Sustainable distribution center for AG Logistics

AG Logistics Services is a logistics service provider with several offices in the Netherlands. The head office is located in Lunteren. The company deals with goods handling, transport and Value Added Logistics, or services that add value to the logistics process. It is a growing family business. To keep up with this growth, the company is investing in two new distribution centers, in Ede and Oosterhout.

The sustainable distribution centers should be completed in 2021. The building in Ede will be built on the BTA12 industrial estate, on the Daltonstraat. It will be built under BREEAM with 'Excellent' as the minimum requirement. The ambition is to achieve 'Outstanding'.

Sustainability guaranteed

To achieve this short construction period and sustainability requirement, first of all, subcontractors were selected that are themselves certified in sustainability, says Denny Beker of HBE Circular Construction. "For example, CSC concrete will be used, which guarantees sustainable production. We selected parties from the neighborhood as much as possible, to reduce CO2 emissions from travel movements. In addition, a sustainable installation is being used, with a heat pump for the distribution center and one for the office area, combined with solar panels. High insulation values and solar control glazing have also been provided so that it does not heat up too quickly inside. The steel structure is clad with roof and wall cladding."

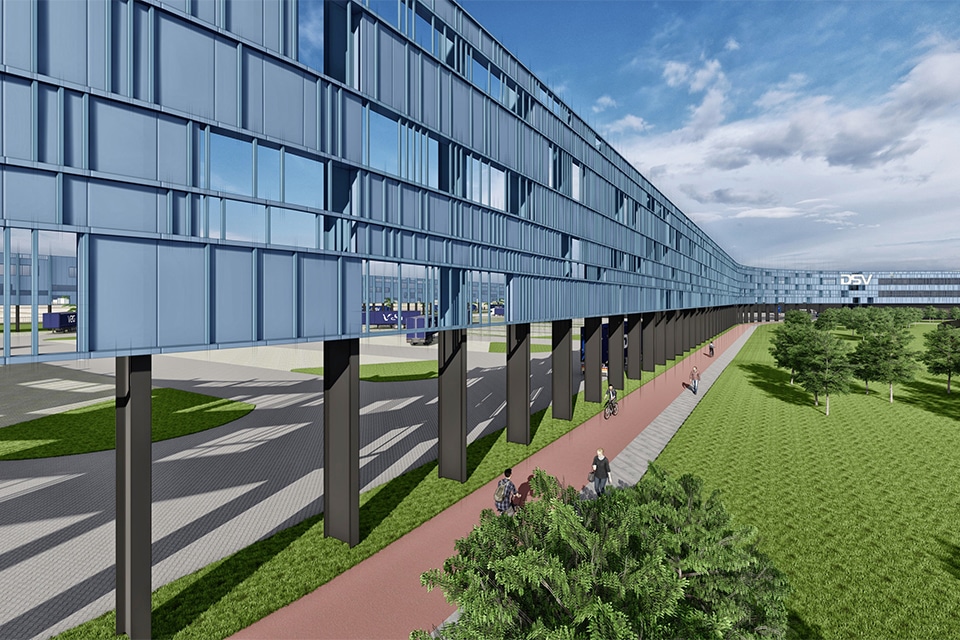

Curves

The unusual shape of the plot provides an additional challenge. For the plot is not simply square, but tapers. Therefore, the architect has given the building extra curves and corners so that the ground surface is used optimally. Beker: "For the structural engineer and the men on the construction site, that brings challenges. There are many curves in the building, so the flashing, foundation and cladding needed extra attention. For example, precast concrete elements had to be rounded by the supplier."

Four stars a must

Currently, construction is right on schedule. It was known in advance that the construction period would be short, and cooperating parties were made aware of this early on. "On Oct. 8 we received the permit and on Oct. 9 we started construction. That went smoothly, with no delays in deliveries," Beker says. In between, construction meetings are taking place with the people from BREEAM. "We had inspection of the construction and they were pleased with it. We can achieve a BREEAM certification of between one and five stars. The client thinks it's a must to get four stars and that's definitely going to happen."

Facts & Figures

- 42,000 pallet spaces

- 30,000 m² of floor space

- 29,000 m² of steel roofing sheets

- 2,300 m³ concrete foundation

- 25,000 m³ of sand removed

- 120,000 tons of debris processed

- 1,520 tons of steel

Project info

Cladding is home game

AG Logistics' new distribution center in Ede is wind and watertight, thanks in part to the cladding from "neighbor" FALK Bouwsystemen.

"HBD Montage has given us the opportunity to enter this beautiful project together with us," says Dennis Jordaan of FALK Bouwsystemen. "For us also a great opportunity to also show the 'neighborhood' what beautiful panels we make. After all, the construction site is about 500 meters next to our production line. The product chosen was the FALK Facade Panel 1060 WB with a tight micro-rib lining. The sandwich façade elements were installed by HBD Montage in a concealed manner. The high-quality PRISMA® coating on the panels, executed here in two different colors in combination with the micro-rib lines, give the new distribution center an attractive appearance. We are therefore proud of the fact that we were able to supply over 12,000 m² of façade panels to a project nearby, also with the highest sustainability ambitions."

Construction Info

Main contractor HBE Circular Construction, Ede

Installation of roof and wall panels HBD Montage, Ede

Delivery of cladding FALK Bouwsystemen, Ede

Delivery of roof panels Van Delft, Waalwijk

Applying roofing Kamil Dak, Tilburg

Places steel Steel Construction Cluistra, Renswoude

Delivery CSC concrete Concrete plant Wessel

Processing concrete Van De Haar Concrete Construction, Ede

Reinforcement nets Schreuder Reinforcement, Barneveld