Facade builder chooses new strategic direction

The facade not only determines the appearance of a building, but also the identity and comfort of its users. Both aspects come into their own at ALUVO Geveltechniek B.V. The expert in facade technology has been the partner of choice for a wide range of aluminum facade elements for half a century. From curtain walls to frames, doors, folding walls and sliding doors, which have been engineered and produced at one new and central location in Nieuwleusen since the beginning of this year. The move is part of a strategic reorientation, of which a new director, a new management and a new working method are also important components.

As a facade construction partner, ALUVO focused for many years on smaller projects in commercial and (private) residential construction, from its branches in Apeldoorn and Nieuwleusen and based on Kawneer and Schüco profile systems. "An excellent strategy, which certainly ensured considerable growth after the acquisition of two former owners," says Perry Hermans, Managing Director of ALUVO Geveltechniek B.V. and ALUVO Services B.V. "For example, towards the larger projects. However, the organization forgot to grow along with it. The workforce was aging and the location and production also lagged behind, as did the investment in new machines and ICT. This made it increasingly difficult for ALUVO to keep up. Fortunately, this changed in May 2022 with the takeover by DELOS Group." For a year and a half, an interim director laid out a basic strategy for the future. Meanwhile, the search was on for a new, young and driven management as well as a director from the industry, which was found in Perry Hermans.

Systemic mode of operation

Under Hermans' wing, ALUVO's strategy is being further refined. "The basic lines are now in place," he says. "For example, our way of working has been adjusted. We have very deliberately chosen to structure our organization and to work from projects and project teams, where a project leader structures, follows and monitors all processes. Thanks to a systems-based way of working, calculation and work preparation, as well as ordering, production and assembly planning are increasingly integrated and digitized, creating considerable synergy benefits."

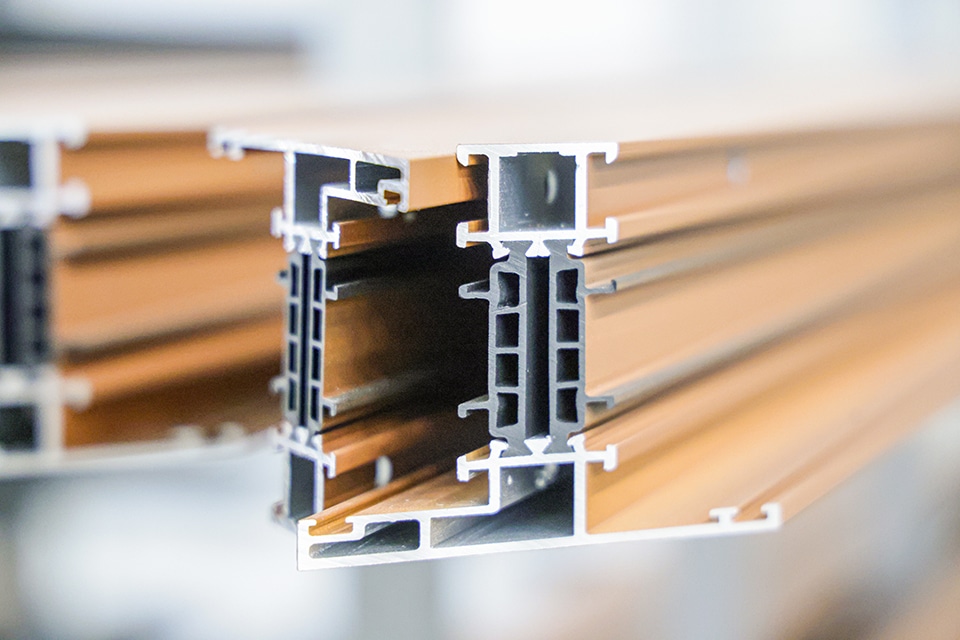

Attention to sustainability and circularity

"A more customer-oriented and process-driven approach with room for standardization was also chosen," explains Raimond Stassen, Sales Manager of ALUVO Geveltechniek B.V. "Today's trend is circular construction. In order to enable maximum reuse, facade systems must be produced according to fixed dimensions and assembled separately. After all, only then is exchange in projects possible. As an organization we are very committed to this, in cooperation with our partners. The aluminum we use must be produced sustainably. And the subsequent process must also be as sustainable as possible, where we pay attention to reuse and equivalent recycling. Moreover, sustainability relates to our customer and employee relations."

From one location

Synchronous with the above developments, a strategic reorientation of the production locations was also carried out. The ALUVO branches in Nieuwleusen (Rollecate 11) and Apeldoorn (Molenmakershoek 6) have been merged at a single location at Rollecate 83 in Nieuwleusen as of April 1, 2024. This creates an interesting cross-pollination, where employees can learn from each other and make each other sharper. "As a result, we become an even stronger organization," Hermans said, also citing the challenges of the merger. "We have been a small victim of Dutch grid congestion," he says. "Because our electricity connection was not arranged until much later, construction was unfortunately somewhat delayed and we had to organize our move during our production weeks. A huge challenge, in which the loyalty and understanding of our own employees as well as partners was very evident. Together we made a bizarre plan succeed, with production interrupted for only 100 hours. Since then we have been in a tremendously good flow and it is time to move on."

Quality and durable facade builder

ALUVO's ultimate ambition is to become the quality and sustainable facade builder for the future. For this reason, the organization is highly committed to quality assurance. ALUVO is a member of the Metal Windows and Facade Industry Association (VMRG) and holds the VMRG Quality Mark® and SKG-IKOB certification. "In addition, we operate our own quality system - the Internal Quality Control (IKB) - through which we guarantee that all our products meet the requirements set forth herein, including occupational health and safety and environmental requirements," said Hermans. "We comply with Safety Culture Ladder step 3 and organize our annual safety day. In addition, monthly toolbox meetings and workplace inspections are scheduled to encourage safe working. Our new management is also actively involved in this and can regularly be found on our construction sites. This is how we build together on one quality, sustainable and safe ALUVO."

Heeft u vragen over dit artikel, project of product?

Neem dan rechtstreeks contact op met Aluvo.

Contact opnemen

Contact opnemen