'Building refrigerated warehouses requires a specific approach'

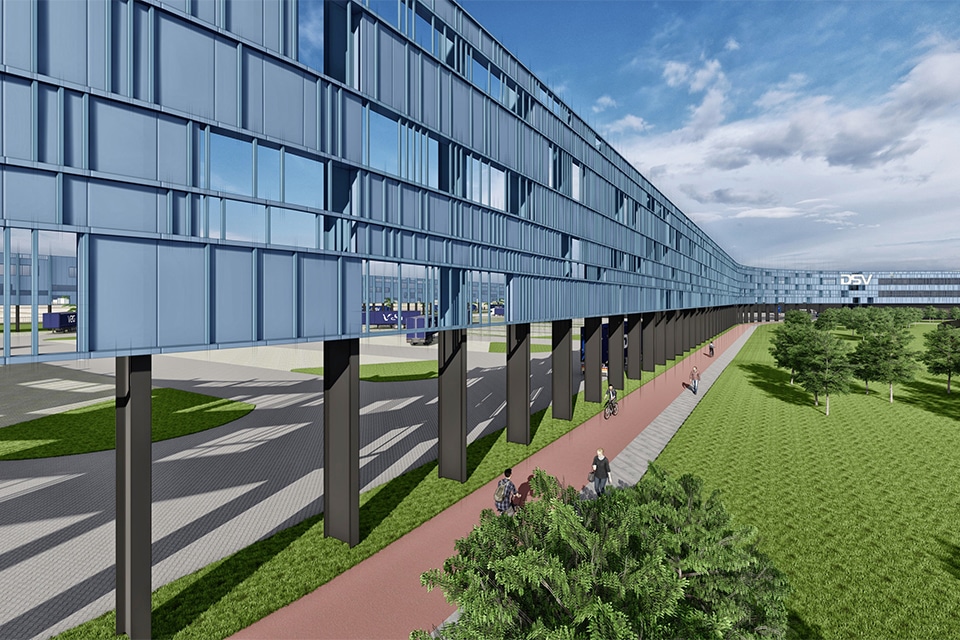

With over 40 years of expertise in food projects, architectural and engineering firm RBK Food Projects, part of RBK Group, was the party of choice for the design and construction supervision of DL Logistics Group and Jocotrans' new, sustainable logistics center in Bodegraven.

"In 2018, DL Logistics Group purchased a 12,000-square-meter lot at Rijnhoek business park," says Theo Vliek, Commercial Director at RBK Group. "We were then approached for the design process. We often take on the complete, integral design for the building and building-related installations. For this project, however, we worked with architect Frank Loor, who was already involved in the project. We focused on the internal logistics, structural detailing, electrical and mechanical installations, as well as refrigeration technology. Working closely with our client, we sought to optimize the distribution of shipping areas, pallet spaces and refrigeration/freezer cells. We also examined various types and distributions of racking. Certainly no sinecure, because in this project we were dealing with two users. Whereas DL Logistics handles the inbound, storage and outbound of dry, luxury, organic and conditioned products during the day, Jocotrans provides cross-docking of goods in the evenings."

In accordance with the BREEAM certification criteria, a comprehensive monitoring system with some 30 kWh meters and heat meters was installed. Chosen was the FOPRO® total management system from sister company RBK Automatisering, which provides insight into and can influence all energy flows in the building.

All-electric and BREEAM-NL 'Outstanding'

Uniquely, the logistics center operates all-electric/gasless. For example, the waste heat from the refrigeration plant is used to heat the offices, Vliek says. "In addition, the refrigeration system has the ability to run harder when the sun's intensity increases, allowing for cooling with 'free solar power.' Solar panels will be installed on the roof and energy-efficient LED lighting has been chosen throughout the building, giving us the very highest sustainability score. BREEAM-NL 'Outstanding'." In accordance with BREEAM certification criteria, a comprehensive monitoring system with some 30 kWh meters and heat meters was also installed. The system chosen was the FOPRO® total management system from sister company RBK Automatisering, which provides insight into and can influence all energy flows in the building.

Gas cooler and outdoor air cooler.

Construction supervision

RBK Food Projects recorded all the basic principles from the design in work specifications, which were then put on the market. "For each discipline, three parties were allowed to submit an offer, which we checked and supplemented where necessary," Vliek says. "This allowed us to compare apples to apples and select the best fitting partners for this project. Both in approach, quality and price. And good construction partners we found!" During execution, RBK Food Projects provided construction supervision for the facilities. "Our people were regularly present on the construction site to check the logistical, construction and installation work in accordance with the specifications. Over the next year, we will also take care of the monitoring and fine-tuning (commissioning) of the climate installations, in close cooperation with the installation parties. As a result, DL/Jocotrans will receive exactly the level of comfort, efficiency and sustainability promised to them at the front end."