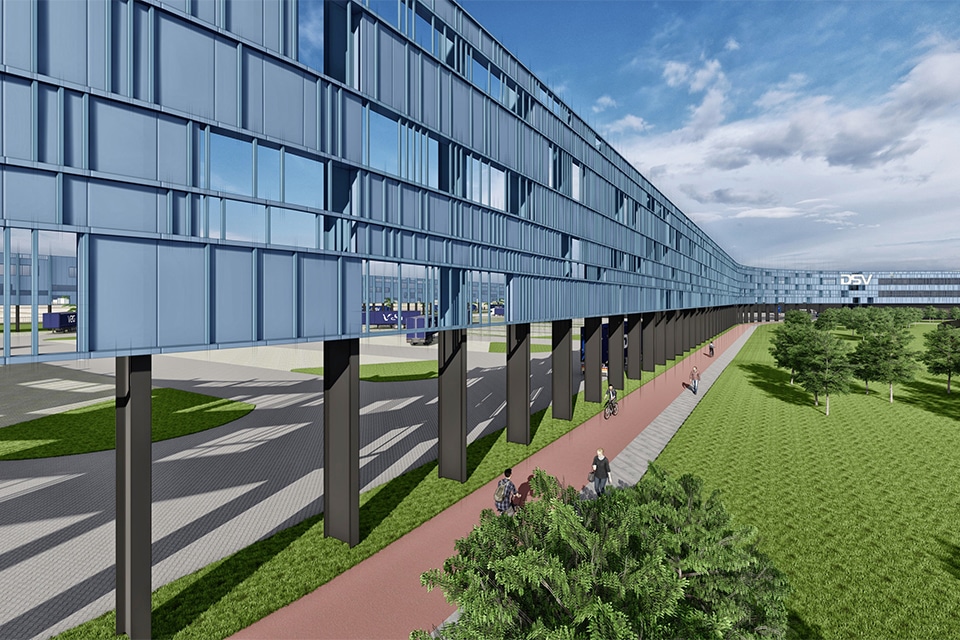

New refrigerated/freezer distribution center in northern Germany

DURABLE, ENERGY EFFICIENT AND HIGHLY AIRTIGHT

B-Built has been the Design & Build partner for the refrigerated and freezer storage sector for fifteen years. Both in the Netherlands and abroad. More than thirty employees design and realize high-quality tailor-made concepts, regardless of the nature, size and/or location of the project. Functionality, sustainability and logistical efficiency come first.

"Since our start, we have designed and realized more than 800,000 temperature-controlled pallet storage locations, with more than 6 million cubic meters of construction volume and fully supporting our customers' business processes," says Pim Meesters, Lead Engineer at B-Built. "In this process, customers are relieved of all their concerns from A to Z. That this working method is appreciated is proven by the many customers who keep coming to

return to us."

Ready for takeoff...

One of these recurring clients is an American world leader in the transportation and storage of refrigerated foods. B-Built has already designed and built several frozen (high-rise) warehouses for this client, including in Rotterdam and Lelystad. Currently, the Design & Build specialist from Bergen op Zoom is on the eve of the construction of yet another special refrigerated/freezer distribution center, at a strategic location in northern Germany. "The most important part of this new building is a frozen storage of more than 13,000 m2 with 2,200 m2 freezer buffer, 1,000 m2 shipping space and 14 indoor dock levellers," Meesters says. "In addition, we are realizing a 360 m2 palletization area with 4 indoor dock levellers and 200 m2 of loading space for forklifts will be provided. The outdoor area of 8,300 m3 will also be designed and realized by B-Built." The refrigeration system will be housed in a 300 m2 technical room, he says. "Next to the refrigerated/freezer distribution center will be an office building of 900 m2. The site preparation and explosives survey began in early October. In December, we will start the actual construction, which will take about 13 months; from the piling work to the delivery of the building and including the cool-down period."

Glycol-based extinguishing system

"Because we design and build for this client more often, we are well acquainted with its working methods, logistics and building needs," Meesters emphasizes. "Combined with our own structural and engineering knowledge, we can provide expert advice, accurate quotations and quick turnaround on projects." An important starting point for the refrigerated/freezer distribution center is that the building must be suitable for the goods of various customers. "For this reason, we chose to create one large frozen storage area with mobile racking and pallet conveyors. B-Built also provides the design and implementation coordination for the mobile racking system and the refrigeration system." A challenge here was to ensure fire safety and compartmentalization. "We solved this by integrating a glycol-based sprinkler extinguishing system." The frozen storage is realized in a steel skeleton with sandwich facade panels, sandwich roof panels and a cast-in-place insulated concrete floor into which the racking rails are integrated. "All connected spaces will be constructed in precast concrete, again with sandwich wall panels and sandwich roof panels."

100% airtight

Following on from accessibility and fire safety, there are also requirements for sustainability (BREEAM rating 'Very Good'), energy efficiency and airtightness. "To guarantee the very best insulation values, all of our freezing projects are realized with a minimum Rc value of 10.5," Meesters said. "The materials, connections and detailing of the new building are chosen in such a way that a high degree of airtightness is achieved. As a result, the desired low temperatures can be perfectly guaranteed without risk of leaks and energy losses. An extensive PV installation (1.67 MW) will be installed on the roof, which will soon allow our customer modulated cooling. During the day, maximum use is made of the energy yield from the solar poles, allowing one to lower the temperature a little further. In the evening and at night, this allows the cooling system to run at a lower capacity. Obviously within the critical limits (-20°C) imposed on the refrigerated/freezer storage of foodstuffs. In this way, the building functions as a large battery, resulting in significantly more favorable energy consumption. Making these and other customized optimizations possible requires specialist knowledge. Not for nothing are we the specialist for the cold and freezer storage sector."