Customization for BWRI as a fun challenge

Scanning and drawing work

Visser Konstruktie Veenwouden is a steel construction company specialized in custom steel constructions. Everything is manufactured in their own factory and their employees assemble the parts on site. They see a custom project like BWRI Sappemeer as a nice challenge.

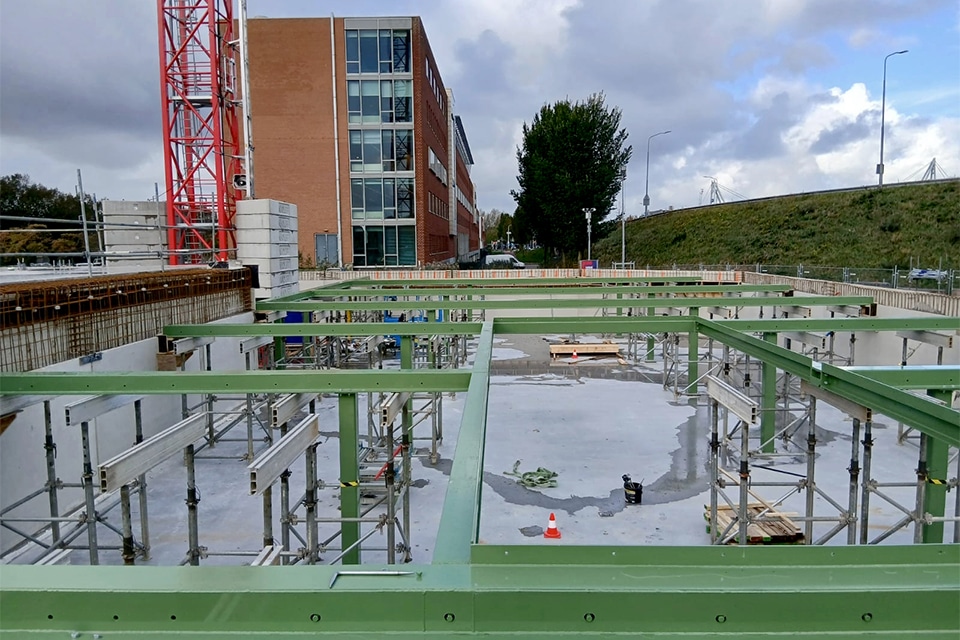

Commissioned by Hesco Bouw, Visser made a 3D scan of the existing steel structure. Based on this scan, the new steel was drawn, which was attached to the existing construction. Eelke Hofman, project leader at Visser Konstruktie Veenwouden: "We translated the 3D-scan to the drawing work and through production to the construction. All new parts are attached to the building by bolted connections. This has to be well prepared with, among other things, accurate drilling plans, because it has to fit into production and assembly."

Together towards success

"The project consists of three building sections side by side: the existing structure, the new office section and the annex," Hofman continued. "All of this we put into a nice plan. With the main building we are now finished. For the annex building, we are now working on the drawing work."

This is performed for Visser by A&I Kwant. Since she can also scan and the companies often work together, this was also a matter of course here. The companies have also worked with Hesco for years, so the contacts know how to make the project a nice success.