Biosintrum, Oosterwolde | 'A great way to show possibilities of biobased building'

Nature has a lot to offer us, something we often forget. With this in mind, Halbe Vlietstra, building biologist at Oldenboom, is working with various parties to put bio-based building on the map. Together with a number of these parties, he made an important contribution to the Biosintrum in Oosterwolde.

Vlietstra is employed at Oldenboom, a family business that has traditionally specialized in the trade and processing of, in particular, wood and panel species, building materials and interior products. Since 2006, Oldenboom has also specialized in ecological building materials. "Through an ecological housing project I came into contact with bio-based building," Vlietstra says. "I found it extraordinary what those natural materials did to the home in question. I began a search for the possibilities of biobased building. Soon I became convinced that this is the best way to build. It became my mission to bring that to the attention of the construction industry."

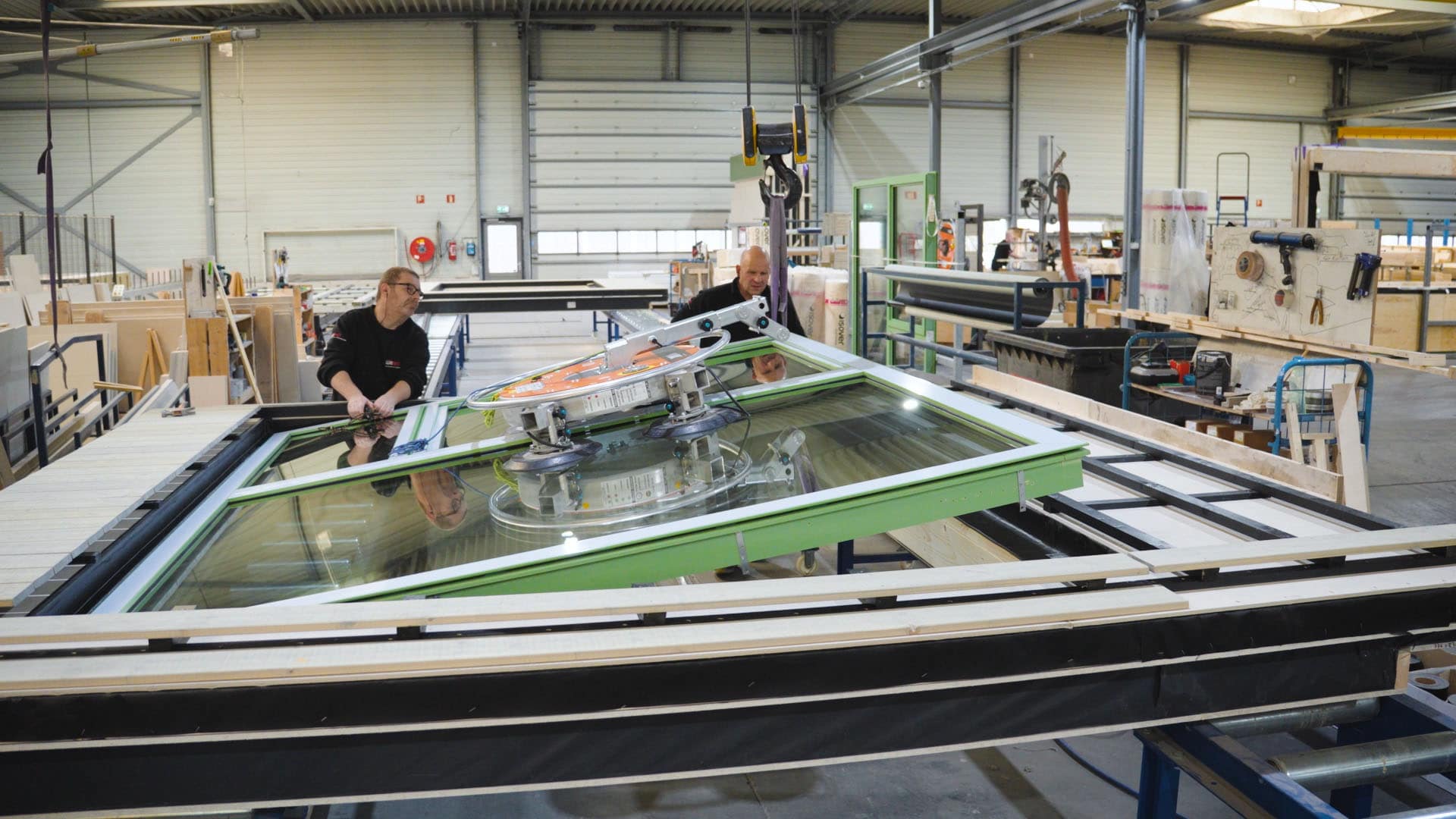

Structural and insulating materials

"The Biosintrum is a great way to demonstrate the possibilities of bio-based construction," Vlietstra continued. "At an early stage of the project, I sat down with Rob van der Hoek of Buiteveld. Based on the design, I looked at what I, on behalf of Oldenboom and in cooperation with the parties in my network, could do for the Biosintrum. From that, five products emerged. These were mainly structural and insulating materials, which we had applied before on other works. For all these products, we were able to provide the "environmental product declarations," the so-called EPDs. This was necessary within the framework of the BREEAM certification."

Wood fiber boards and old newspapers

For the exterior of the Biosintrum, Oldenboom supplied pressure-resistant water-resistant wood fiber boards. These boards are produced in Meppen, Germany, from wood mostly from Dutch forests. The spaces between the posts of the facade are fitted with partly circular, flexible wood fiber insulation boards and partly cellulose insulation. Vlietstra: "For the cellulose insulation, we collaborated with InblaasNoord from Surhuisterveen. This insulation consists of crushed old newspapers that are blown into the construction. The cellulose we used in the Biosintrum is a 100% organic insulation material that can absorb about 20% of its weight in moisture. Furthermore, it has good acoustic and fire retardant properties." In cooperation with Juro Coating of Heerenveen, Oldenboom supplied finished wood fiber boards, partly acoustic, for the inside of the building.

