Integral realization of floors offers quality and planning certainty

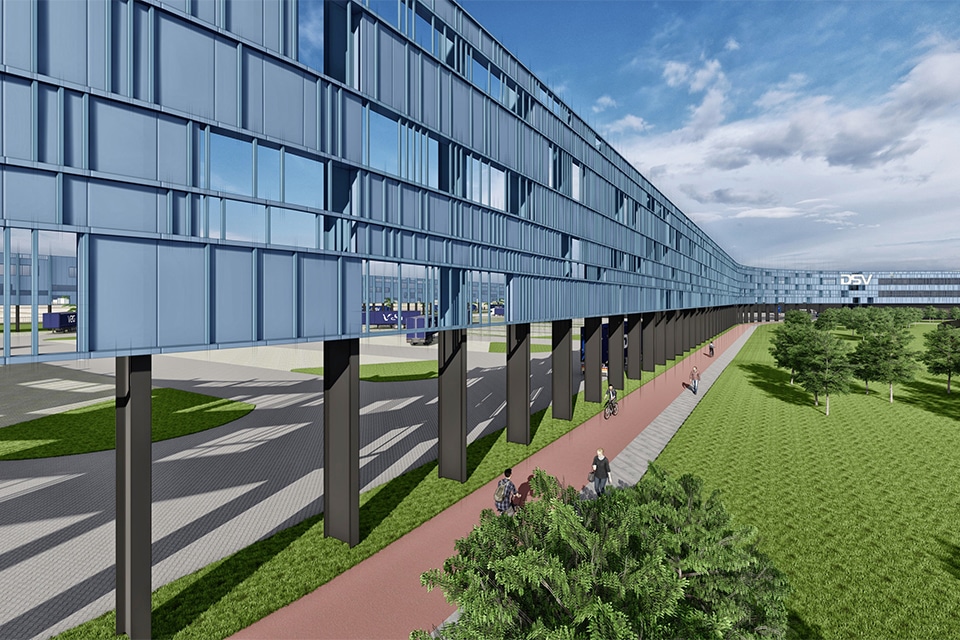

Van Berlo was able to provide the entire substructure of DC Lekkerland for client Bouwbedrijf Remmers and developer Montea. The industrial floors were constructed in high flatness and provided with Van Berlo's mini vibro-piles for foundation purposes. The building foundation was carried out in its own semi-prefab foundation system. "Van Berlo was able to deliver its complete expertise within the contours of the project," says technical commercial consultant Michiel van Zon.

Van Berlo focuses on high-end wholesale logistics, aiming to provide distinctive customization within these projects. "All parts were designed by Van Berlo's in-house engineering department, which allowed for an optimal coordination between the different building components. Not only does this deliver an economical solution, but by optimizing material use, it also automatically delivers a more sustainable solution. With distinctive customization, Van Berlo contributed to a high-end total solution for realizing an excellent logistics operation, based on maximum input of expertise."

Mini vibro poles

In numbers, this work consists of approximately 50,000 square meters of high-end floor space with a total of 15,000 mini-vibro-piles for the foundation. "This high number in connection with the ground conditions and the desire to achieve as little settlement as possible." The entire building foundation was realized within a time frame of 10 weeks. "In this case, it involved expanding a first phase by another 50,000 square meters. We also realized Phase 1 in good cooperation with developer Montea. With Remmers, the contractor of phase 2, we have carried out several projects as a partner. Quality and construction time are optimized at distribution centers; there is little margin for error. That requires parties that can carry out the entire process from foundation to floor finish."

Double floor

"After the pile driving, we left the construction site temporarily and the steel structure was erected and made wind and watertight by other parties," Van Zon continued. The latter was a prerequisite for Van Berlo before starting the realization of the interior floors. "There were high user requirements, which is why we also set requirements. For example, the refrigerated part is extensive and expandable. That part is implemented with double floors: a subfloor with underfloor heating topped with a package of insulation and a floored top floor." The warehouse floors (with a flatness according to NEN2747 class 2) are impregnated, making the surface dust-free.

Unburdening

Van Zon: "With our own factory and a complete BIM working environment, we control the entire process. This results in quality and delivery planning being in order and other parties also being able to do their work on time. Of course, there can be setbacks along the way. Everyone knows: planning doesn't get any looser. We are at home in the world of distribution centers with high user demands from Material Handling parties. The requirements for the floors are also extensively discussed with these parties in the preliminary phase. We completely relieved the customer, together with the main contractor. Remmers wanted to outsource the complete substructure; we are the right party for that. We do not say for nothing: we take care of the entire process, from pasture to anchor bolt."