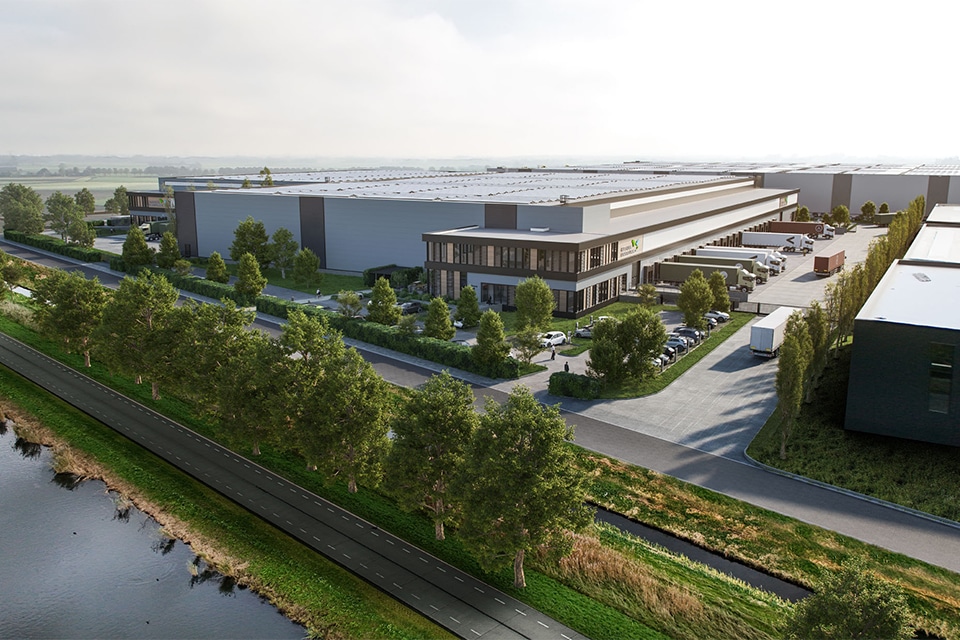

Final piece of development mega-distribution center

On the Rotterdam Logistics Park in Hellevoetsluis, Heembouw is adding an important new chapter to the large-scale logistics development for client Delta with the completion of building sections A and D. After the successful completion of building sections B and C, also by Heembouw and together representing around 45,000 m2, building sections A and D form the final part of a total project of around 100,000 m2. The new building aims to achieve BREEAM Excellent, with a focus on both energy performance and circularity.

Building sections A and D are all about innovative energy solutions, says Raymond Plasmans, project manager at Heembouw. “Due to grid congestion in the region, a conventional grid connection was insufficient. In collaboration with energy partner Joulz, an off-grid configuration was therefore chosen: a combination of an extensive battery pack, solar panels on all roofs and a standby generator. This solution guarantees a reliable energy supply without being dependent on the overloaded electricity grid. In doing so, the project effectively acts as a future-proof energy island.”

Detachability

“The building components consist of a steel structure surrounded by a facade of sandwich panels,” explains Germen Bakker, project manager at Heembouw. “For the steel structure, we are using XCarb recycled steel, produced via an all-electric process with minimal CO2 emissions. Furthermore, inside we are creating a mezzanine with hollow-core slab floors and high-quality office spaces. The roofs are constructed with TPO roofing and fully FM Approved, ensuring a high degree of safety and fire resistance.” Plasmans adds: “The buildings were designed according to the principle of ‘design for disassembly.’ The columns are not embedded in concrete, the roof plates are screwed instead of shot and parts can be easily disassembled.”

Circularity

Various elements were selected according to the Cradle to Cradle philosophy, such as reusable tiles, gypsum concrete panels, window frames, glazing, roofing, sanitary ware pieces and system ceilings. “With every material choice, active advice was given to the client to ensure the circular ambitions,” Bakker emphasizes. Beneath the building components lies a heavy foundation with HSP piles up to 23 meters long. The very poor bearing capacity of the subsoil was one of the biggest technical challenges of the project, according to Plasmans, combined with the planning and limited availability of piling rigs for these pile lengths. “The poor subsoil is also the main reason we ‘lifted’ the building slightly. For example, the loading docks are at ground level, a solution that suits the high groundwater level.”

Close cooperation

Both building sections have a tight lead time, according to both men. Thanks to the experience from previous phases, the permanent team of partners and optimal mutual coordination, unforeseen situations were quickly dealt with. “A defective piling rig or logistical setback was not seen as a problem, but as a joint issue to be addressed immediately,” Bakker gives as an example. The close cooperation between Heembouw and its partners and client is therefore named as one of the biggest success factors in this project. “That's where Heembouw makes the difference,” says Plasmans. “We have knowledge of building and work extremely customer-oriented. Give us the freedom and responsibility and we will take care of it. This resulted in building section A being completed on schedule by the end of 2025. Building Section D will follow at the end of March of 2026.”

Apart from BREEAM, Heembouw applies nature-inclusive measures as standard. “We do that with every project,” says Bakker. “Think about the use of green facades, fauna facilities and a quick scan by an ecologist, so that even this mega-distribution center does not harm the habitat of local flora and fauna.”