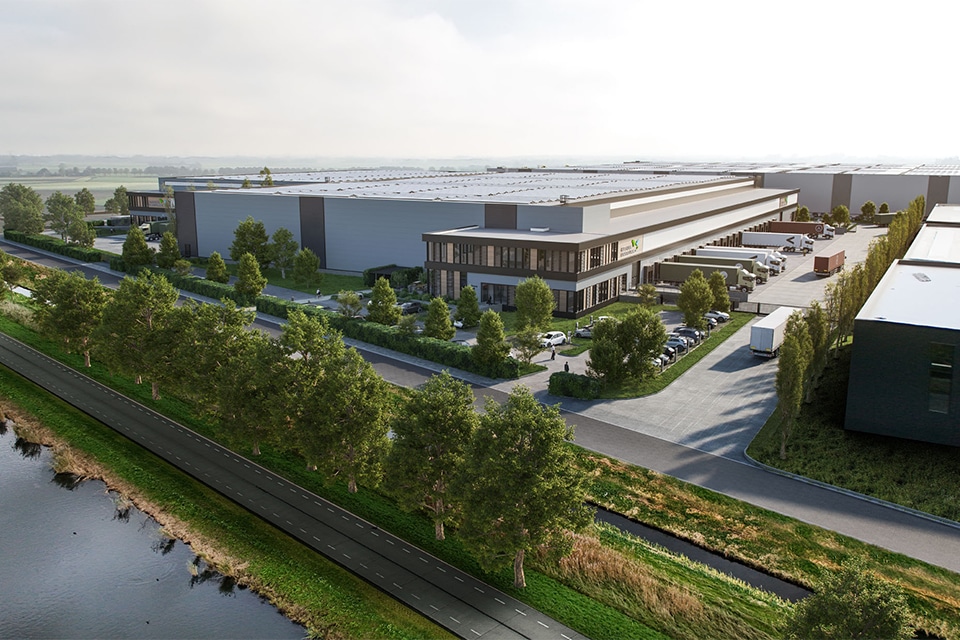

More than 40,000 m2 of sandwich panels for new distribution center VDH

In order to cool the fresh produce in VDH Forwarding & Warehousing's new distribution center at exactly the right temperature, Mucon is supplying and installing no less than 50,000 m2 of sandwich panels with an insulation value of 6.5 to 7.5. In addition, the specialist in conditioned spaces realizes a fire wall with a fire resistance of 60 minutes.

Eliminating cold bridges

From its offices in Zaltbommel and Varsseveld, Mucon realizes a diversity of projects. From cold stores and freezers to production locations and distribution centers for the meat and fish processing industry, AGF and agri sector. Clients are taken care of from A to Z. From the advice and design process to the delivery, assembly, service and maintenance of freezer doors, refrigeration doors and industrial doors, sandwich panels and wall and floor profiles. "We have extensive experience in the realization of conditioned distribution centers with interconnected cold rooms, which need to be cooled at different temperatures," says Kees de Jong, general manager of Mucon. "For example, to guarantee the quality and freshness of the stored products. In this case, for example, you have to deal with cold transfer through the floors and walls, which must be cleverly overcome. The solution to this already starts in the design phase, in which all cold bridges must be eliminated. For example, with steel breaks, sealants and foams. In addition, the insulation shell must be perfectly airtight."

Quality assurance with OpenSpace

Following the design, the people at work also play a crucial role, De Jong emphasizes. "They have to work in a very structured and precise way." For quality assurance, Mucon has been using OpenSpace for some time. "Our foremen wear a 360° camera on their helmet, which provides clear visual evidence of (the quality of) our work. This allows us to guarantee that all details are executed exactly as conceived in advance on the drawing."

BREEAM-NL Excellent

Work at VDH Forwarding & Warehousing's distribution center in Ridderkerk is being carried out on behalf of Aannemingsbedrijf Fraanje B.V. Mucon started installing the front wall of the cold rooms in week 8, says De Jong. "In week 12, the sandwich panels of the other walls and ceilings of the cold rooms followed, with an insulation value of 6.5 to 7.5. With this we are also making an important contribution to the BREEAM-NL Excellent ambition in this distribution center."