Secure attachment in just a few minutes

Structural thermal breaks for retrofitting balconies

Leviat is a world leader in lifting, connecting and anchoring technology for construction and industry. "Our main objective is to increase efficiency and safety on construction sites," says Gerko van Gortel, Sales Engineer Concrete Department at Leviat. "We also help contractors and concrete manufacturers to build quickly, sustainably and circularly."

"Around us, we see that construction sites are becoming smaller and smaller, leaving no room for heavy underpinning. Safety requirements are also becoming more stringent," Van Gortel said. "Combined with the severe shortage of skilled workers, prefabrication is increasingly being chosen, where complete elements are assembled under the best climate and working conditions, delivered just-in-time and lifted directly from trucks into the building frame. Leviat goes along with this with a complete range of lifting, connection and anchoring systems for floors, walls and precast balconies, which enable contractors and concrete manufacturers to build in a demountable and therefore sustainable and circular way. Without sacrificing strength, rigidity and stability."

Dry, quick and safe assembly

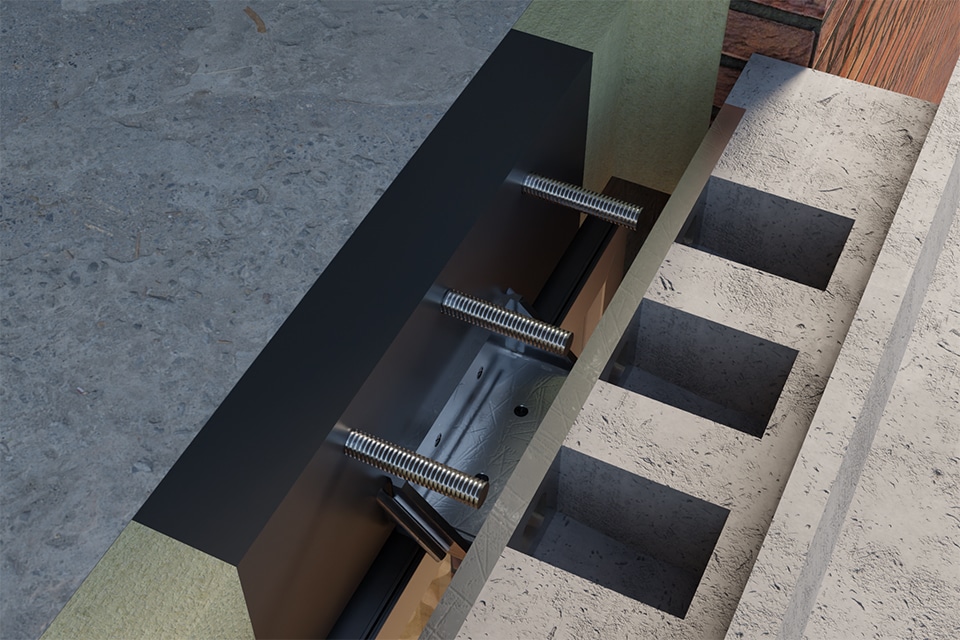

Specifically for precast balconies, Leviat is introducing a new range of Halfen HIT-PI (Post Installed) structural thermal breaks, which allow precast balconies to be securely attached to the building structure directly from the crane and in just a few minutes. "Halfen HIT-PI eliminates the need for temporary support/underpinning because assembly no longer depends on the curing time of the concrete," says Van Gortel. "Halfen HIT-PI can also be adjusted in all three directions; an important feature for fast, trouble-free installation. Only a few nuts and follower plates are sufficient for fixing the precast balconies." The balconies can be loaded immediately after assembly.

Durable cutout blocks

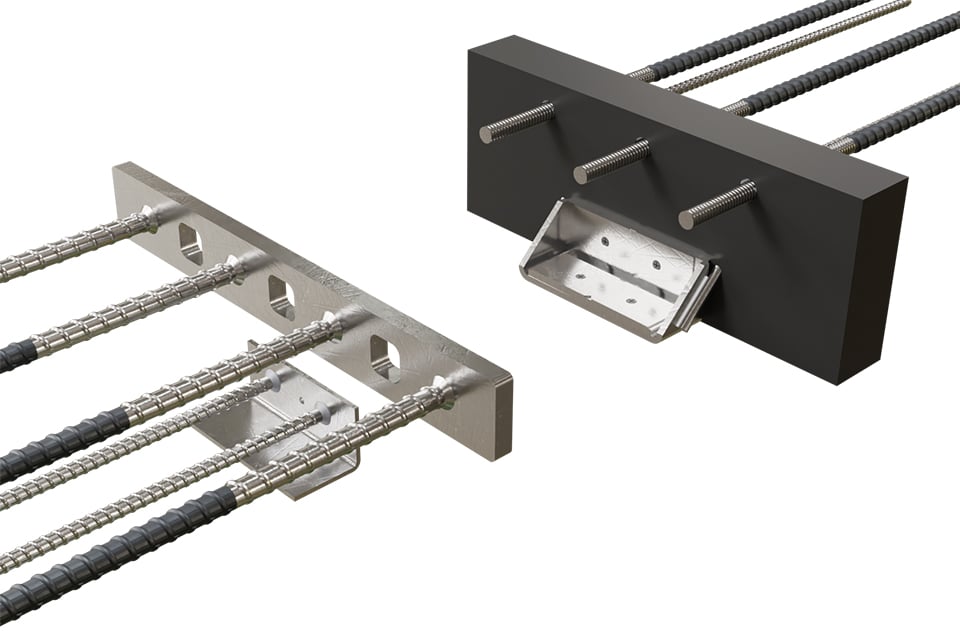

Halfen HIT-PI consists of several components, which are delivered to the precast concrete supplier and contractor, Van Gortel said. "As desired, fixing can be done on the balcony side (type HIT-HP PI-B) or on the floor side (type HIT-HP PI-F). Durable recess blocks help to create the appropriate recesses for this and can be used again and again. This also meets the sustainability ambition of more and more clients."

HIT-PI element sets

Depending on the installation method, size and weight of the balconies, Leviat calculates the appropriate HIT-PI element sets, says Van Gortel. "We consider the correct pouring positions and elaborate our recommendations in an anchoring proposal. For attachment on the balcony side, the tensile plates and L-steel profiles are delivered to the precast concrete supplier, while the contractor receives an insulation box equipped with shear bars and load-bearing L-steel. For fixing on the structural floor side, tensile plates and an insulation box with transverse force bars and load-bearing L-steel are supplied to the contractor, while the precast concrete supplier receives tensile bars and L-steel profiles. For most balconies, two HIT-PI elements provide sufficient capacity to support the full load."

Meanwhile, the first projects with Hal-fen HIT-PI have been started. As an example, Van Gortel mentions project De Silo in Almere Nobelhorst, in which sixteen prefabricated balconies are suspended from the facades. "Special about this project is that the anchors have to be made in a sandwich facade element. Special specials have been developed for this, with which the flexibility of our Halfen HIT-PI anchoring systems

is underscored."