From garbage dump to logistics paradise

On December 15, Van der Heijden bouw en ontwikkeling delivered phase 1 of this project to client Prologis. A distribution center to the highest standard for sustainability and with employee welfare at the forefront. And also on a brownfield site that previously served as a landfill. How unique that is? When we tell you that this is one of the first logistics projects in the Netherlands to be nominated for Well Building Gold and BREEAM-NL Outstanding certification, that says it all.

An eye for people and the environment was an important part of Prologis' assignment to Van der Heijden. The developer and provider of logistics real estate - one of the world's leading - is committed to sustainability and high quality in everything it does. So a project that combines awareness, well-being and a redevelopment like this is not for everyone. That the developer chose Van der Heijden is due in part to the drive, decisiveness and inventiveness for which the construction company is known. Jeroen van Beuningen, project manager at Van der Heijden, says: "The award was based on our transparent cost structure, commitment and resourcefulness."

From dirty to super clean

Greenfield sites, or previously unused land, are becoming increasingly scarce. Therefore, in the context of future-oriented land and building use, building on brownfield is an attractive alternative. But not an easy task. Especially not when the previous destination was a landfill, and the new one a highly sustainable and healthy logistics center. "That requires a good team of people with the right specific knowledge and experience. And a lot of precision in execution and careful adherence to procedures and work plans," Van Beuningen said.

The best working environment

Rarely in warehousing is so much attention paid to employee well-being as here. Prologis Park Eindhoven DC4 has a top-notch climate. With constant climate monitoring, cooling and filters that guarantee a continuous flow of clean air. But enough daylight and proper working lighting have also been considered. "In many warehouses there is hardly any daylight. Here we incorporated a complete skylight, supplemented with additional artificial light. Because when I work in a building, as a human being I need light," Van Beuningen says aptly. A people-oriented conditioned project, in other words. And thus a worthy candidate for the Well Building Gold certificate.

Sustainable dream location

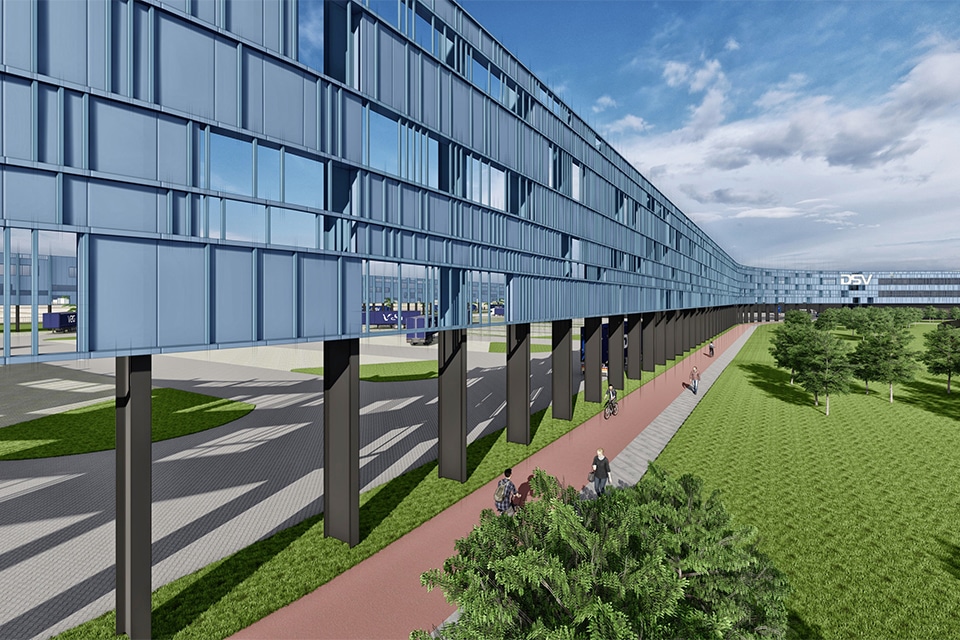

With the nomination for BREEAM-NL Outstanding, the developer and builder are going for the highest possible recognition in the field of sustainability. If you combine sustainability with knowledge and ingenuity, you end up with liveability. And thus a dream workplace for every logistics employee. An example? The garden plan. Imagine a park with walking paths and fruit-bearing trees where you eat your lunch at noon. With rich native planting, tailored to the Dutch climate. And beautifully integrated solar panels on the roof of the bike shed.

Smart solutions

Van der Heijden himself is especially proud of the conscious and practical solution for the main entrance. "We combine sustainability with functionality," says Van Beuningen. "In fact, the special solar canopy also serves as a closed and dry main entrance. This design allowed more solar panels to be installed and it also looks attractive. After all, sustainability is best seen."

Building can be different

A special project like this shows exactly what Van der Heijden stands for: top quality with a good level of finish. With smart, progressive and creative solutions in challenging situations, a decisive approach and good site management. So that overview and peace prevail. And careful execution in which agreements are kept and schedules are met, even in difficult times. In short: a project to be proud of. Or, in the words of Van Beuningen: "Quality is a rock-solid promise, not an option."

Project info

'Nice piece of customization'

After DC1, DC2 and DC3, Hermans Techniglaz was also involved in Prologis' ultramodern, sustainable DC4 in Eindhoven. For the canopy above the entrance to this distribution center, Hermans Techniglaz realized the custom-made solar panels, including the complete glazing system.

"The system consists of 144 Powerglaz semi-transparent solar panels," explains Rik van Ogtrop of Hermans Techniglaz. "These are custom-made solar panels constructed from two layers of thermally reinforced glass with laminated solar cells in between. Of these panels, we took care of the consultancy, engineering, delivery and assembly. With our years of experience in custom solar panels and daylighting solutions, we know exactly what is involved. For example, the steel and flashing required requires close coordination with the steel supplier and contractor. And then there's the electrics. We made the string plan and laid the cables from the panels to the inverter in the technical room. We also took care of the connection and commissioning. We look back on a nice piece of custom work that we accomplished in good cooperation with the contractor and other parties involved."

Project info

Engineering firm takes engineering of foundation, pile plan and steel structure

at his expense

Only when all construction partners are on the same page can the successful implementation and elaboration of a project be guaranteed. Main contractors must surround themselves with reliable partners. For example, Van der Heijden bouw en ontwikkeling involved the experienced engineering firm Verhoeven-Leenders as main structural engineer in the construction team for Prologis DC 4 in Eindhoven.

"We first worked out the foundation and pile plan. Since this building came on a former landfill site, there was intensive contact with Vroom Funderingstechnieken during engineering to arrive at the right pile choice," says project manager Patrick van Asseldonk. "The tight schedule only made this project more challenging. We also took on the engineering of the steel structures for the offices. The structures for the halls were worked out by the steel builder himself and checked by us. In February 2020, we submitted the first pieces for the foundation and pile plan. Thanks to close consultation with the municipality and smooth processing of the file, we were able to start the piling work less than 2.5 weeks later."