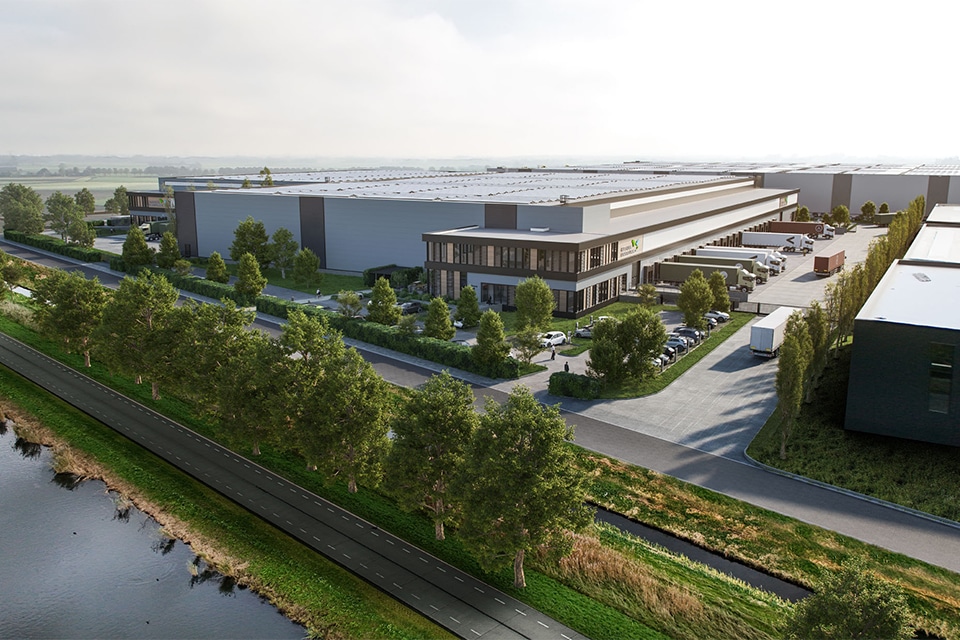

DC bol.com: 'Deformation requirements and horizontality were our biggest challenges'

In 2021, bol.com's new warehouse in Waalwijk will open its doors. The new distribution center is all about more mechanization and less walking distances for employees. Because of the strong focus on mechanization, the engineers of flooring specialist Van Berlo had to take into account additional requirements regarding horizontality and deformation of the warehouse floors. An interview with Glenn Verhoef, commercial director at Van Berlo.

Text | Roel van Gils Image | Van Berlo

The online marketplace's new warehouse is already the second building in Waalwijk. The first was commissioned in 2017, but is already proving too small. "At the time, we made the floors and foundations in the first 50,000-square-meter warehouse for contractor Van Wijnen and were asked again for the expansion, this time commissioned by Bouwbedrijf Van de Ven," Verhoef begins. "The new warehouse also has a floor area of 50,000 m², but also includes a section of mechanized high-rise buildings."

Van Berlo first poured 30 centimeters of concrete over the entire surface and then another 15 centimeters on top of that.

Complex shuttle floor

For Van Berlo, the project consisted of the realization of 24,500 m² of industrial floors including the installation of 3,300 Mini Vibro piles and 10,000 m² of shipping floors with 1,900 Mini Vibro piles underneath, the installation of 50,000 m² of pressure layers on the floors and the realization of 14,000 m² of shuttle floors in the fully automated warehouse. The flatness requirements for the fully automated warehouse were not particularly high, according to Verhoef. "However, we did have to meet the so-called FEM standards regarding horizontality and deformation. After all, a skewed floor can still be flat. In addition, the floor must not bend due to the high weight in the racks. Both issues do not exactly benefit optimal operation of the shuttle system." All this resulted in a floor 45 centimeters thick, due to the load of the automatic racking concept with shuttle systems up to 30 meters high. "The floor was poured wet in wet. That is, we first poured 30 centimeters of concrete over the entire surface and then another 15 centimeters on top."

The floor in the shuttle warehouse.

In addition to the challenging shuttle floor, Van Berlo also lent its expertise to realizing the pressure layers on the floors. "The storey floors were difficult to reach during construction," Verhoef knows. "We had to bridge a considerable distance of 250 meters(!) each time. That required good agreements with the concrete supplier about the consistency of the concrete composition. The mixture had to be able to bridge that distance, but also lead to a good floor. That all worked out perfectly in the end. Finally, we treated 37,000 m² of floors with Ashford Formula, a sodium silicate-based concrete impregnator for less dust formation and easy maintenance."