More than 2,200 pairs of jeans

The Biosintrum also uses acoustic insulation material made from jeans. "There is a beautiful story behind this," says Vlietstra. "As the final client of this project, the municipality of Ooststellingwerf wanted to showcase as many ecological materials - and their possibilities - as possible. It devised a playful action to make the concept of bio-based building tangible. She called on residents in the municipality of Ooststellingwerf to turn in their old jeans so that they could be made into insulation material. That was a great success. The acoustic insulation of the Biosintrum required 2,200 pairs of jeans. We got a lot more!"

Exceptionally high airtightness

To make the Biosintrum air- and windproof, Oldenboom made a Plan of Action in the preliminary phase with the company Pro Clima. This German company supplies ecological products for air and wind sealing, sealing any seams. "With Pro Clima's products, the connections in the Biosintrum were sealed," Vlietstra said. "After construction was completed, the building was subjected to an airtightness test in the presence of Pro Clima. The results were exceptionally good. The required qv;10-value was 0.25. The Biosintrum ultimately achieved a qv;10-value of 0.12."

Reachable for all

"Biobased buildings are healthy and comfortable," Vlietstra continued. "We think it is important that this becomes accessible to everyone. Fortunately, more and more municipalities, companies and clients are noticing that they can do much more with nature than was thought for a long time. And we also do away with the argument that bio-based construction is too expensive. For example, we were involved in the construction of six bio-based timber frame starter homes in the social housing sector. We also supplied biobased materials in the construction of 24 apartments for people with mental disabilities. So quite a lot is already happening. We need to share this with the industry and the outside world. I am therefore pleased with a sensational project like the Biosintrum. And proud that we as Oldenboom have contributed to it."