All-electric living in Zwolle-Zuid

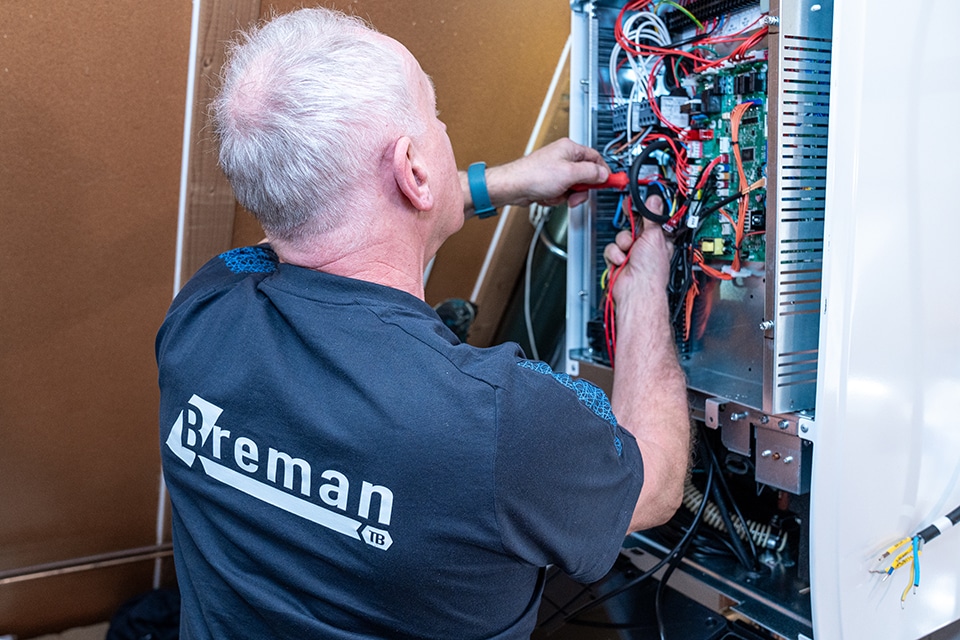

In the Oldenelerbroek neighborhood in Zwolle-Zuid, 151 homes will be sustainably renovated and made natural gas-free in just over a year. With this, housing corporation SWZ is taking a first major step in the route to a natural gas-free housing portfolio in 2050. While the structural work is being carried out by Nijhuis Bouw, Breman Techniek Zwolle (part of the Breman Installation Group) is responsible for the all-electric installations.

The renovation will take about 15 working days per home. During this period, quite a bit of sustainable renovation work will be done, says Project Manager Diederik de Jong. "The thermal shell of the home will be significantly improved by installing triple glazing and sealing seams and chinks. In addition, the homes will receive a new front door and a heat recovery system." Breman Techniek Zwolle is providing all the homes with an all-electric heat pump. "The air/water heat pump is connected to the existing central heating system. Based on the heat demand and radiator types per room, the system is then water-side regulated."

151 homes, 41 laying plans

To sustainably compensate for the extra electricity consumption due to the heat pumps, all homes will be equipped with PV panels. The starting point here is an output of approximately 3,000 kWh per home, says De Jong. "Because about half of the homes already have a PV system, the correct dimensioning was determined for each home. This obviously took into account the roof position and the mounting of installation components such as roof penetrations and heat pump exterior parts. As many as 41 different laying plans were created for the 151 homes!"

At the request of the Building Code Committee, all heat pump exterior parts were sprayed in an anthracite gray two-component paint. Then the exterior parts were prefabricated in Breman Techniek's warehouse and fitted with brackets and work switches. "Because of the difficult accessibility of the roofs, they are transported to the construction site in large batches of 15-20 units and lifted directly to their positions on the roof with a telescopic handler."

Precise power distribution

"All kitchens will be equipped with an induction cooktop and - if not present - a recirculating hood," De Jong says. "Old meter boxes will also be replaced by new meter boxes with a heavier connection (3x 25A). We went through an extensive process with Enexis to coordinate the infrastructure for this." Because Enexis will not start the modifications to the ground network until the end of this year, Breman Techniek Zwolle has carefully distributed the available power for the homes. "Residents are asked to run the heat pumps as constantly as possible. Also, the anti-legionella function of the hot water boilers is activated per residential block and during night hours." By April 2025, the work should be completed.

Heeft u vragen over dit artikel, project of product?

Neem dan rechtstreeks contact op met Breman Installation Group.

Contact opnemen

Contact opnemen