Doka formwork and scaffolding for renovation of Voest Bridge

The Austrian Voest Bridge demonstrates Doka's strength as a total provider for the supporting essential renovation projects with versatile formwork and Ringlock scaffolding solutions

Doka, the global leader in formwork and scaffolding, is adding value to renovation projects by enabling construction companies to use the Ringlock scaffolding system intelligently on renovation projects of any size. The recent repair and renovation of the important Voest Bridge shows how the modular scaffolding system played an important role in supporting the repair of one of Austria's busiest road sections on the A7.

When the bridge over the Danube was built in 1972, it was the longest bridge in Austria and the first cable-stayed bridge built in the country. With an average of more than 100,000 motorists crossing this section of the A7 Mühlkreis highway each day, the bridge needed maintenance to carry the constant flow of vehicles.

Construction company Strabag SE had to support a 65-meter-high steel pylon without tensile anchorage. Doka's solution encased the pylon with Ringlock scaffolding and provided a safe working platform at all levels for on-site maintenance of the supporting structure. The high flexibility of Ringlock made it possible to create an integrated staircase and connection options to facilitate the installation

of a material elevator possible. Ring-shaped push rods supported the load, and the versatility of the proven modular system made it easy to adapt the scaffolding to the needs of the floor plan. Construction workers could work safely knowing that the Deutsches Institut für Bautechnik (DIBt) had certified the scaffolding system. The streamlined

cooperation between Doka and scaffolder Pecan GmbH contributed significantly to the smooth running of the project within the planned three-month deadline.

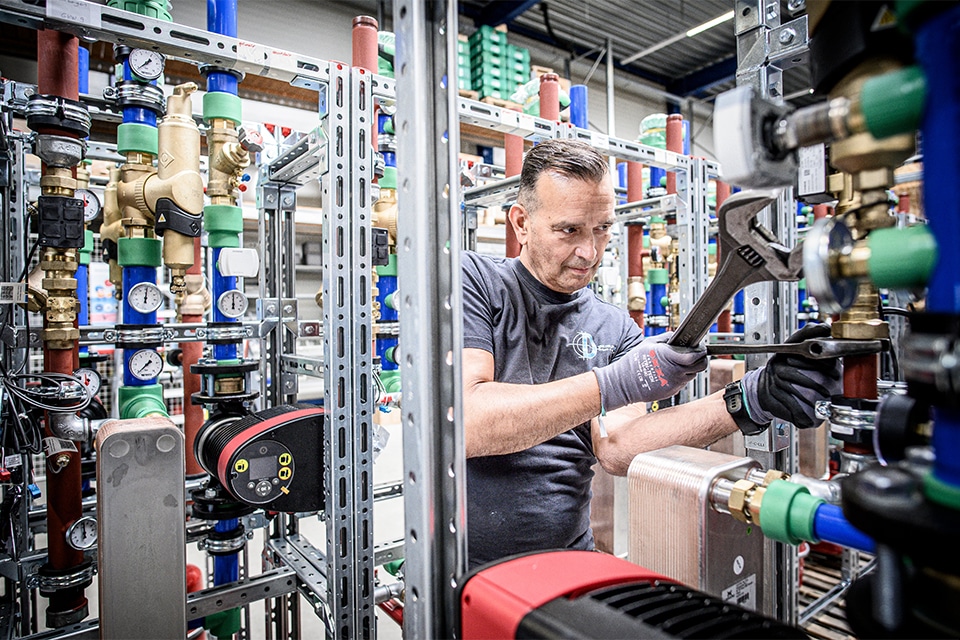

Copyright: Clean Frame Photography

Winning duo: formwork and scaffolding from a single source

Doka also played an important role from the very first stages of the bridge renovation project by supplying the formwork for the construction of the temporary bypass bridges directing traffic into the center of Linz, thus reducing the inconvenience to the city's businesses, residents and visitors. For Strabag and scaffolding construction company Pecan, a single point of contact for convenient, efficient and reliable scaffolding and formwork streamlined operations. Doka enabled the preservation of many existing components in the bridge structure, reducing the need for new construction and thus reducing costs and carbon emissions.

The collaboration with Doka ensured that the renovation could be carried out safely and seamlessly and added value to the project and the construction industry's commitment to carbon reduction. According to the World Economic Forum, carbon emissions can be reduced by 50% to 75% when renovating buildings compared to constructing an entirely new building. Doka is committed to reducing carbon emissions in construction and is expanding its support for renovation projects.

"The successful application of our Ringlock scaffolding system on such an important renovation project as the Voest Bridge demonstrates our innovative spirit, which is focused on improving construction industry standards, enhancing safety and providing products that reduce the industry's carbon footprint," put Robert Hauser, CEO of Doka. "We are proud to support renovation projects as well as thoughtful new construction projects.

Decarbonizing construction sites

Doka has set itself the goal of achieving "zero" net CO2 emissions by 2040. With its focus on decarbonization, the company has already calculated the carbon footprint for more than 7,000 products. Hauser: "Doka is committed to supporting a sustainable future through environmental transparency. In early 2024, we introduced carbon footprint data for our scaffolding products, marking a new milestone alongside our formwork portfolio. We are proud to be the first in our industry to do this." In this way, Doka provides transparent data on CO2 gas emissions, enabling customers to make environmentally responsible purchasing decisions in both renovation and redevelopment projects.

"We believe renovation projects will be an increasing part of our business in Europe and look forward to working with construction companies to rejuvenate old buildings, breathe new life into existing structures and restore civil structures that connect communities, such as the Voest Bridge in Austria," Hauser concluded.

In brief:

Project: General refurbishment Voest bridge

Location: Linz, Austria

Scope of work: Maintenance work on the existing pylon

Duration of the project: 3 months

Completion: June 2023

Principal for general renovation: ASFINAG

Main contractor: Strabag SE

Contractor scaffolding: Pecan GmbH

Systems Used: Ringlock modular scaffolding

Heeft u vragen over dit artikel, project of product?

Neem dan rechtstreeks contact op met Doka Netherlands B.V..

Contact opnemen

Contact opnemen