Customized solution for cold storage and freezer storage

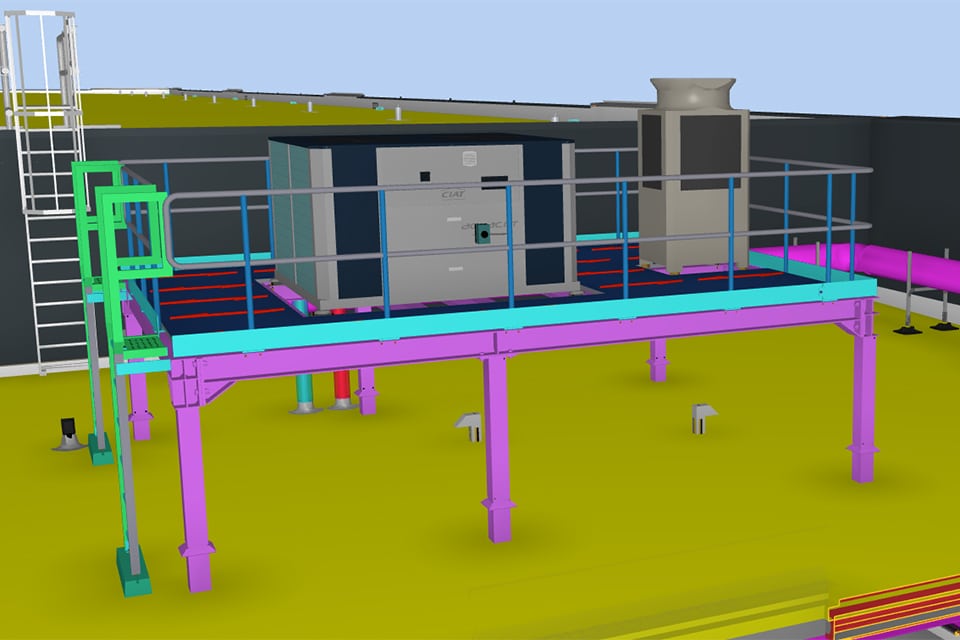

Nijssen has won the contract for the expansion of Lelieveld Transporten. The work consists of the plant expansion for an NH3 pumping system for cold storage and an entirely new CO2 plant for freezer storage.

Residual heat from the CO2 plant is used to heat a glycol de-icing system, to be used in both the refrigeration and freezer cells, thus completing the plant deliveries. PLC controls with visualization ensure efficient and controlled plant operation and provide the user with options for a completely worry-free remote management.

Since its establishment, Lelieveld Transporten has specialized in the conditioned transport of food products. The site in Hazerswoude-Dorp has 11,500 m2, with 8 docks, 2,040 m2 of refrigerated warehouse, its own garage and around 30 truck spots. 'Dedicated transport' is provided from several locations, entirely in line with customers' requirements and house style. Naturally, Lelieveld Transporten works according to the applicable food safety standards. The FSSC certification has been completed and with this the 22000 GFSI accredited certificate was obtained in September 2019. This underlines how responsibly it handles food safety for conditioned and unconditioned transport and storage and transshipment of foodstuffs.