Finger on the pulse at construction pit NACH

Because the construction site is located in a densely built-up and vulnerable urban area, a comprehensive environmental risk analysis was essential. After all, next to the tub on the south side are the A10 motorway and the future construction site for Zuidas DOK, and on the east side is the Parnassusweg with tramway, which comes from an underpass under the A10. On the north side is the temporary courthouse. Moreover, Parnassusweg in particular is full of cables and (large diameter) pipes for gas and water. Reasons enough for an extensive risk analysis beforehand and monitoring during the construction of the two-layer construction pit.

For this task, Bouwbedrijf De Nijs, the builder of the tub, approached CRUX Engineering, a leading consulting firm with extensive experience in the field of geotechnical engineering, geohydrology and environmental influence in complex urban areas. Guido Meinhardt, Senior Specialist/Partner at CRUX: "If environmental aspects play a major role, as in the case of NACH, we can provide a complete risk analysis. We also ensure that monitoring is done at the right time and place. If you get that right, you can construct a deep construction pit and foundations in a controlled manner in almost any environment without damage to the adjacent properties."

Sonic vibration

The 9-meter-deep cofferdam was designed with sheet pile walls in which pre-tensioned anchors ensured the stability of the wall all around. An important factor was the requirement of the municipality that no (metal) anchors should remain in the ground. Meinhardt: "Props were out of the question, the cofferdam was too big and they can hinder the (concrete) work considerably. We therefore designed a construction pit with grout anchors, whose grout body is crushed by sonic vibrations when the anchors are pulled and the entire tube including the drill head is removed. Any future projects (foundations and tubs) thus have no obstacles." The anchors are prestressed to prevent elongation and thus deformations in the soil behind the wall and, in addition, hollow (emptied) to allow grout to be applied during sonic vibrating pulling and limit settlement due to volume loss.

'We make sure monitoring happens at the right time and place'

Plaxis

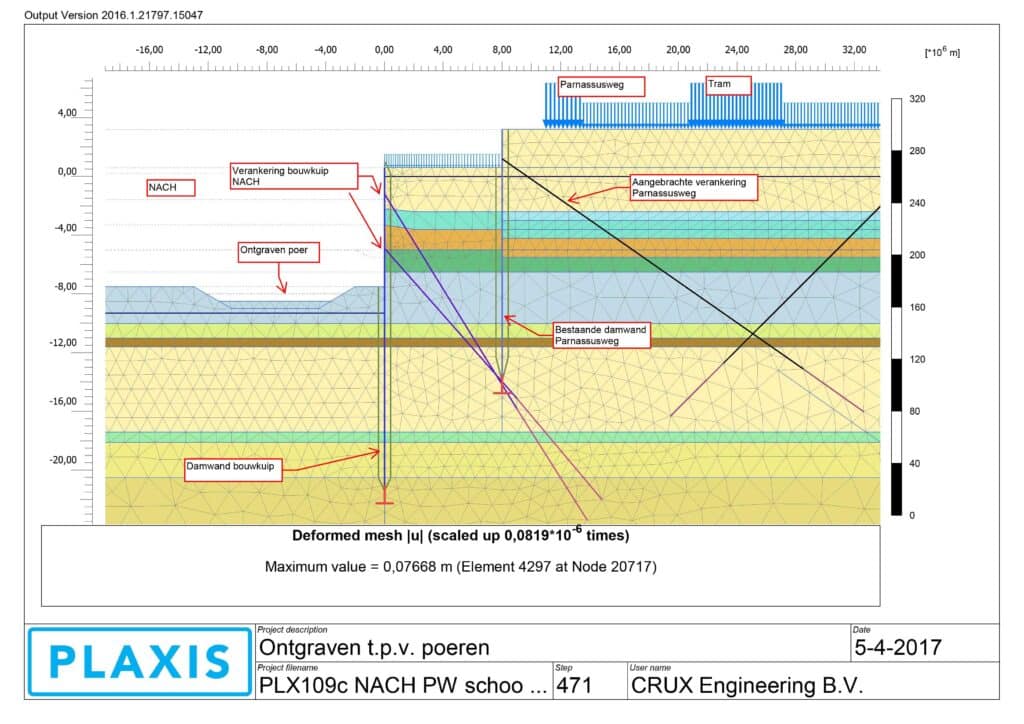

With a large construction pit in a sensitive area, monitoring of the construction pit wall, adjacent buildings, surrounding infrastructure and cables and pipelines plays a major role. Jefta Bouma, Senior Advisor Geotechnical Engineering at CRUX: "The design principles were clear, but there is always a small chance of deviations. Using design program Plaxis, the various permissible vertical and horizontal deformations were calculated and translated into a monitoring plan. For example, we fitted the sheet pile walls with inclinometers to monitor the horizontal deformations. In front of the A10, measuring studs were installed on the slope; if exceedances of safe values occur there, you only start taking measurements on the roadway that has to be closed off for this. That fortunately did not happen."

Being able to switch quickly

Thus, proactive monitoring was applied to every relevant component in the vicinity of the construction pit. Meinhardt: "So that also applies to the cables and pipes. Risk profiles are drawn up with the managers thereof, what is permissible is determined and any temporary decommissioning proposed. By approaching the environment in this way and then monitoring it, you give the construction activities measurable ground rules in advance. If things do go differently than you have calculated, you can move quickly because you have already inventoried in advance the possible measures that can be taken for the various exceedances."