Impressive steel creations for Scheveningen control center

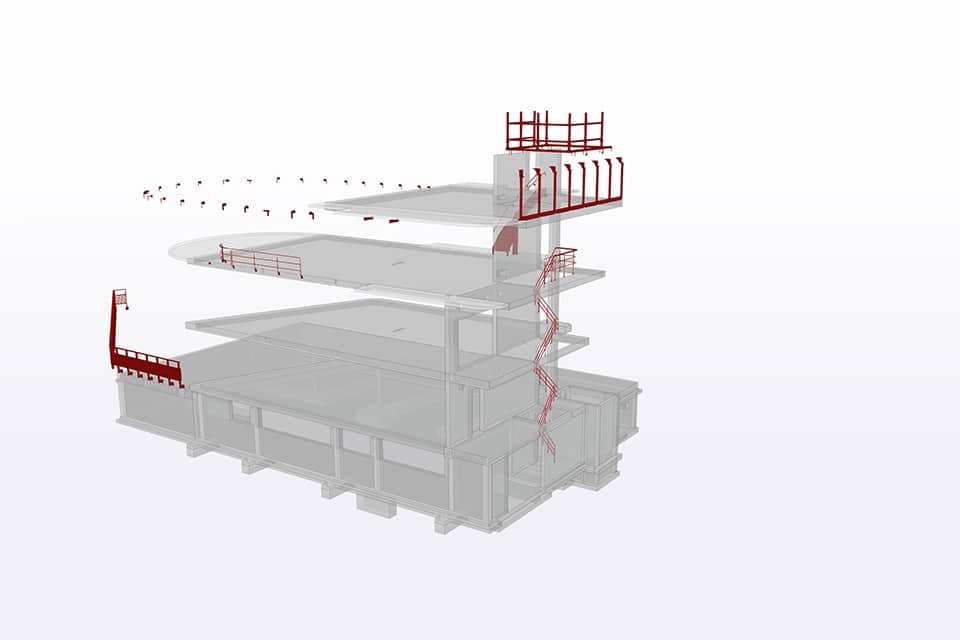

For 32 years Hoogenboom Staal B.V. has been the address for a variety of constructions, stairs and fencing in steel. Currently, the steel specialist from Nieuwveen is involved, among other things, in the construction of the new control center on the Scheveningen boulevard. "Commissioned by BESIX Nederland, we produce, deliver and assemble the quay fencing, a balcony fence for the window washers, the fencing and balustrades for the concrete stairwell and a staircase from level 3 to the installation room," says Niels Bader, owner and director of Hoogenboom Staal B.V. "We also take care of various additional work orders. So in the control center, our craftsmanship comes into full play."

The quay fencing involves strip steel fencing based on strip profiles, which is securely anchored to a concrete element under the pavement, Bader says. "The balcony fencing, in turn, consists of tubular profiles. For aesthetic reasons, an oval profile is used for the top rail. The balcony railing is mounted in front of the sloped windows of the control center and helps ensure that the window washers can work safely. A rounded gate at the end of the balcony railing also guarantees easy access."

The concrete stairwell will be fitted by Hoogenboom Staal B.V. with stainless steel railings with bars and intermediate rails of tubular profiles, combined with a wooden handrail, Bader says. "Finally, the staircase to the installation room will be executed as a closed staircase of cut strip steel and set steps. As an additional work order, we attached outriggers to the top line of the main structure, to which the rail system for the window cleaners can later be attached. At the level of the installation room, we made the rear structure for the cladding. And we also made an auxiliary structure on the roof."

Because of the position of the building, directly on the North Sea, all steel parts that come into contact with the salty sea climate must meet corrosion class C5-M (maritime). Hoogenboom Staal B.V. meets this requirement by hot-dip galvanizing the steel parts and providing them with a three-layer powder coating. In order to fine-tune the design and detailing of all steel parts, in the preparatory phase the steel specialist engineered all parts in Tekla Structures and exchanged them with BESIX's coordination model via IFC.