24/7 best cooling performance at lowest energy costs

The new business premises for Kotra, specialist in Fresh & Frozen Logistics, required a central refrigeration system of the highest standard, built with the environment in mind. Van Kempen Koudetechniek made a well thought-out design for this and implemented it.

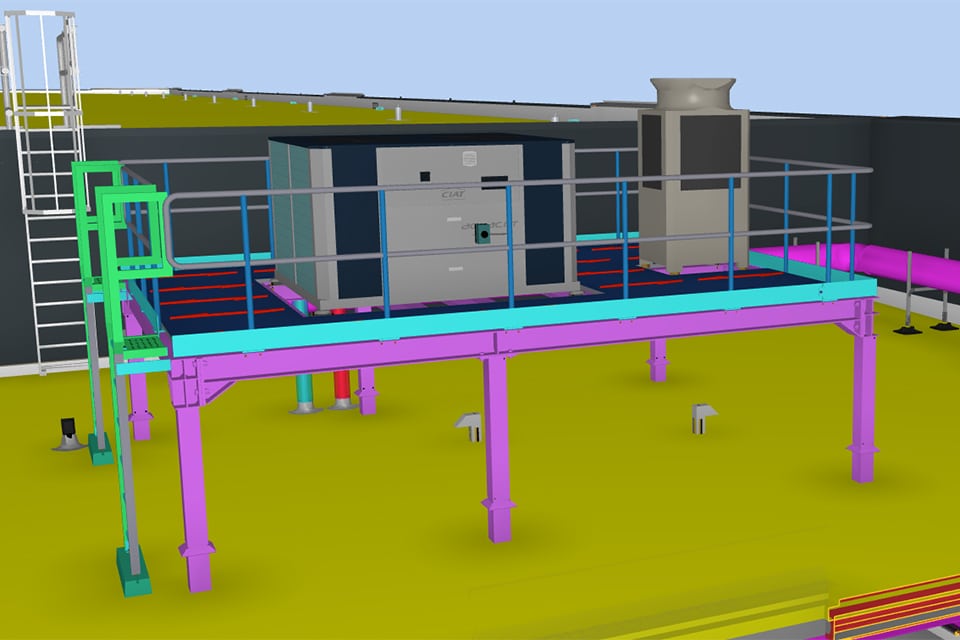

From the construction team, Van Kempen Koudetechniek made the design for a refrigeration/freezer system for the freezer cell, fresh cooling area, fresh fish area, processing area, shipping area and cross docking. It also connected two flake ice machines to the freezing system. All this was done as sustainably as possible and with minimal CO2 emissions.

Natural refrigerants

By using natural refrigerants, the new cold rooms do not contribute to the greenhouse effect at all. At the same time, they represent energy savings of 25% compared to HFC refrigerants. Last but not least, this made Kotra eligible for a tax subsidy scheme.

Reuse of waste heat

A second important step in the context of sustainability was the reuse of residual heat. "For this we installed a desuperheater, which recovers the residual heat and holds it in a hot buffer tank," says Frank Boeijen, Sales Manager of Van Kempen Koudetechniek. "This is now put to maximum use, including for heating the offices, defrosting and underfloor heating of the freezer cell. The central cooling system includes two freezer compressors and five refrigeration compressors."

VK-Dynamics operating system

The chillers are made entirely of stainless steel. In the processing rooms, the evaporator fans run at a very low noise level. They are also infinitely variable in air output by means of direct current fans. The sustainable installation is controlled by the VK-Dynamics control system. Boeijen: "This control system was developed entirely within Van Kempen Koudetechniek and guarantees the best cooling performance 24/7 at the lowest energy costs. The latter is our starting point with every project," says Boeijen. "Van Kempen Koudetechniek stands for 'Cold today. Cold tomorrow.'"