Work preparation is pivotal in successful facade projects

Optimal monitoring of quality, schedule and budget. But above all: the very best facade design. Facédo likes to be involved in projects as early as the design phase. For example, to harmonise feasibility and affordability with excellent aesthetics and realistic planning. The new building of The Blox in The Hague is a fine example of this.

On former industrial estate De Binckhorst, VORM Bouw will start construction of The Blox in July 2024: a 130-meter-high residential tower with unusual architecture, great attention to nature and a rare quality of living. The residential tower will consist of six blocks of sixty homes that together form a neighborhood or residential community. In total, over 38 floors, the residential tower will provide space for 360 rental apartments for first-time and transitional buyers, as well as a plaza, green courtyard gardens and a 2,100-square-meter communal urban rooftop park on top of the parking garage.

Element façade

The Blox will have a precast concrete shell, making the 130-meter-high residential tower faster to complete and thus more affordable. Because the structural precast floors are separated from the installations, the layout is flexible. The tower can adapt to the needs of our time. Also special is the element façade, which is industrially developed and completely demountable (circular). At the basis of this facade are the approximately 13,483 m2 wood-frame elements of WVH Gevelprojecten, which are just-in-time and including 7,710 m2 of aluminum composite cladding, 1,966 m2 of profile plate, 15,515 m1 box sections and 1,200 Facédo aluminum window frames were delivered to the project. “By now, the window frames for the first two blocks have been built into the HSB elements,” says work planner Mart Janssen. “The window frames for the third block will follow in early 2026.”

Faster and more efficient

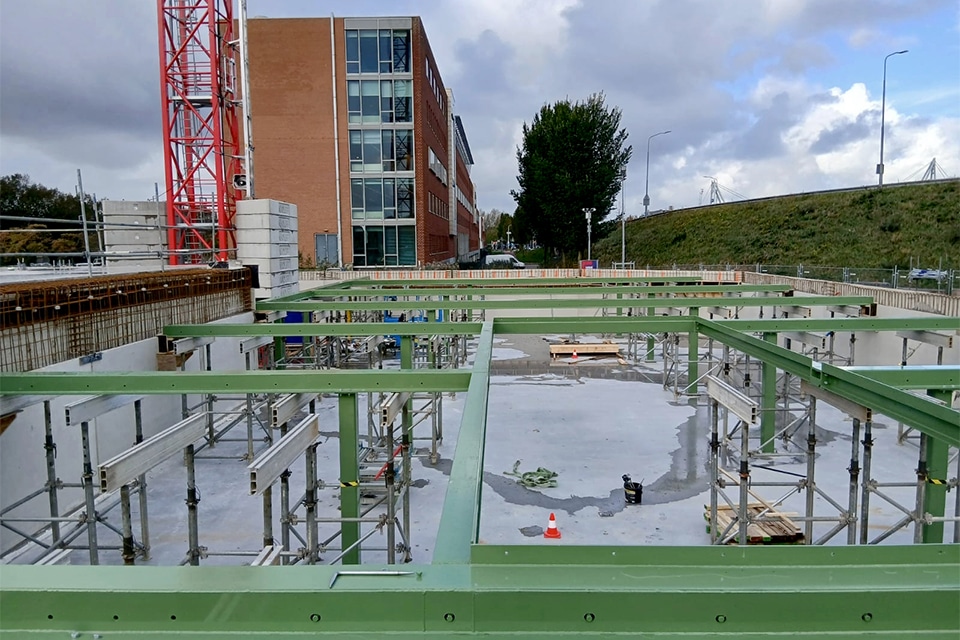

On behalf of VORM Bouw, Facédo is realizing a total of 8,500 m2 of aluminum window frames, based on the Kawneer RT 72 system. But also 700 m2 of aluminum curtain walls. “Approximately 400 window frames will be pre-populated and traditionally assembled by us,” says Janssen. “The bulk of the frames, however, are prefabricated. In WVH Gevelprojecten” assembly line, our window frames are already built into the HSB elements. This is a major advantage in a high-rise project such as The Blox, because in this way construction can be much faster and more efficient. After all, all the facade elements are delivered to the project ready-made and just-in-time, hoisted to the right floors in one go and assembled without scaffolding."

Streamlined design

To ensure that construction can continue unhindered, it is important that all façade elements are produced well in advance, Janssen says. “For example, the elements that are currently being hoisted in were assembled six months ago.” Says project manager Bram Leijser, “Together with WVH Gevelprojecten, we have engineered the project in detail. For example, with regard to wind and water tightness. Earlier this year, we also conducted a successful wind and watertightness test in our test cabinet in Velp with a mock-up frame, including associated details such as ceiling, wall and floor connections.”

Most efficient method

WVH Facade Projects and Facédo also examined the most efficient way of working. “By supplying new window frames on a weekly basis, inventory remains limited and assembly orderly,” Leijser says. “Thanks to our early involvement, we also had ample time to purchase materials efficiently. But also to put together the right assembly team, with guys from the neighborhood. As a result, the lines are literally short and we can switch quickly and flexibly.”

Completely involved

This includes an important role for the work planner, who is involved from the initial drawing through to job preparation, production, assembly and delivery. “This really makes the work planner the linchpin in the process,” Leijser and Janssen said. “A challenging responsibility, where our work planners are given all the space they need to perform their tasks in their own way. But also the time to work out projects properly.”

From work planner to project manager

Meanwhile, Janssen is advancing to project leader. His first project is Nimwest in Nijmegen. A great opportunity, which perfectly illustrates the development opportunities within Facédo, he says. “In combination with the growth Facédo is experiencing, we are looking for new work planners to join our team.” What is important about these work planners is that they have (facade) construction experience, are flexible and have passion for their profession. “In addition, they must be strong communicators. After all, they have direct contact with our clients.” In return, the work planners come to work at a young, friendly and dynamic company with great colleagues, excellent working conditions and a very interesting project portfolio.