‘Floating’ platform caps for OVT south

The renewal and expansion of the station environment in Amsterdam Zuid is becoming increasingly visible. Sorba tackled the ceiling and roof cladding of the striking platform covers, which appear to float above the platforms due to the special aluminum composite cladding in a high-quality finish.

The new platform covers replace the existing structures above the tracks. “Working closely with steel fabricator Buiting Staalbouw, we are providing the aluminum composite cladding around the hoods, including the visible side at the bottom,” says Ken Rouwenhorst, project engineer at Sorba. “This involved choosing a metallic color with Lumiflon coating, carefully selected by the architect. All seams and substructures are optically black, creating a sleek and uniform image and making the caps appear to float, as it were.”

Custom made

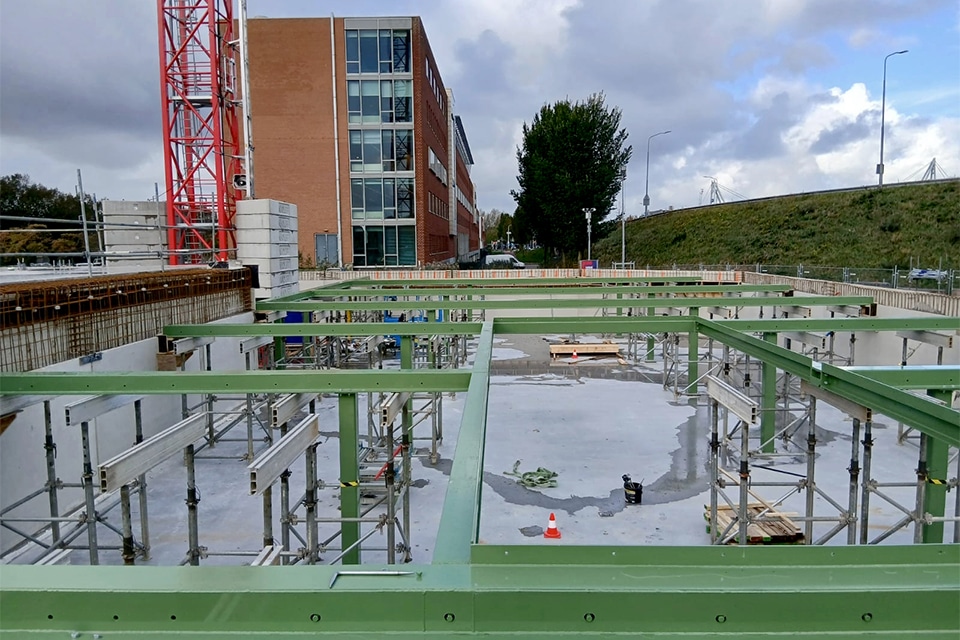

The project is broken up into phases: each platform cap is prepared separately at the steel fabricator, brought to the site in segments and hoisted in one weekend. Sorba also does much of the preparatory work in-house. “At our facility in Winterswijk, the 6 mm Alpolic aluminum composite cladding is cut to size and assembled. We then take the material to Buiting Staalbouw for further assembly. At least, that only applies to the sheeting that is not in the way for transport,” Rouwenhorst explains. “After the scaffolding is placed at the station, we take care of the further finishing.”

8,500 m² of cladding

In total, Sorba is delivering as much as 8,500 square meters of sheeting for the first phase, spread across four platforms with roofs 140 meters long and up to 14 meters wide. “One of the biggest challenges was in the design. Originally, a separate nose profile was planned, but because of aesthetics and the risk of color difference, we proposed an alternative: a solution where the whole thing consists of one material. The 40 mm radius in the panels also required customization; a relatively small radius that is not common in composite processing. But it is precisely this that gives the hoods the desired slender, almost floating appearance.”

Business card

The first canopy has now been successfully installed and is a calling card for the next phases. Work will continue until mid-2026, when the last canopy will also be completed. Sorba, by the way, is a familiar face at our home stations. “With our experience from previous public transport projects, including Breda, Arnhem, The Hague and Amsterdam, as well as platform caps at Utrecht CS, Arnhem CS and Amsterdam RAI, among others, we bring specific expertise for building in railroad environments.”