DOOR, Maasdijk | 'Engineering steel construction is a matter of thinking ahead'

On behalf of GS Staalwerken, ADS-Ertner engineered the complete steel structure for the new building of Coöperatie DOOR in Maasdijk. The size and composition of the complex were the main focal points.

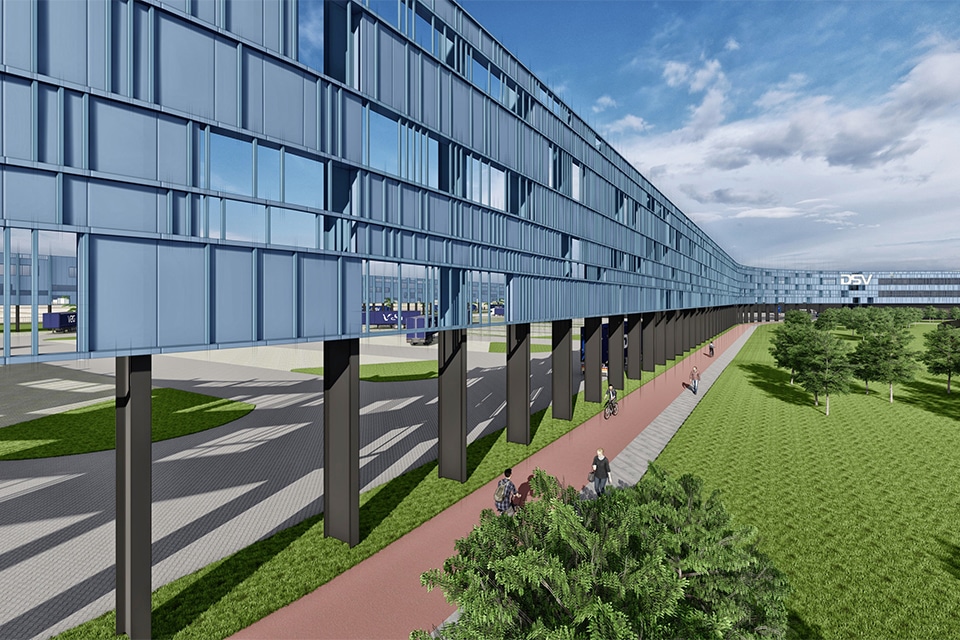

"The steel structure required over a thousand tons of steel," explains structural engineer/project manager Arco de Gelder of ADS-Ertner. "The complex has a total dimension of 170 x 140 meters and in terms of steelwork it can be divided into seven different parts: the front section that lies between the precast concrete, the hall on top of the precast, the office, the advertising accent, a heavy-duty garbage disposal, the ramp and the approach protection on the roof. These parts are built in a certain order, but had to be engineered as much as possible as one unit. Especially since prefabricated parts are used. The drawing, calculation and coordination of all parts was therefore done as much as possible during the preliminary phase. The time we put into this pays off in a smooth and agile execution."

Points of interest

"Within this set of components, the connection of the steel to the precast concrete at the front of the hall required a lot of attention," De Gelder continued. "Especially about the connection details, we had a lot of consultation and coordination with Kaskon. the engineering firm that took care of the precast concrete part. Other than that, it was mainly a matter of thinking ahead, to make the steel structure serve the components connected to it as well as possible."

Other points of attention were the edge protection, which had to be mounted around the slender designed steel ramp, as well as the office. De Gelder: "Because of the enormous size of the distribution center, it may not be so noticeable, but with five floors, the office is quite large. You rarely see offices of this size at distribution centers. In addition, the office has a considerable overhang, so the construction contains heavy details."

Constructive node in the office. | Constructive node in the advertising accent.

Communication and collaboration

Now that most of the steel is in production or already assembled, ADS-Ertner's work is on this

project is largely over. "It was a complex and, due to the time pressure, intensive project," De Gelder looks back. "Despite that, the engineering process went well. The clear communication and pleasant cooperation with the other engineering firms - Kaskon and IMd Raadgevende Ingenieurs - certainly contributed to this. We really created this work together and the executing parties are reaping the benefits of that."