Total supplier for precast concrete

Cascade walls, structural walls, concrete plinths, insulated walls, fire walls, interior walls, columns, hollow-core slabs, it has all been prefabricated at Preco's new concrete plant for the past year and a half. The company is thus responding to the increasing demand for efficiency in the construction industry and is emphatically positioning itself as a total supplier of precast concrete. Clients can outsource the care of the complete concrete shell to Preco.

Text | Roel van Gils. Image | Preco

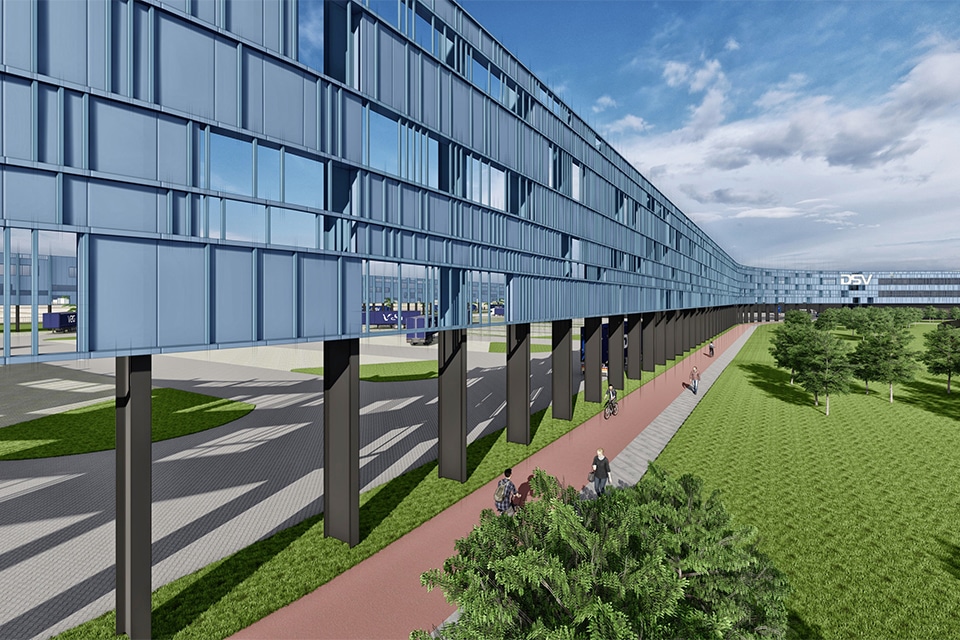

The new production facility in Apeldoorn is equipped with state-of-the-art technology and a state-of-the-art concrete plant. "Besides the engineering and production of the elements, we also provide transport, whether just-in-time or not, and even assembly is among the possibilities," says commercial director Theo Kool. "One address and one point of contact has its advantages. Clients therefore knock on our door for the production of precast concrete elements for complete new construction projects. We are active in utilities, such as distribution centers and office and industrial buildings, but recently we have also been producing more and more for hotels and apartment complexes."

One point of contact

Currently, the production facility is running at full capacity. "We are busy producing elements for two Van der Valk hotels, one in Schiedam and one on the A4 in Hoofddorp, among others," Kool says. "That first one in particular is a special story. Initially the intention was to pour the eighteen-story hotel on site, but for reasons of speed it was converted to precast. We are also producing balconies, gallery slabs, stairs and structural walls for apartment complex De Ananas in Leiden and have been selected to supply the precast concrete elements for a beautiful new building on the campus of the University of Wageningen. In short, a great diversity of projects to which we are contributing. The fact that we can take care of everything in-house as a total supplier, so one point of contact, is of great added value for many clients."