Smoothly collaborate on a sleek loft

This is reflected in the multi-functionality of the building, but also in the working method. With this new construction project, Hercuton shows how 'modular construction' and 'moving with the wishes of the customer' go hand in hand.

The new building will be built on the de Dijk industrial estate in Maassluis and will cover more than 24,000 square meters. The complex forms a representative extension to the existing office and storage capacity of MTS Euro Products. In terms of sustainability, the aim is to achieve BREEAM 'Excellent' certification. "This is the second time we have built for this client," explains Hercuton's Commercial Manager Ron Drijver. "Based on the pleasant, previous cooperation, we have been thinking along in the design and execution since the planning phase."

Loft architecture

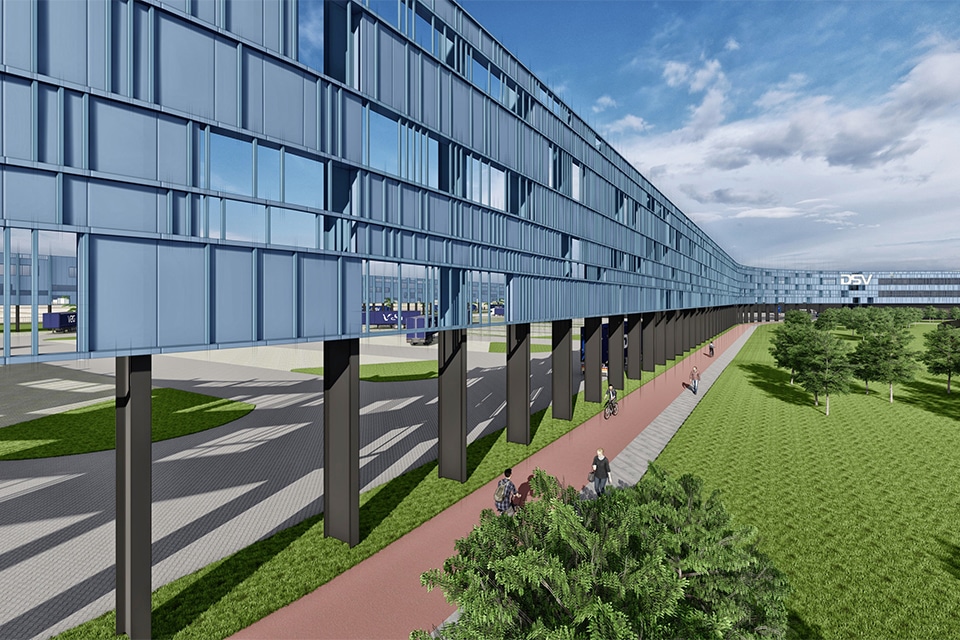

Aesthetically, MTS Euro Products had one main desire. "Like the previous building, we had to execute the new headquarters in loft architecture," says Drijver. "The client is very fond of this sturdy, industrial architectural style in robust precast concrete. It is characterized by high, open spaces and lots of light. We were given a lot of freedom to design the five-story office in this style." Hercuton combined the precast concrete shell with a curtain wall. The large amount of glass enhances the light, spacious character of the loft building and provides unobstructed views of the nearby water. Physical interaction with the surroundings is made possible by the continuous balconies around each floor.

Future-proof and safe

"While designing, we thought along in smart solutions," Drijver continues. "For example, with a view to future-proofing. The construction, consisting of concrete columns and steel girders, eliminates the need for load-bearing walls. That makes the building flexible in layout and thus easy to adapt to any future requirements. What also contributes to the future-proofing of the building is that concrete is very easy to maintain. If you look at fire safety, concrete is the material of choice for fire compartmentation."

Multi-purpose hall

The distribution center consists of a large hall with two branch offices and twenty docks. The building is constructed of a high concrete plinth and a steel structure with sandwich panels. The hall is sprinklered and has several storage areas and a mezzanine floor. There are solar panels on the roof. Drijver: "During the design of the distribution center we also thought along with the client in terms of smart solutions. For instance, together with the client we arrived at an efficient routing of the machinery. With a view to flexibility, we advised making the building as multifunctional as possible. The hall has a market-conforming grid and a free height of at least 12.25 meters."

Modular construction

With the pile driving work, the new building started in early November 2020. The concrete shell for the office and the steel structure for the hall have now been completed. By July 2021, both building parts will be wind and watertight. "We build everything according to our modular construction method," says Drijver. "We prefabricate the concrete and steel elements under conditioned conditions. This greatly benefits quality. As a result, on-site assembly is only a logistical process, which can be planned to the day."

Engineering on the job

By paying close attention to preparation, Hercuton hardly encounters any surprises during execution. At the same time, this tightly organized process leaves room for 'engineering on the job'. Drijver explains, "Sometimes you come to changed insights during construction. We move with these as much as possible. We advise on the best solution and point out any consequences. In some cases you have to go back to the drawing board. That was also the case on this project, for example, when it turned out that one of the balconies had to be tripled. Such an adjustment requires the necessary flexibility from both MTS Euro Products and us, but that is precisely where we find each other. Moreover, it contributes substantially to the final picture we all have in mind. We are eagerly looking forward to the delivery."

Project info

'Growing together'

Hercuton and facade builder JM van Deft & zn. have had an intensive partnership for many years. In the past, they have already joined forces to build an office and business premises for MTS Euro Products. Because this company continues to grow, it has now outgrown its premises.

For the construction of the new logistics center and headquarters, both parties are once again involved. Again in Maassluis, but this time at a beautiful location right along the Maas River. The building with eventually four floors has been designed to be as flexible as possible in terms of layout and use. JM van Delft & zn. will supply and install almost 1,200 m² of aluminum curtain walls for this project. "The difficulty with this project is mainly in the assembly of the curtain walls," says project manager Albert Emmers. "Because the building is being built right next to the water, there is limited space on one side for assembly, but we don't turn our hand to that either. We are therefore proud to be able to welcome MTS Euro Products as a returning customer on behalf of Heructon."

Construction Info

Client

MTS Euro Products, Maassluis

Design

Hercuton, Nieuwkuijk