the number of traffic movements remains limited and only certified building materials are used. "We have a lot of experience in BREEAM construction," says Achterhoek. "An externally hired expert keeps all parties on their toes so that the certificate is definitely achieved."

Prepared for the future

With its NEXTERIA formula, VDR Bouwgroep specializes in circular construction. Achterhoek: "It is not a requirement now. Still, we bolted the steel structure so that the steel can be used relatively easily for other purposes in the future. The building is also all-electric; by 2022 it can be self-sufficient."

Construction Info

Client

Daytona Development bv, Burgerveen

Architect

Janssen Wuts Architects, Baarlo

Contractor

VDR Construction Group, Deventer

Construction period

February 2020 - March 2021

'Thinking along from the first moment, that works best'

To discuss the steel structure for distribution center Laarakker, IQstaal sat down with VDR Bouwgroep at an early stage. "Actually, that is the most efficient way of working together," thinks Bart Snoek, project leader at IQstaal. "Then we can use our know-how and think about the best approach from the very first moment."

For DC Laarakker, IQstaal provided the design and engineering, execution and assembly of the complete steel structure. It also supplied the stairs and fences for inside and outside, assembled the precast walls for outside and laid the hollow-core slabs for the mezzanine floor. "It was an extensive job," Snoek looks back. "And the execution time was short. We completed the above work in 15 weeks. But the preparations were excellent and the lines of communication were short, so the execution ran like clockwork."

The right flow through powerful collaboration

All aluminum facade elements for distribution center Laarakker were manufactured, delivered and assembled by Intal. With 2,000 m² of curtain wall, this was image-defining for the building.

The profile system used was developed within Intal and is also the only system Intal uses. "That does make us special," says project manager Robbert de Nijs. "We are the only facade builder with our own profile system. The curtain wall is made of our IT55 profile with a box depth of 175 mm. The standard IT77 profile was used for the window frames. The window, door and frame profiles have been further developed for years. They have developed into high-quality products and I expect that this development will never stop."

Precise tuning

When assembling the profiles, Intal closely followed VDR Construction Group's three construction phases. It inquired in advance about the pace, the disciplines scheduled before and after its assembly work, and the quantity in which the profiles could best be delivered. De Nijs: "That resulted in a delivery per week, in which we processed the delivery in five days. This created a continuous material flow with minimal need for storage space."

A well-oiled machine

"We did have start-up problems for a while," De Nijs acknowledges. "That was when we got to know VDR Bouwgroep as a party that wanted to find the best solution with us. Everything was negotiable. After that, the work went like a well-oiled machine. The last windows have now been installed."

All-rounder in painting

The painting work in Laarakker distribution center is broad and diverse. Meuleman Schilderwerken plasters the interior walls of the offices with fiberglass, provides part of the window frames with fire-resistant glass, glazes and paints the interior door frames, paints beech stair treads, coves and baseboards, paints the walls and supplies and assembles the sliding glass counter.

VDR Bouw is a regular client for Meuleman Schilderwerken. "Then you know what you have in common," says Fedor Meuleman, director/owner of Meuleman Schilderwerken. "Because of our long-term relationship, the atmosphere and cooperation at work are excellent."

Wide working area

Now Meuleman Painting is active in non-residential construction, but its scope of work is broad. "Call us an all-rounder. We also perform renovation work and residential construction projects. Our qualified professionals paint, set glass and wallpaper in the broadest sense of the word."

Standard and custom finishes make rooms ready for use

Of the three halls at DC Laarakker, Verbruggen Food Group will occupy one; the other two will be leased. Donec Afbouw prepares all spaces for use.

In the rental halls, Donec Afbouw installs partition walls, window frames, system ceilings and window sills. With paneling and plastering they make the rooms nice and smooth. In the hall for Verbruggen Food Group, the requirements are more specific and Donec Afbouw performs more custom work. "The vast majority of the work here is the same," says Tim van Berkum, project manager of Donec Afbouw. "In addition, glass walls are installed, for which we install the overhead fixtures. We are installing the ceiling in two colors so that the building will have a typical Verbruggen look. The work description here is more detailed."

With execution, things are going smoothly. "We've been working with VDR for a number of years and always meet the same people on jobs. We know each other by now and have something for each other. That makes for a good atmosphere."