900 tons of steel and 7,000 hours of skilled labor

DC Cotap: steel construction with guts and logistical insight

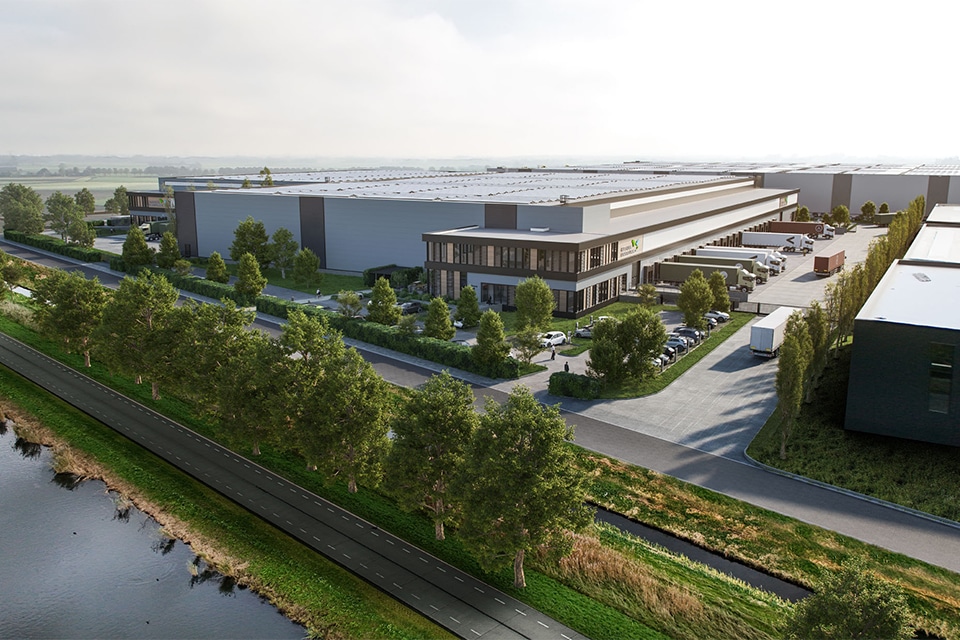

The new distribution center of flooring wholesaler Cotap in Zwolle was built at a rapid pace, with Imetaal Staalbouw as the specialist for the complete steel construction. A large-scale project and technically complex, but with a remarkably smooth process.

Imetaal Steel Construction specializes in steel constructions that you can say hello to. Not a giant in size, but big in strength. "We employ about sixty people and are currently busy modernizing our factory," says general manager Wilfred Kemperman. "We are doing everything to work even smarter and faster, now and later."

This future-oriented approach fits well with the assignment for Cotap, which is relocating part of its logistics activities to Zwolle. A new distribution center is being built there to replace the many external storage locations and centralize logistics. It was Imetaal Staalbouw's task to realize a complete steel structure that embraces the future.

Engineering down to the last banister

For Cotap's distribution center, Imetaal Staalbouw provided, among other things, the main load-bearing structure, including stairs, landings and fencing. "We did the engineering based on the main structure and worked everything out to the detail level," Kemperman explains. "Then the steel was produced in our plant, transported and assembled on site in bite-sized chunks."

900 tons of steel in 14 weeks

It was a big job: 900 tons of steel, 7,000 production hours and over 200 trusses. "We were on construction for fourteen weeks. Then everything has to be tightly planned," Kemperman says. "The biggest challenge is in the logistics. Everything has to fit together seamlessly: drawing, production, transport, preservation and assembly. Often assembly runs faster than production, so you have to think ahead. Fortunately, that went perfectly. No delays and a good atmosphere: the dynamics in the team were top notch."

Digital and solid

Imetaal Steel Construction has been working entirely in 3D for years, using modern techniques such as BIM. This ensures overview and accuracy in all phases. "This way, everyone knows exactly what needs to be done. And that is reflected in the result." That result is one to be proud of, says Kemperman: "You start with a bare surface and months later there is a gigantic hall. Then I think: we just did it together. That is the most beautiful thing about our work."